Project Information

Design and Engineering of Process Control Modular Skid Package

Description

Client

A renowned US-Based organization that enables companies from manufacturing and process industries with highest levels of process control expertise, automation products and lifecycle services.

Engineering Requirement

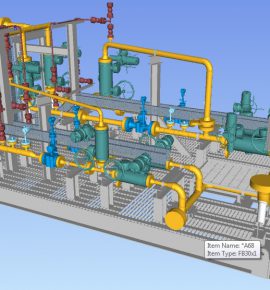

As a trusted modular process skid design company, Rishabh Engineering carried out engineering and design of process control skid package. We were engaged for creating an intelligent 3D Model, fabrication drawings and perform structural stress analysis service for process control modular skid.

The overall scope for this project included;

Piping:

- 3D Modeling

- General Arrangement Drawing of the Skid Package

- Generating Piping Bill of Materials

- Fabrication Drawings of Base Frame & Pipe Supports

- Isometric drawings of Mainline & Small-Bore piping

- Spool Drawings

- Weld Map drawings

Structural Analysis:

- In-Place Analysis as per AISC 360-16

- Lifting Analysis

- Transit Analysis a per CTU Code

- Anchor Bolt Calculations

- Lifting lug Calculations

- Designing the connections

Delivered

- Final 3D Model of The Skid

- Final General Arrangement Drawings

- Piping Isometric Drawing (approx. 80 nos. of sheets)

- Spool Drawings (approx. 80 nos. of sheets)

- Detail Drawings of Base Frame

- Detail Drawings of Structural and Pipe Supports

- Piping & Structural MTO

- Lifting & Transportation General Arrangement Drawing

- Structural Analysis & Calculation Report (In-place analysis, Lifting analysis, Transit analysis)

- Anchor Bolt Layout & Foundation Load Data Drawings

- Foundation Load Drawings and Anchor Bolt Calculations

- Structural Fabrication Drawings

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)