Project Information

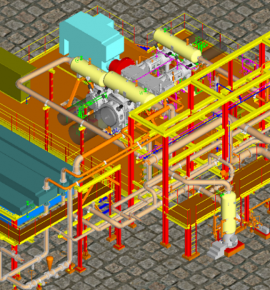

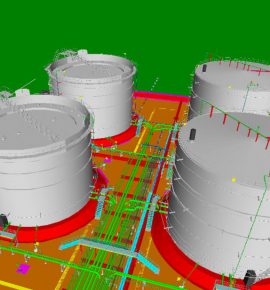

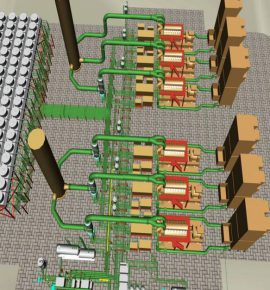

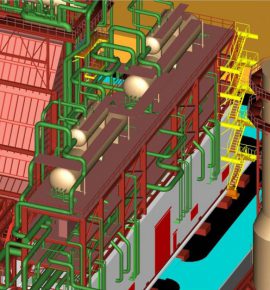

Piping Detailed Engineering & 3D Modeling for a Lube Oil Re-refining Plant

Description

Client

A UAE based multinational with a focus on EPC, Refining, Mining & Trading Construction across five continents with the management of Oil & Gas Installations, Mining, Refining, Trading, Downstream, Midstream, and Upstream.

Engineering Requirement

Rishabh Engineering was appointed as an engineering services partner to conduct piping detailed engineering & 3d modeling using PDMS for the used lube oil re-refining plant in Jeddah- KSA. We were responsible for the following:

- Updating PDMS Library

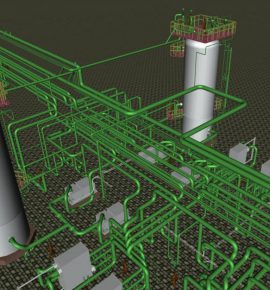

- Piping Design and Modelling in PDMS application

- Modeling of Package Structure, Pipe Rack, Platform, Pipe supports and Vessel trims in PDMS application

- Preparation of Drawings for Nozzle Orientation

- Periodic 3D Model Review ( 30%, 60% & 90% Model Review/Report) and request for approval

- Extraction of Piping GA drawings, Isometrics with complete BOM & Support type

- Preparing Special Support Drawings with complete BOM

- Extraction of Piping & Valve MTO

- Modeling

- Instruments, Junction boxes with supports as per input

- Electrical & Instrumentation Cable trays as per the shared information

- Electrical JBs and DBs, Column or wall-mounted electrical supplies, Earthing / Lighting pit location as per customer’s data

- Electrical & Instrumentation structural supports as per the provided information

- Civil foundation and Pipe rack structures, roads pavements, pits, culverts

- Structures like MCC Building and Control room building, Utility building

- Preparation of PMS and Material Requisition

- Insulation specification

- Painting specification

- Wrapping and coating specification

Delivered

- Piping Stress Analysis Report

- 3D Models

- Piping Support Material Take off (MTO)

- Pipe Support List

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent blogs

In this blog, we’ll discuss the specifics of coal gasification plant design, including components, considerations, benefits along with potential challenges and how Rishabh Engineering can help solve them with multidiscipline design engineering.

At Rishabh Engineering, our commitment to engineering excellence continues to deliver results. We’re proud to announce our fifth Hexagon Elite Award win at HxGN LIVE 2025 in Las Vegas, Nevada—recognizing our continued innovation on the global stage.

This blog will explore how multidisciplinary design engineering firms like Rishabh Engineering leverage the full potential of AspenTech tools to tackle modern process engineering challenges with precision, agility, and cross-functional insight.