Project Information

Basic and Detailed Engineering For Chemical Processing Plant

Description

Client

An India-based manufacturer of chemicals and specialty chemicals used in the downstream manufacturing of agrochemicals, polymers, additives, surfactants, pigments & dyes.

Engineering Requirement

For an upcoming chemical processing facility in Western India, our client sought comprehensive engineering design and procurement support across multiple disciplines to optimize operational efficiency and advance production capacities according to industry standards and best practices.

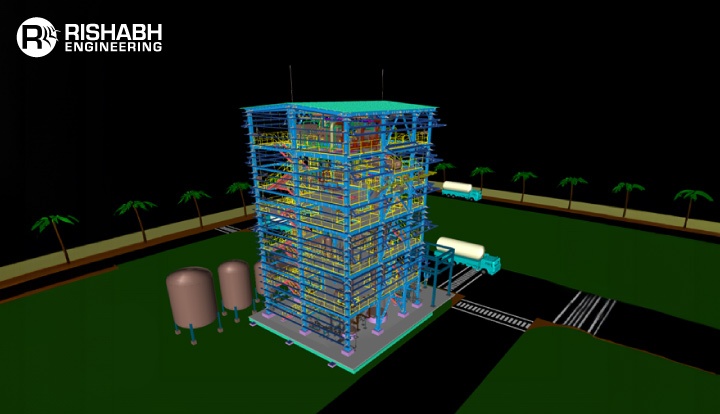

Our detailed engineering services team covered the entire project lifecycle, ensuring meticulous attention to detail and seamless execution from inception to completion. Key activities included:

Process Engineering:

- Hydraulic calculations

- Process datasheet development

- P&ID updates

- 3D modeling

- Technical specification creation

Mechanical and Piping Engineering:

- Generating GA and isometric drawings

- Conducting model reviews

- Preparing BOQs

Civil & Structural Engineering:

- Designing structural steelwork

- Foundation design

- MTO preparation

Electrical Engineering:

- Establishing load lists

- Creating single-line diagrams

- Cable sizing

- Designing lighting layouts

Instrumentation Engineering:

- Developing control loop diagrams

- Creating JB schedules

- Cause & effect diagrams

Additional Tasks:

- Fire hydrant system design

- Comprehensive procurement assistance

Want to know more about this project?

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)