Project Information

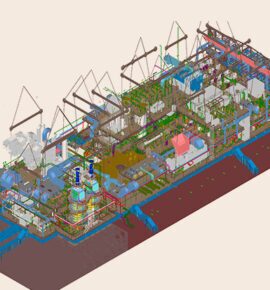

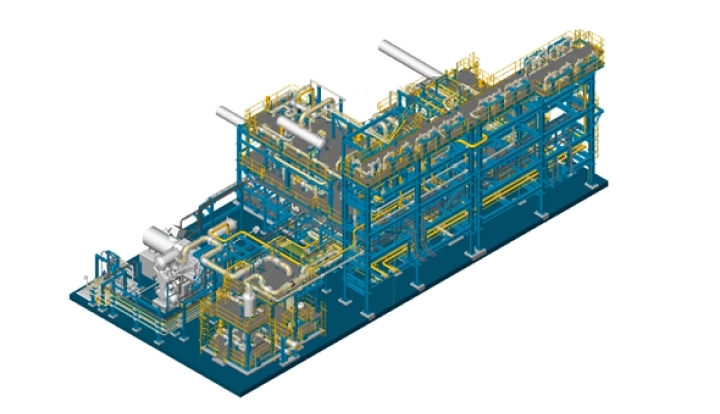

Detailed Engineering Of Multi-Skid Modular Package

Description

Client

An Australia-based EPC/LSTK contractor engaged in large-scale onshore and offshore projects across Oil & Gas, Refinery, Petrochemical, Tank & Storage, Mining, and industrial sectors.

Engineering Requirement

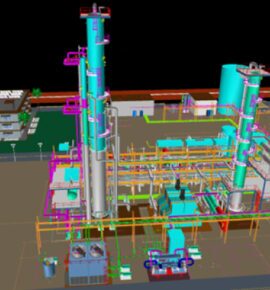

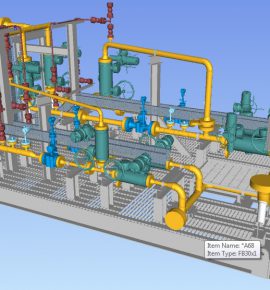

Our client, a leading EPC/LSTK contractor in Australia, required a detailed engineering company to support the detailed engineering of multi-skid modular package of five modular skid packages forming a mission-critical section of a process plant. These included the BOG Vessel Skid, BOG Exchanger Skid, Refrigeration Compressor Skid, Refrigeration Vessel Skid, and PSV Rack. Each module had to be optimized for structural integrity, transportability (road & sea), and compliance with stringent global engineering standards.

Rishabh Engineering was chosen to provide integrated, multidiscipline engineering services to design, model, analyze, and deliver fabrication-ready outputs for all five skids. Our team worked across piping, structural, civil, mechanical, electrical, and instrumentation disciplines to develop a complete 3D model, perform detailed stress and structural analysis, and ensure all skids were safe for transport and operation.

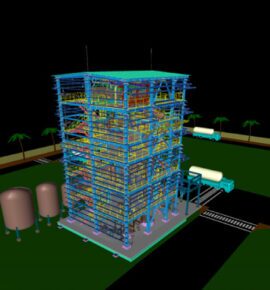

Using CADWorx, CAESAR II, STAAD.Pro, Tekla, and SOLIDWORKS, we addressed project challenges like rework due to late-stage design changes, increased weight from hot-dip galvanizing (HDG) requirements, and lifting complexity across modules. The collaborative phased approach for modular process skid detailed engineering helped maintain project continuity while ensuring quality and compliance.

Deliverables

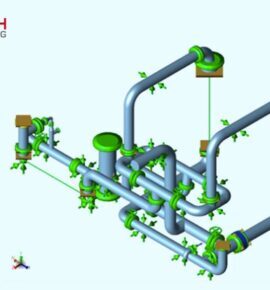

- 3D Model of the complete modular package system

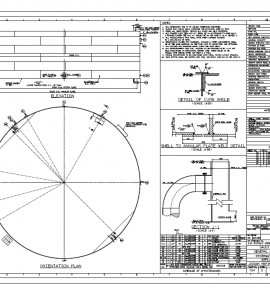

- General Arrangement Drawings (GADs) for skids and overall plot plan

- Piping isometric drawings and vessel trim isos

- Bill of Materials (BOM) and Material Take-Off (MTO) for piping, supports & insulation

- Pipe stress analysis reports and markups

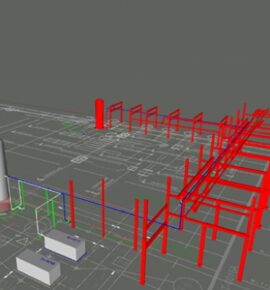

- Structural steel analysis, fabrication drawings, and skid transportation drawings

- Electrical & Instrumentation cable tray layouts and isometric views

- Custom cold shoe support design with FEA validation for cryogenic conditions

- Technical Bid Evaluations (TBE) for vendor equipment selection

- Foundation loads & lifting lug/pad eye calculations

Through collaborative and integrated engineering approach, Rishabh Engineering successfully delivered the detailed design for five critical modular skid packages within 30 weeks. Despite the complexities—ranging from multidisciplinary design rework to weight challenges due to galvanization—our team streamlined execution using advanced software integration (CADWorx, CAESAR II, STAAD.Pro, Tekla, SOLIDWORKS) and agile coordination strategies. The result was a set of structurally robust, operationally efficient, and fabrication-ready modules that met all client specifications and international standards. This case exemplifies Rishabh’s capability to deliver modular process engineering solutions under tight timelines and complex requirements.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent blogs

View all