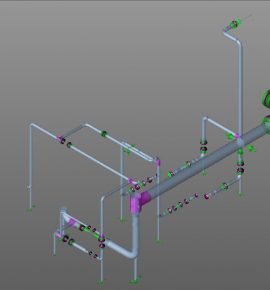

Piping Stress Analysis Services

As a five-time Hexagon Elite award-winner, we offer comprehensive pipe stress analysis services to evaluate the structural integrity and flexibility of piping systems under various operational and environmental conditions. Our experienced team ensures that stress levels remain within permissible limits to prevent failures and meet global standards like ASME B31.3, B31.1, B31.8, and more.

Our pipe stress analysis expertise spans diverse industries and their applications, allowing us to identify potential stress issues early in the design phase and support in implementing effective mitigation strategies. We use industry-leading tools like CAESAR II, and more to deliver accurate, reliable results that support safe operations and long-term performance.

Types of units for which we have successfully undertaken stress analysis of piping systems include:

Software / Tools/ Technology

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Cryogenics

Metals & Mining

Pharmaceuticals

Sugar

Fertilizers

Semiconductor

Industry Codes and Standards adhered to by our Designers

ASME B31.1, B31.3, B31.4, B31.8, B31.11, BS EN 13480, BS EN 14364, Shell DEP, ISO 14692, EN13480, DNVGL-RP-D101, PED Directives, ASCE, IS 875/1893, BP, ARAMCO, ADNOC

65,000

Man-Hours of Project Executed

10 Years

Of Team Experience

ISO 9001 & 27001

Certification

Our Pipe Stress Analysis Services

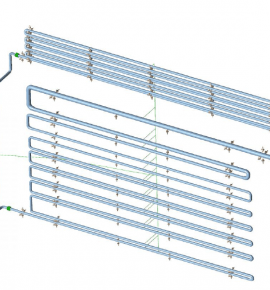

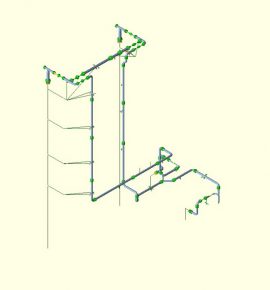

Rishabh Engineering team delivers end-to-end piping stress analysis services tailored to the specific requirements of our clients. From early conceptual design through to detailed engineering and construction support, we help EPCs, plant owners, and OEMs ensure piping system integrity and performance. We specialize in analyzing stress due to thermal expansion, internal/external pressure, seismic activity, wind loads, vibration, and other dynamic conditions. Our engineers conduct static & dynamic analysis and finite element analysis (FEA) while providing actionable recommendations such as routing modifications, selection of right support anchor location changes, and expansion loop designs to enhance system flexibility and code compliance.

Listed below are our focused pipe stress analysis services;

- Thermal Flexibility Assessment

- Evaluate pipe stress and movement under thermal cycles.

- Recommend expansion loops or supports to absorb displacement.

- Ensure code compliance (ASME B31.1, B31.3) for temperature-induced loads.

- Load Case Evaluation

- Analyze piping for sustained loads like weight and internal pressure.

- Evaluate occasional loads from wind, seismic, and equipment actions.

- Identify critical stress points and support adjustments.

- Dynamic Stress Analysis

- Assess mechanical, flow and acoustic induced vibrations.

- Perform modal, harmonic, and time-history analysis.

- Recommend solutions to mitigate fatigue and resonance failures.

- Transient Force Analysis

- Identify peak forces from sudden fluid momentum changes.

- Evaluate effects of valve closures and two-phase flow surges.

- Suggest pipe anchoring, routing and surge suppression strategies for stability.

- Support System Design

- Determine optimal support type and spacing for load control.

- Design spring hangers, guides, and restraints to limit deflection.

- Ensure system flexibility and load transfer balance.

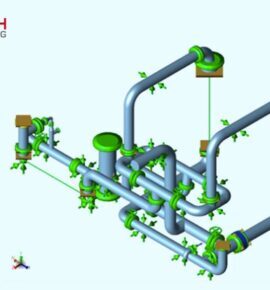

- Nozzle Load Verification

- FEA for Nozzle, Trunnions, Special Pipe Supports, Miters, Bends and more

- Analyze allowable loads on connected equipment nozzles.

- Prevent overloading and misalignment issues on rotating/static equipment.

- Coordinate with vendor data to ensure mechanical integrity.

- Piping Design Optimization

- Streamline pipe routing to reduce stress and material cost.

- Propose layout changes for better flexibility and accessibility.

- Enhance system performance through cost-effective solutions.

- Stress Report Generation

- Generate detailed isometric drawings with stress annotations.

- Document load cases, displacements, and restraint forces.

- Provide clear code compliance summaries for client approval.

- Failure Cause Analysis

- Investigate thermal, mechanical, or fatigue-related pipe failures.

- Use reverse modeling and field data to diagnose root causes.

- Recommend practical mitigation and repair strategies.

- 3D Integration Review

- Integrate stress analysis results with 3D plant models (Navisworks, PDMS, E3D).

- Identify and resolve piping clashes and interference zones.

- Facilitate multidisciplinary coordination and constructability reviews.

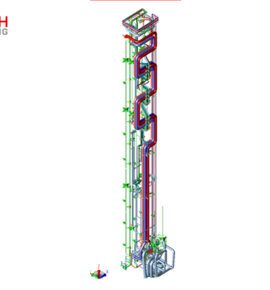

As a pipe stress analysis consultant, we perform pipe flexibility and stress analysis for the following piping systems.

- Tank Farm Piping

- Process Plant Piping

- Duct Piping

- Heat Exchanger Piping

- Boiler Piping

- Pump Piping

- Underground Piping

- Glass and Fibre Reinforced Piping (GRP/FRP)

- Gas & Oil Metering Skids

- Flare Packages

- Fired Heaters

- Fire Fighting Systems

- Cryogenic Systems

- Column Piping

- Reboiler Piping

- Compressor Piping

- Turbine Piping

- Cold Box Piping

- WHRU Piping

Ready to Get Started?

Why Choose Us As Your Pipe Stress Analysis Company?

We are a five-time recipient of Hexagon’s Asset Lifecycle Intelligence (ALI) division’s prestigious award (formerly Drivers of Success), recognizing our pioneering use of Hexagon software to deliver project excellence across complex customer requirements.

Our team offers a multidisciplinary approach to piping design and engineering, ensuring holistic project success.

We adhere to international codes and standards, delivering reliable and safe piping systems.

Over a decade of experience in delivering successful piping engineering projects across industries and geographies.

CUSTOMERS FEEDBACK

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)