Project Information

Gas Pipeline Project HAZOP and SIL Study

Description

Client

West Africa’s third-largest cement manufacturer enhances operational efficiency and sustainability by transitioning to lean gas fuel.

Engineering Requirement

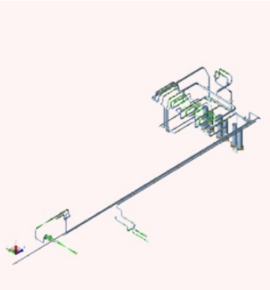

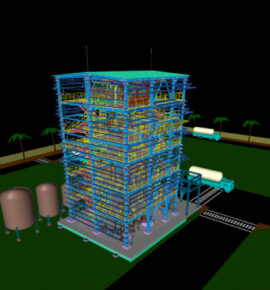

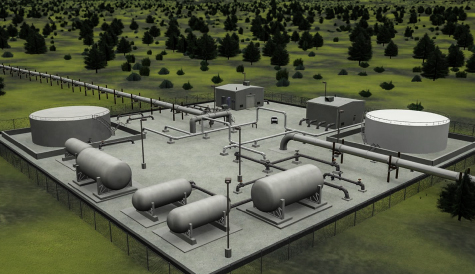

The project involves constructing an 8-inch diameter lean gas pipeline spanning approximately 4.0 km to support the energy needs of a cement manufacturing plant in West Africa. This pipeline is a key component of the local gas distribution master plan, which aims to enhance the delivery of natural gas to critical industrial users. The project demands rigorous safety and operational assessments to ensure seamless integration with existing infrastructure and provisions for future expansion.

1. Pipeline Construction and Design Requirements

- Pipeline Specifications: Design an 8-inch diameter lean gas pipeline spanning 4.0 km from the Pressure Regulating and Metering (PRM) facility to the distribution station.

- Pressure Requirements: Ensure the pipeline operates within a delivery pressure range of 8-10 barg to meet operational demands.

- Materials and Procurement: Identify and acquire materials that meet industry standards for gas pipeline construction, ensuring procurement aligns with project timelines.

2. Safety and Risk Assessment

- Safety Integrity Level (SIL) Study: Conduct a thorough SIL study to determine the necessary safety measures to mitigate potential system failures.

- Hazard and Operability (HAZOP) Study: Perform a HAZOP study to identify and address operational risks and hazards during the pipeline’s construction and operational phases.

3. Regulatory Compliance

- Industry Standards: Ensure all engineering activities comply with relevant international and local safety standards and regulations.

- Local Regulations: Adhere to local government regulations in West Africa for gas pipeline infrastructure projects, ensuring all environmental and operational guidelines are met.

4. Integration with Existing Infrastructure

- Seamless Integration: Plan to integrate the new pipeline with the existing gas infrastructure, ensuring compatibility with current systems while maintaining provisions for future scalability.

- Operational Efficiency: Design pipeline systems that optimize gas delivery to the cement plant, minimizing operational disruptions during installation and commissioning.

5. Project Phasing and Timelines

- Phased Execution: Outline a multi-phase execution plan, starting with detailed design and risk assessments, followed by procurement, construction, and final commissioning of the pipeline system.

- Duration: Manage ongoing project phases efficiently to ensure timely completion and alignment with the client’s infrastructure development goals.

This engineering requirement captures the key technical and safety aspects, ensuring the project aligns with operational, safety, and regulatory standards. Explore how our pipeline engineering team excels in the first phase of conducting detailed engineering for lean gas pipelines, ensuring efficient delivery, safety, and sustainability throughout every project phase.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

inquiries@rishabheng.com

Our Offices

USA, UK & India (Head office)