Piping Engineering

We offer piping design services to EPC, PMC’s Engineering Contractors, and OEM’s Owner/Operators globally. Our design team has a wide experience of designing piping solutions for a variety of complex or simple processes for both onshore & offshore customers. And, using our efficient services that meet international codes and standards, the clients can rest assured of meeting the much-required quality norms on project deliverables.

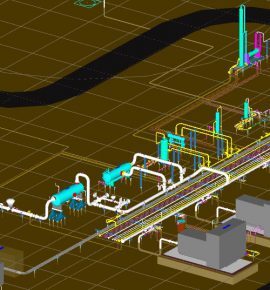

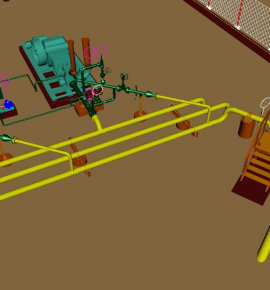

Our team of engineers, designers, and specialists have extensive experience in three-dimensional plant modeling, process equipment design & layout, piping systems design (including air, water, fuel, chemicals, and high-temperature steam) with power and auxiliary system evaluation and improvement. Rishabh’s piping design consultants bring together value from 2D to 3D piping layout, to Pipe Stress Analysis and Studies related to flexibility analysis which, ensures reliability, safety, and simulates the piping system’s worst-case scenarios.

As a process piping engineering and design company, equipped & experienced with various licensed software tools, we have the know-how to solve and avoid challenges through design that a piping system may face. We are always at the forefront to assist with situations that may not be obvious at the outset of the design effort.

Software / Tools/ Technology

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry Codes and Standards adhered to by our Designers

ASME B31.1, B31.3, B31.4, B31.8, B31.11, BS EN 13480, BS EN 14364, Shell DEP

4,80,000

Man-Hours of Project Executed

15 Years

Of Team Experience

ISO 9001 & 27001

Certification

Service Offerings

Rishabh has been providing quality piping engineering services to global clients for over a decade. Our team has the experience and the know-how to assist in the engineering effort through interdisciplinary support. This would include process, mechanical, electrical, structural, and controls.

Our Piping Design Services for any plant facility would Include, 3-D Piping Design, Piping Layout, Piping Supports, Piping Material Selection, Piping Spools, Piping Isometric Drawings, Bill of Material, Material Takeoff (MTO), and Clash Detection. We pay special attention to the layouts & maintenance problems while designing the system. It comprises of placing of control valves, cost-effective pipe routing, optimum pipe size calculations, piping support design, and much more. We help our clients with design outcomes that enable them to construct efficient & resilient plant facilities that sustain a longer project cycle.

Listed below are the focused services offered by our piping engineering consultants:

- Piping DataBase handling & Setup

- Piping 2D/3D route modeling

- Performing piping analysis studies

- Preliminary piping layout, including nozzle orientation

- Preparation of preliminary & detailed GADs, BOMs/MTOs, etc.

- Expansion of piping material specifications (PMS)

- Preparation & Construction of line list according to P&ID

- Preparation of isometrics

- Final GADs/BOM

- IFC isometrics

- Identification & Preparation of critical line list from the piping system design line list according to design standard

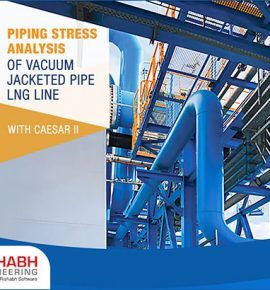

- Modeling in software such as CAESAR II and AutoPIPE form isometrics

- Prepare stress isometrics

- Nozzle datasheets

- Accurate reporting from CAESAR II and AutoPIPE

- Special support preparation

- Preparation of datasheets and requisition for spring hangers, expansion joints, snubbers, slide plates, etc.

- Pipe design & drafting support layouts

- Pipe support detail drawings

- Pipe support markings based on industry standards and special requirements

Ready to Get Started?

What to expect when you work with us

With next-generation tools & technologies, we enable enterprises with top-quality design services that address their core multi-disciplinary requirements.

With the right balance to lead the convergence of digital and physical worlds, we help clients meet their budgets and schedule with varied engagement models. Whatever may be their FTE requirement/project, we can provide a suitable solution.

As a leading piping engineering company, our teams are well versed with working knowledge of international standards like ASME, ASTM, ISO, SAE, ANSI, BS, DIN, and MIL, thereby providing dimensioning and tolerances as per industry standards and applications.

Our teams apply quality processes with process checklists across each project to ensure all drafting errors are mapped across multiple levels of QC and the final design output meets the customer requirements perfectly.

Customers Feedback

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)