Specialized Engineering

Rishabh Engineering provides specialized engineering services such as stress analysis for both greenfield and brownfield designs. Our team is comprised of engineers who are equipped with the expertise to perform stress analyses on new models as well as on existing plans for industries such as oil & gas, refineries, petrochemical & chemicals, renewables, pharmaceuticals, mining, manufacturing, fertilizers, and utility industries such as water and effluent treatment and power.

Software / Tools/ Technology

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry Codes and Standards adhered to by our Designers

AISC, IS, ACI, AASHTO, BS, UBC & API standards, IBC 2012, ASCE 7-10 (Minimum design loads for buildings and other structures), ASME B31.1 (Power Piping), B31.3 (Process Piping), B31.4 (Liquid Transportation), B31.8 (Gas Transmission and Distribution Piping systems)

85,000

Man-Hours of Project Executed

20+ Years

Of Team Experience

ISO 9001 & 27001

Certification

Service Offerings

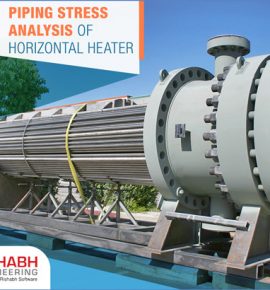

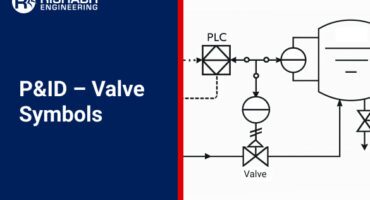

By adhering to industrial engineering codes, we perform stress analyses across the following disciplines:

- It is an essential component of the piping system’s design and engineering.

- It allows engineers to address issues related to the safety of the piping, its components, connected equipment, and piping deflection.

- It prevents the premature failure of the piping and the piping components.

- It ensures the maintenance of the stress in the piping within allowable limits.

- It involves the analysis of loads on the nozzle connecting the equipment to the piping.

- This deals with the design, analysis, and verification of the load-carrying capacities of structural components for pipe racks, pipe supports, structural connections, internal vessel components, rectangular ducts with stiffeners, equipment skids, etc.

- It involves the structural analysis and design of individual structures and non-pressure parts (e.g., platforms, ladders, clips, and other attachments) attached to various parts of the pressure vessels and heat exchangers.

- There are also special types of structural analyses (e.g., fatigue analysis, blast analysis, damage analysis and more), as per client requirements, whereby specifications ought to be carried out.

The process also involves structural design calculations for the estimation of environmental loads (e.g., ice, snow, wind, rain, seismic), equipment, and operating loads.

Ready to Get Started?

What to expect when you work with us

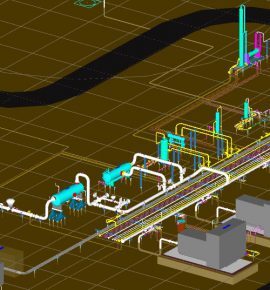

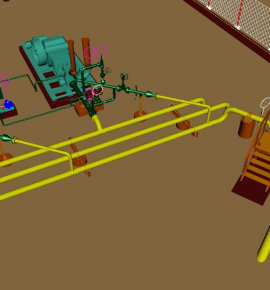

We hands-on experience of leading 3D modeling tools like TEKLA Structures, CADWorx Structures, RISA, SAFE, and SolidWorks. Moreover, we validate or modify them on the structural analysis of steelworks on STAADPro.

By providing the input loads needed for structural calculations, our experienced piping department helps to significantly reduce the project cycle through the quicker implementation of design changes for both steelworks and piping routes.

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

We have expertise in performing stress analysis on new plants as well as existing models for different industries.

CUSTOMERS FEEDBACK

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)