Project Information

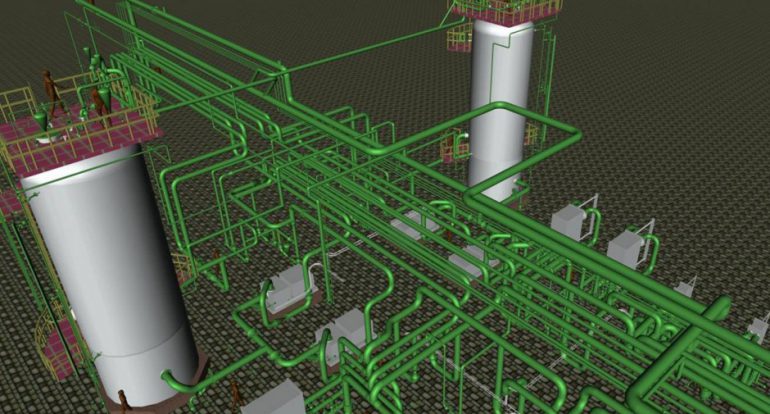

Piping detail engineering for the facility of moisture control and de-hazing of gas oil of the Mina Abdullah Refinery including complete project setup, administration & customization.

Description

Client

The client is an engineering consultancy company, promoted by Paramount Limited – an EPC company, and has been serving the chemical process industry since 1960. It supplies turnkey effluent treatment and water treatment plants having a very large satisfied customers’ base.

Engineering Requirement

This particular project was for the facility of moisture control and de-hazing of gas oil of the MAB refinery where the team had to set up the complete project, its administration and customization of specifications.

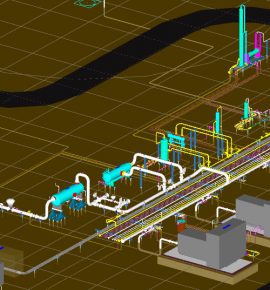

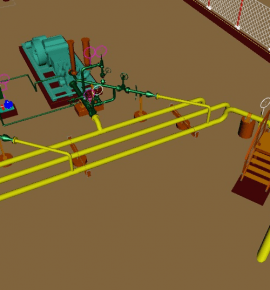

- 3D Modeling of equipment, piping, pipe rack, structures & electrical cable trays

- Marking of supports

- Extraction of Isometric drawings

- Preparation of MTO (Material Take-Off)

- Preparation of GA (General Arrangement) drawings

Delivered

- 3D Model

- Stress Isometrics

- Fabrication Isometric Drawings

- System Isometrics

- MTO – Material Take-off

- GA – General Arrangement Drawings

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)