Project Information

Fired Heater Design and Detailed Engineering

Description

Client

UK-based fired heater simulation technology & engineering services provider

Engineering Requirement

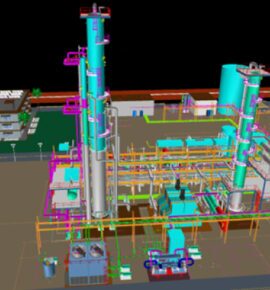

Our client sought a detailed engineering partner to develop a fired heater module for Alaska’s seawater treatment plant (STP). The heaters were essential for maintaining the temperature of ethylene glycol. They were to be fabricated and mounted on a barge for transport through the Atlantic Ocean before integration into an onshore waste heat recovery plant.

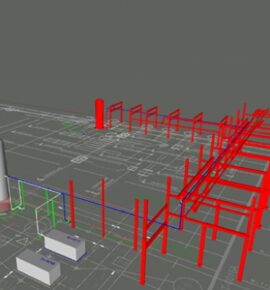

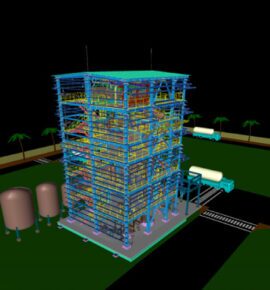

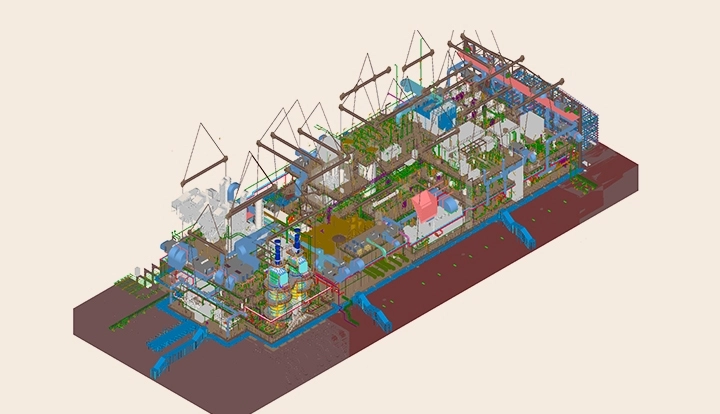

Rishabh Engineering was selected to provide comprehensive fired heater design and engineering services. Our team utilized CADWorx and Tekla to create a detailed 3D model of the heater, allowing for effective visualization and early identification of potential design issues. The piping team performed comprehensive piping analysis using CAESAR II, while structural analysis was completed with STAAD.Pro Connect Edition. Based on these analyses, we provided recommendations for design improvements.

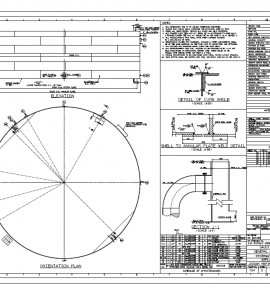

Our team collaborated closely with the client throughout the direct-fired heater design project to ensure alignment with specifications and timelines. Key deliverables included the 3D model, General Arrangement (GA) drawings, piping, and structural analysis reports, lifting and transportation drawings, as well as detailed bills of materials for both structural and coil components.

Deliverables

- 3D Model of Heater Native file.

- Heater GA Drawing

- Piping Analysis Report

- Structural Analysis Report

- Structural Fabrication drawings

- Lifting & Transportation Drawings

- Foundation load & Anchor Bolt location drawings

- Coil detail drawing

- Structural Bill of Material

- Coil Bill of Materials

- Structural MTO

- 3D Model (Tekla structure)

The client appreciated our team’s expertise and the high quality of our work with direct-fired heater design and engineering. They specifically noted the thoroughness of our approach during the 30% 3D model review stage, which contributed to the successful execution of the fired heater module. Through our detailed engineering services capability, Rishabh Engineering delivered effective design packages that met the project’s requirements, thus enhancing operational efficiency at the STP.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

inquiries@rishabheng.com

Our Offices

USA, UK & India (Head office)