3D Modeling Services

As an award-winning 3D modeling company, Rishabh Engineering offers a full range of multidisciplinary plant modeling services. Our team of expert CAD professionals and design engineers collaborate with EPCs, engineering consultancies, and OEMs to deliver quality 3D modeling services. With extensive on-site experience, they create real-life walkthroughs as digital models, offering a comprehensive understanding of the facility before the construction begins.

We’ve worked together with many well-known clients from USA, Canada, EU, MENA and APAC regions. As their outsourcing partner for 3D design services, we ensure quality in deliverables with timely delivery. Our active work engagement is based on complete transparency.

Based in India, our team of qualified engineers, CAD designers, draftsmen and project planning managers dedicatedly work on client projects with utmost collaboration to create drafts and make amendments quickly till the desired quality is achieved. So, whether you would like to build a 3D model to better visualize the basic concept, design and output of the facility, you’ve come to the right place. We are happy to assist you and provide solutions.

Software / Tools/ Technology

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry Codes and Standards adhered to by our Designers

BEST APPLICABLE INDUSTRY STANDARDS

55,000

Man-Hours of Project Executed

20+ Years

Of Team Experience

ISO 9001 & 27001

Certification

Service Offerings

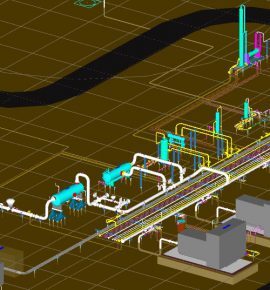

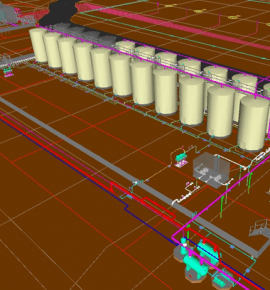

3D CAD Services for Modeling

- Project Setup as per client specs

- Preparation of Mechanical Data Sheets, Equipment Layouts &Vendor Data Collaboration

- Modeling of civil/structural elements such as equipment foundations, platforms and walkways (or Ladders, Handrails, Manholes, Envelopes, Pipe Racks, Skid Base-frame/Lifting Lugs, or Anchor Bolts), with input from detailed 2D drawings in CAD format

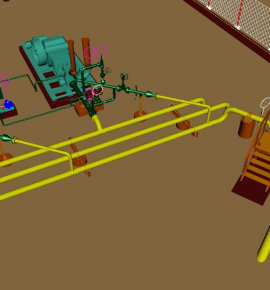

- Piping and pipe support modeling as per GA drawings in 2D AutoCAD format

- Physical support modeling using 3D Design tools as per the support standards provided

- Modeling of instruments, junction boxes with support, and cable trays, as per the electrical and instrumentation layout in 2D drawings in AutoCAD format provided by clients

- We create accurate industrial 3D modeling and design of utility buildings such as control rooms, motor control center (MCC) buildings, fire safety stations, and more

- The multi-disciplinary 3D CAD Design Model helps implement the extraction of equipment layouts, general arrangement drawings, piping isometrics, nozzle orientation drawings, fabrication drawings, and material take-off (MTO)/bill of materials (BOM)

Ready to Get Started?

What to expect when you work with us

We provide accurate design visualization before finalizing the construction that helps communicate the change in the design if any as per the plant requirement.

We have delivered 3D CAD modeling solutions across 15+ countries with the help of our unparalleled expertise in the domain.

Single file access to extract all layouts, cable routing, GA, isometric drawings, BOM, steel, architectural drawings, and other documents in one place. This enables minimizing the concept-to-production time.

Our team helps get accurate and reliable results by creating high-quality, accurate, and modifiable 3D designs and drafts and detecting defects early.

CUSTOMERS FEEDBACK

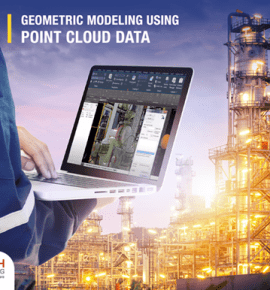

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)