Project Information

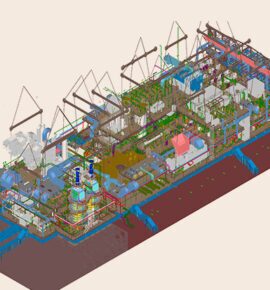

Structural Engineering Support Through Hybrid ODC and DTM model

Description

Client

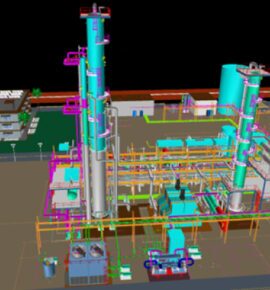

A leading global energy company required advanced structural engineering support to ensure the integrity of its infrastructure during a major expansion project.

Engineering Requirement

Rishabh Engineering provided dedicated structural engineering support under an Offshore Development Center (ODC) model, coupled with on-site placement through a Dedicated Time & Material (DTM) framework. This engagement aimed to address the client’s need for specialized engineering expertise by hiring structural engineers to support their growth in sustainable energy projects, particularly in hydrogen production and gasification technologies.

Project Challenges:

The client faced challenges sourcing specialized talent for large-scale industrial projects due to high competition and evolving industry demands. Key hurdles included rapid resource scalability, hire experienced structural engineers, and training them to align with internal processes and safety standards.

Rishabh’s Approach

- Strategic Requirement Analysis: Conducted a detailed assessment of project scope and identified critical skill gaps across structural, civil, and multidisciplinary areas.

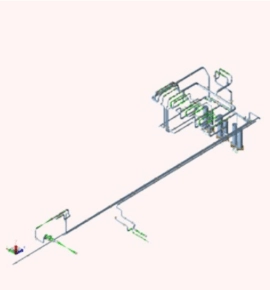

- Targeted Recruitment: Leveraged Rishabh’s extensive network to hire over 20 structural engineers, focusing on competencies in structural, mechanical, piping engineering, and project management. The structural engineer hiring process included talent mapping and salary benchmarking to align with project budgets.

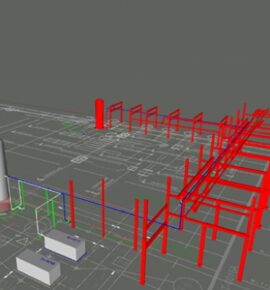

- Structured Onboarding & Training: Implemented a training program led by senior engineers to familiarize recruits with client-specific design standards, operational procedures, and safety protocols. Training emphasized tools like STAAD.Pro, NavisWorks, and AutoCAD.

- ODC & On-Site Integration: Deployed a hybrid support model—offshore teams managed design calculations and CAD modeling, while on-site engineers collaborated directly with client teams to ensure seamless communication and execution.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)