Project Information

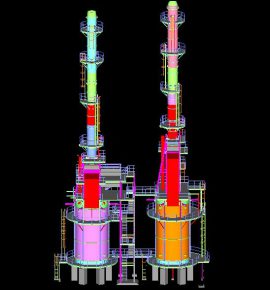

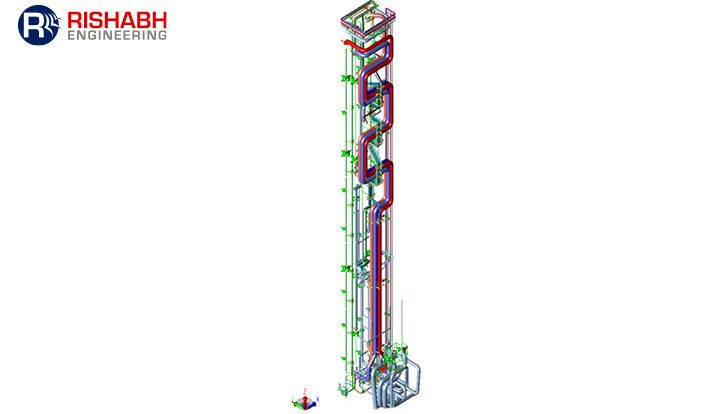

Cold Box Piping Stress Analysis using CAESAR II

Description

Client

A US-based manufacturer of engineered cryogenic gas processing equipment and small-scale process plants for liquefied natural gas (LNG), well services, and industrial gas industries with a significant presence in Southeast Asia.

Engineering Requirement

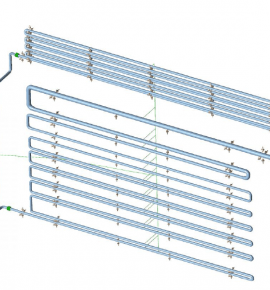

Rishabh Engineering executed cold box piping stress analysis per ASME B31.3 piping code for their MCBM and HECBM Module. With 67 stress critical lines in the new Cold Box, the focus was on ensuring structural integrity and compliance with industry standards.

Our piping stress engineering services scope encompassed:

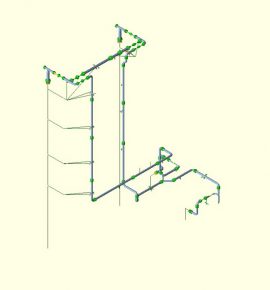

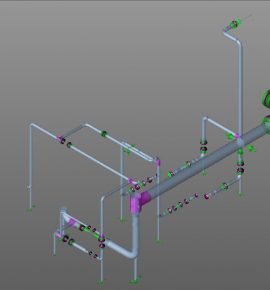

- Conducting stress analysis of cold box piping using Hexagon CAESAR II software.

- Providing recommendations for modifications to meet code compliance.

- Delivering tie-in point displacements analysis.

Utilizing Hexagon CAESAR II software, cold box pipe stress analysis was performed from initially provided isometric drawings. Dassault Systemes eDrawings 2020 x64 Edition facilitated reviews. Given the cryogenic system’s low operating temperature, ensuring flexibility and precise pipeline support positioning was vital.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)