Project Information

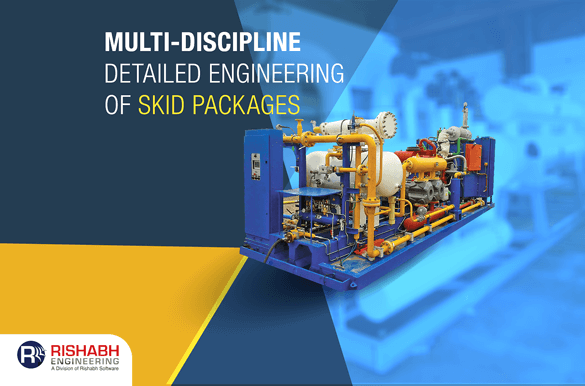

Multi-discipline Detailed Engineering of Compressor Skids, Chiller Skid and Condenser Skid Package for FPSO Platform

Description

Client

An EPC contractor who provides process cooling, gas compression, natural gas processing, and tank cooling solutions for Oil & Gas and Downstream industries. It also provides skid mounted packages, process design, consulting services & detailed engineering.

Engineering Requirement

Rishabh Engineering assisted the client with skid package design for the skids to be installed on the FPSO platform along with the submission of the associated drawings by complying with their specifications. We were responsible for the following:

- To ensure that all design requirements are met considering human factors engineering for equipment access, maintenance, and safety

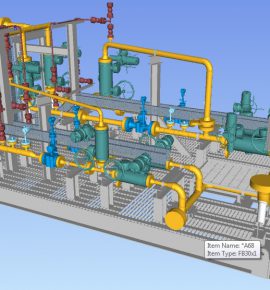

- To provide a 3D model for 30%, 60%, and 90% model reviews

- To incorporate all piping and structural analysis inputs

- To extract General arrangement drawings, ISOs, MTOs and other documents as deliverables for issue

- To prepare manufacturing drawings

Delivered

- 3D Model

- Piping Stress Analysis

- GA Drawings with Nozzle Loads

- Piping Isometrics

- Piping Insulation MTO

- Structural Stress Analysis

- CoG Calculation Report

- Anchor Bolt Calculation

- Lifting Drawings

- Piping/Structural/E&I MTO

- JB & Instrument Location Layout

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)