Project Information

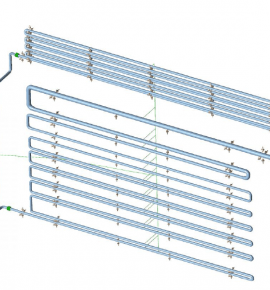

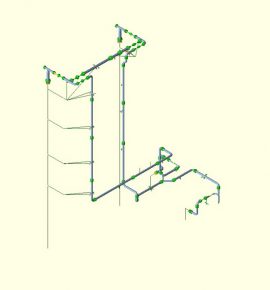

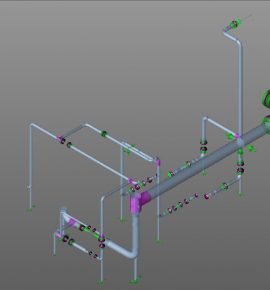

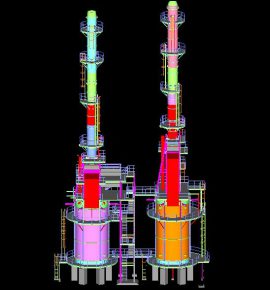

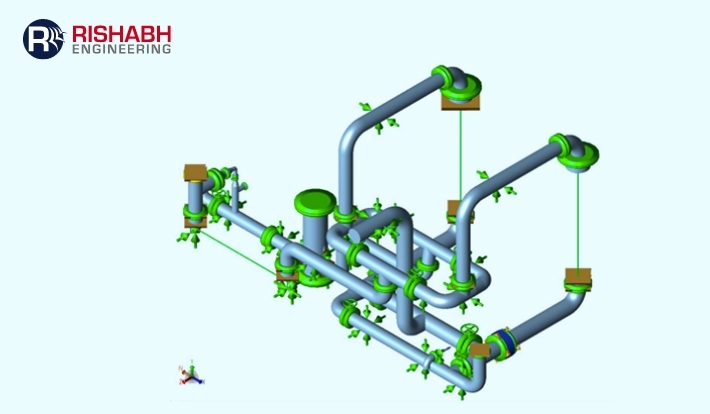

Pipe Stress Analysis of Air Treatment Module Skid Using CAESAR II

Description

Client

A US-based manufacturer of engineered cryogenic gas processing equipment and small-scale process plants for liquefied natural gas (LNG), well services, and industrial gas industries with a significant presence in Southeast Asia.

Engineering Requirement

The client sought recommendations and modifications to meet code requirements and mitigate stress-induced risks. Additionally, they needed insights into tie-in point displacements for seamless integration into their existing infrastructure.

Rishabh Engineering team was engaged to;

- Perform pipe stress analysis & prepare reports/present results as per the provided routing and support type by considering ASME B31.3 design code.

- Provide recommendations with modifications required to qualify the system as per code.

- Sharing Tie-in point displacements.

Our piping stress analysis services team identified 15 critical lines within the Air Treatment Module through meticulous analysis, ensuring a focused approach to stress management. We recommended internal design optimizations to enhance efficiency and performance while ensuring compliance with ASME standards. Volume optimization strategies were also proposed to streamline operations and minimize material and energy wastage, improving overall system effectiveness.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)