Project Information

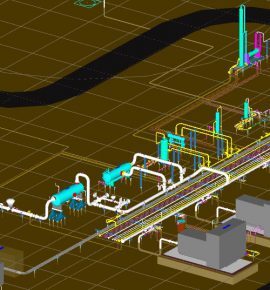

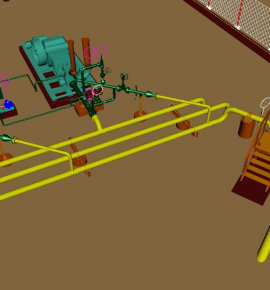

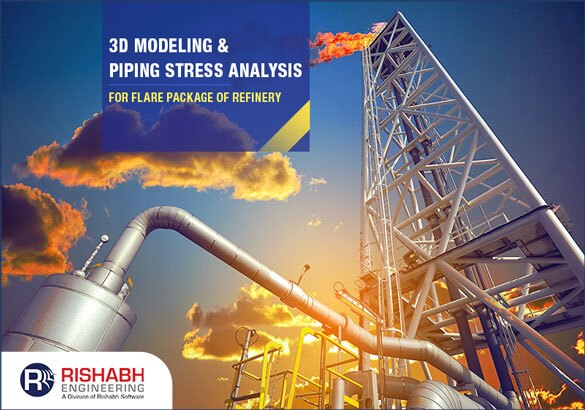

Piping Stress Analysis and 3D Modeling for Flare Package of Refinery with Structural Support Design

Description

Client

A leader in combustion engineering with over 25 years of project package supply expertise, the client provides full design, manufacturing, erection and commissioning services for flare system for oil & gas refinery, petrochemical, fertilizers, steel plants, and allied chemical Industries.

Engineering Requirement

- Develop an intelligent 3D Model using PDMS and Piping Stress Analysis Report (Intergraph CAESAR II) with all the engineering deliverables required for erection & construction with support design

- The scope covered 3D modeling of all major disciplines like piping, mechanical equipment and civil & structural

Delivered

- Final 3D model

- Isometric drawings

- Consolidated Piping – MTO

- Model review files on every fortnight bases for client to review

- CAESAR (.C2)File

- Stress Reports

- Support Drawings

- MTOs

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent Blogs

In this blog, we’ll discuss the specifics of coal gasification plant design, including components, considerations, benefits along with potential challenges and how Rishabh Engineering can help solve them with multidiscipline design engineering.

At Rishabh Engineering, our commitment to engineering excellence continues to deliver results. We’re proud to announce our fifth Hexagon Elite Award win at HxGN LIVE 2025 in Las Vegas, Nevada—recognizing our continued innovation on the global stage.

This blog will explore how multidisciplinary design engineering firms like Rishabh Engineering leverage the full potential of AspenTech tools to tackle modern process engineering challenges with precision, agility, and cross-functional insight.