Project Information

Detailed Design and Engineering of Glycol Regeneration Skid

Description

Client

A US-based project engineering company offering turn-key services from design to installation starting from raw material, fabrication, erection, operation and maintenance.

Engineering Requirement

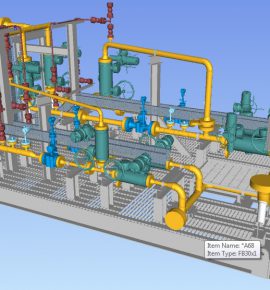

As a trusted skid design services partner, Rishabh Engineering was appointed to execute detailed engineering and design for a Glycol Circulation skid.

The overall scope for this project included;

- Intelligent 3D Model

- Extraction & Submission of Detailed Fabrication Drawings

- BOM

Delivered

Piping:

- Stress Analysis Report including Restraint loads summary, Stress Summary (Sustain stress, Occasional stress, Expansion stress) and Displacement summary

- Flange leakage Analysis Report

- Trunnion or Dummy Support calculation Report

- Final stress isometric Mark-up

- Nozzle Loads qualification sheet

Mechanical:

- Tank and Filter Design Report

- Tank and Filter General Arrangement Drawings

- Tank and Filter Fabrication Drawings with Bill of Material

Structural Analysis

- Structural Analysis & Calculation Report (In-place analysis, Lifting analysis, Transit analysis)

- Anchor bolt layout & foundation load data drawings

- Transportation arrangement drawing

- Lifting arrangement drawing

- Fabrication Drawings

- Structural Bill of Materials

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent blogs

In this blog, we’ll discuss the specifics of coal gasification plant design, including components, considerations, benefits along with potential challenges and how Rishabh Engineering can help solve them with multidiscipline design engineering.

At Rishabh Engineering, our commitment to engineering excellence continues to deliver results. We’re proud to announce our fifth Hexagon Elite Award win at HxGN LIVE 2025 in Las Vegas, Nevada—recognizing our continued innovation on the global stage.

This blog will explore how multidisciplinary design engineering firms like Rishabh Engineering leverage the full potential of AspenTech tools to tackle modern process engineering challenges with precision, agility, and cross-functional insight.