Structural Analysis Services

Rishabh Engineering’s expert engineers are proficient in analyzing the impact of external focus on static structures, such as construction components, machine components, and more. Our highly skilled engineers offer structural analysis services to ensure that these modules meet fatigue safety requirements.

Our structural and stress analysis specialists help simulate the movement of non-stationary objects in vibration analyses, lifting analyses, and other services. With our technology and experience in structural stress analysis, we quantify and further rectify failures in the structure of components that do not meet the proposed design plan, which could result from improper use of materials or even flaws in the manufacturing process.

Software / Tools/ Technology

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry Codes and Standards adhered to by our Designers

ANSI, AISC, UBC, IBC, ASCE, ACI, BS, IS

20,000

Man-Hours of Project Executed

10 Years

Of Team Experience

ISO 9001 & 27001

Certification

Our Offerings

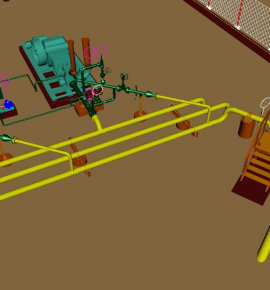

- Structural Analysis : In-service analysis, Pre-service analysis (lifting & transportation) using STAAD.Pro

- Analysis and Design of steel structures for petrochemical plants like pipe rack/pipe bridges, technological structures, specialized packages like metering skids, WHRU units, flare packages, equipment support structure, etc.

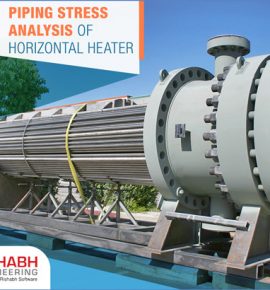

- Foundation Design (Static) of heat exchanger, horizontal vessel (Single/Stacked), vertical vessel, storage tanks, skids, pumps

- Structural design calculations report

- A comprehensive structural analysis are performed as per relevant codes and standards

- Special analysis and design are performed as per project requirement for Blast conditions

- Structural analysis of FPSO topside modules / skids for operating and installation design conditions

- Structural Analysis of Pre-Engineered Buildings: Industrial Sheds, Warehouse, Cold storages, Aircraft Hangers, Industrial Structures consisting Cranes and Mezzanines etc.

- Design of connections & retrofitting of existing structures

- General Arrangements and Erection drawings

- Fabrication & Shop drawings (Single part or Assembly drawings) with BOM

- Lifting & Transportation drawings (as applicable)

- Appurtenance drawings

Ready to Get Started?

What to expect when you work with us

Our structural analysis service helps with accurate identification and fixing loopholes, if any in the product design during early stages of the project to avoid faulty product development and costly reworks.

Our team helps identify and eliminate static stress and displacements to avoid the inefficiency in the product performance.

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

From narrating client or project guidelines and specifications to creating the efficient product and engineering design, we assist in every phase of accurate structural analysis of the safety modules. We also help to simulate non-stationery object movements in vibration, lifting, and other services.

CUSTOMERS FEEDBACK

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)