Project Information

Detailed Engineering Of Crude Distillation Unit

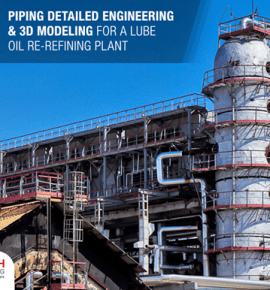

Description

Client

A UAE-based corporation specializing in refining, trading, storage, and bunkering, focusing on providing timely and dependable products. Their modern facilities generate various petroleum distillates, glycols, and specialized solvents.

Engineering Requirement

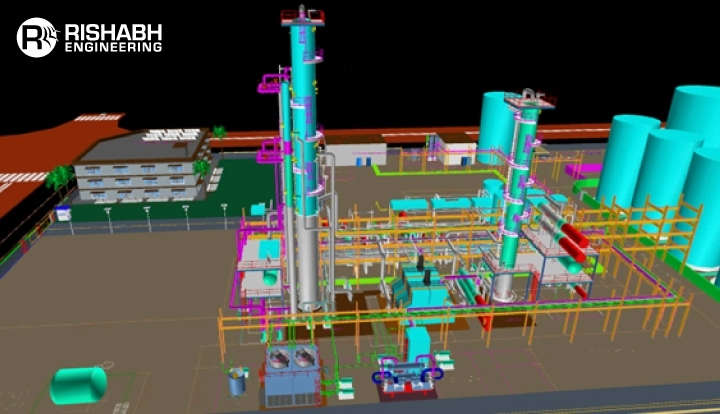

With an integrated and multidisciplinary approach, our team performed detailed engineering of the crude distillation unit for the refinery project. It encompassed various engineering disciplines and project management activities aimed at delivering a robust and integrated design package.

Listed below are the specific activities we performed for the crude oil distillation unit detailed engineering;

- Process Engineering: Conducted a thorough Hazard and Operability (HAZOP) study and updated Process and Instrumentation Diagrams (P&IDs) to ensure safety and efficiency.

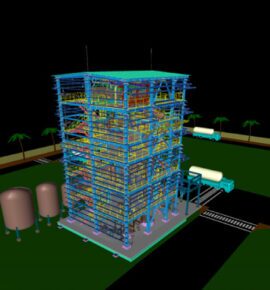

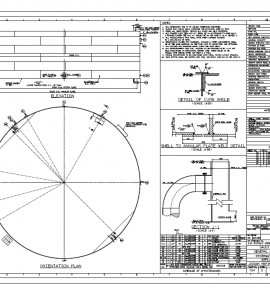

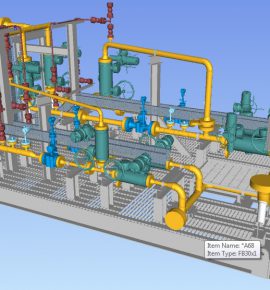

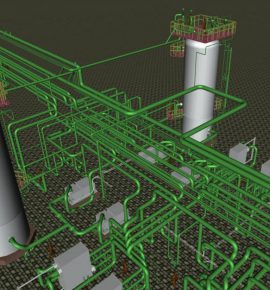

- Mechanical and Piping Engineering: Utilized 3D modeling to design optimized equipment and piping layouts and performed rigorous material and stress analysis to guarantee system integrity.

- Electrical Engineering: Developed detailed system layouts and load lists and prepared Bills of Quantities (BOQs) for all electrical components, ensuring a robust electrical infrastructure.

- Instrumentation Engineering: Designed comprehensive instrument indexes, specifications, and hook-up diagrams to maintain precise control and monitoring.

- Civil and Structural Engineering: Created detailed foundation and structural layouts supported by accurate BOQs for all civil work.

- Miscellaneous Systems: Engineered HVAC systems for optimal climate control and designed fire protection systems in line with safety standards.

- As-Built Documentation: Provided complete as-built documentation, capturing all updates and changes for reliable future reference.

Our detailed engineering services team applied a multidisciplinary approach to crude distillation unit detailed engineering that ensured seamless integration, compliance with standards, and operational excellence, positioning the CDU unit as a pivotal component of the refinery’s expansion.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

inquiries@rishabheng.com

Our Offices

USA, UK & India (Head office)