Project Information

FEED and Detailed Engineering For Instrumentation Air System

Description

Client

A US-based engineering and consulting firm specializing in process plant design, project management, and engineering services. They provide comprehensive solutions for the petrochemical, refining, and energy industries.

Engineering Requirement

The client’s utility consumption survey revealed a shortfall in instrumentation air capacity. They aimed to install a new instrument air compressor and auxiliary equipment to address this. Additionally, they recognized the need to optimize the compressor’s capacity, particularly in relation to the desiccant dryer’s regeneration requirements, through comprehensive Front-End Engineering & Design (FEED) and detailed engineering for plant instrument air systems.

Listed below is the scope of work executed with the Instrument air package FEED and detailed engineering.

FEED Scope

- Develop RFQ package including API 619 Datasheet.

- Issue RFQ packages to client-approved vendors and analyze proposals.

- Provide purchase order recommendations with documentation to clients.

The FEED scope also included following activities:

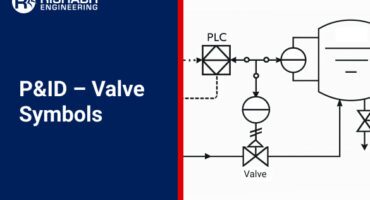

Process

- Piping and Instrumentation Diagrams (P&IDs)

- Cause and Effect Diagrams

- Operating and Control Philosophy

- Hydraulic Calculations

- Air Receiver Sizing

- PSV Sizing and Datasheet

- List of Utility Consumption

Mechanical & Piping

- Equipment and Process Datasheets

- Line & Tie-in Schedule

- Major Equipment List

- Piping General Description

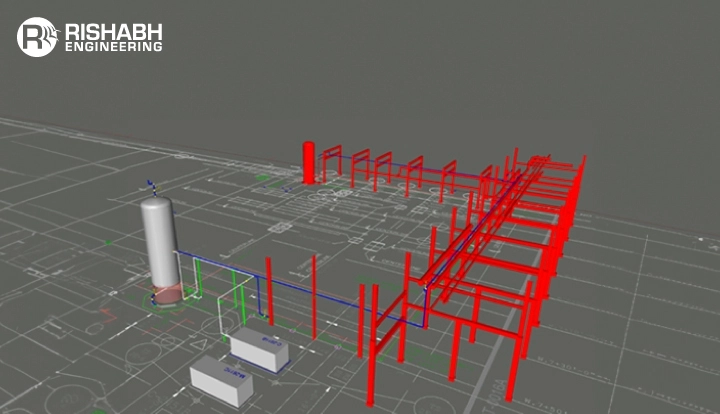

- General Arrangement Drawings

- Preliminary Plot Plan

Electrical

- Electrical Load Analysis

- Power Consumption

- Single Line Diagrams

- Area Classification Drawings

- Grounding Plans

- Power Distribution Requirements

- Emergency/Backup Power Philosophy

- Generator Sizing

- Electrical Simulations

Instrumentation and Control Systems

- Control System Philosophy

- Instrumentation System Philosophy

- Shutdown System Philosophy

- Fire and Gas Detection Philosophy

- I/O List

- Instrument Index

- Instrument Specification Sheets

- Custody Metering

- Power Control Room Details

- Preliminary Instrumentation BOM

Civil & Structural

- General Description

- Geotechnical Report Review

- Preliminary BOM Summary

Detail Engineering Scope

- Based on Field Survey, FEED Study, and Vendor Requirements

- Prepare requisition packages for procurement and construction

- Conduct Site/Field Surveys

- Review deliverables with the client

The detailed engineering scope also included following activities:

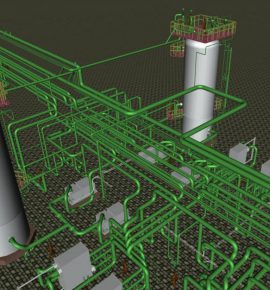

Process

- Diagrams and Lists

- Design and Specifications

- Calculations and Manuals

Civil & Structural

- Specifications and Criteria

- Drawings and Layouts

- Detailed Designs

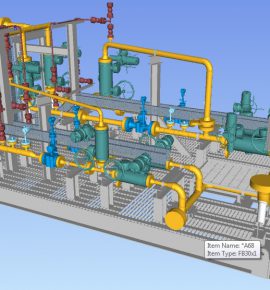

Mechanical & Piping

- Plans and Layouts

- Specifications and Details

- Equipment and Supports

Electrical

- Drawings and Layouts

- Schematics and Diagrams

- Specifications and Manuals

Instrumentation and Control Systems

- Diagrams and Layouts

- Specifications and Indexes

- Schedules and Schematics

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

inquiries@rishabheng.com

Our Offices

USA, UK & India (Head office)