Validate thermal design of dry expansion heat exchanger for North American client specializing in cryogenic gas processing and LNG solutions.

Thermal Design of Dry Expansion Type Heat Exchanger

Client

US-based Cryogenic Technology Leader

Category

Manufacturing

Location

North America

Project Duration

2 Weeks

Software Tools

Engineering Requirement

Chilling Plant requires an effective air-cooling system and for that Dry Expansion (DX) type of shell and tube heat exchanger plays a pivotal role. Our experienced equipment engineering services team was commissioned to validate the dry expansion heat exchanger thermal design, conduct thermal rating assessments, and optimize both internal design and volume considerations for the heat exchanger. Their objective was to ensure optimal heat exchange between refrigerant R134a and Saturated Air, fostering efficient air cooling while minimizing energy consumption.

Harnessing the capabilities of AspenTech’s Exchanger Design & Rating (EDR)™, Rishabh Pro Engineering worked on dry expansion evaporator thermal design.

Project Deliverables

Detailed review of existing design strengths and improvement areas.

Validation of thermal ratings.

Recommendations for internal design enhancements.

Strategies for volume optimization.

Thermal design and rating analysis using AspenTech Exchanger Design & Rating (EDR)™.

Verification of NEU TEMA-type adherence. Performance Recommendations

Suggestions for achieving superior heat transfer efficiency and energy savings.

The DX-Type Shell and Tube Heat Exchanger:

Characterized by its NEU TEMA-type configuration, the DX-type Shell and Tube Heat Exchanger was the cornerstone for facilitating dry-type evaporator thermal design between refrigerant R134a and Saturated Air within the Chilling Plant. The primary aim was to achieve superior heat transfer efficiency while minimizing energy consumption, thereby optimizing operational costs.

Want to know more about this project?

Projects Showcase

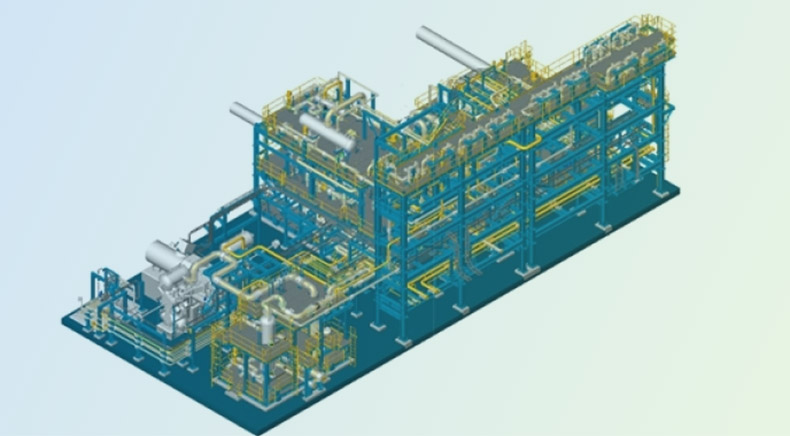

Multi-Skid Modular Package Detailed Engineering for Process Plant

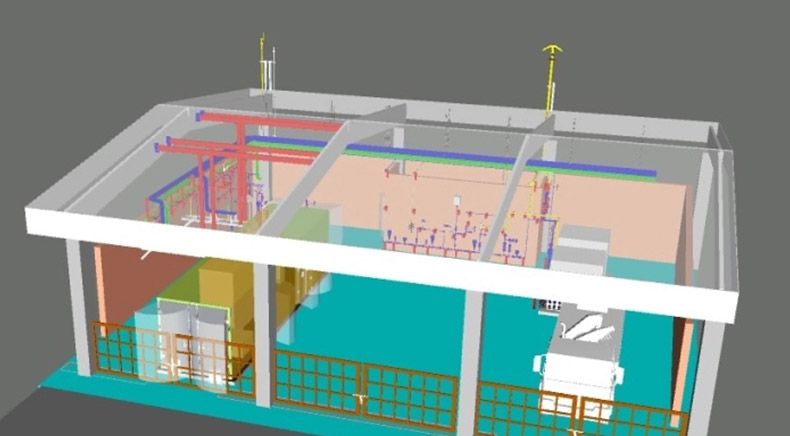

Design & Engineering Integration With Balance of Plant for a Green Hydrogen Project

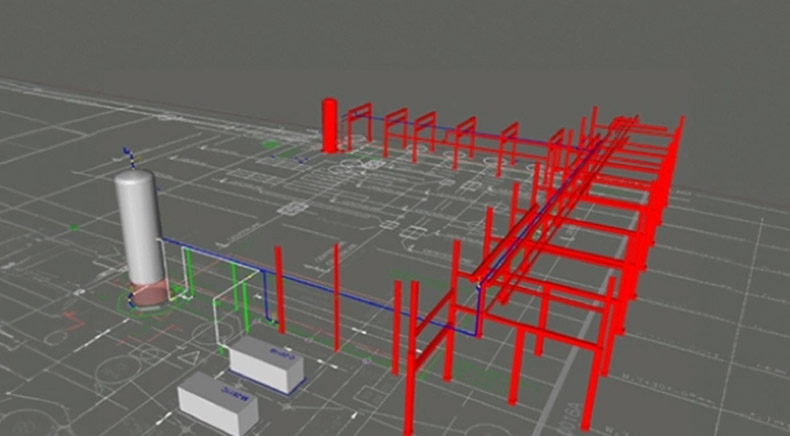

Pre-Bid Support for Engineering of Natural Gas Compressors System

Structural Engineering Support Through ODC & On-Site Placement

Detail Engineering & Design Activity for Fired Heater

HAZOP & SIL Study For The Ghana Gas Pipeline Project

FEED & Detailed Engineering Support Services For Instrument Air Package

Extended Basic & Detailed Engineering Of 20K BPD CDU Unit Refinery

Detail Engineering & Procurement Support for Gas Pipeline Project

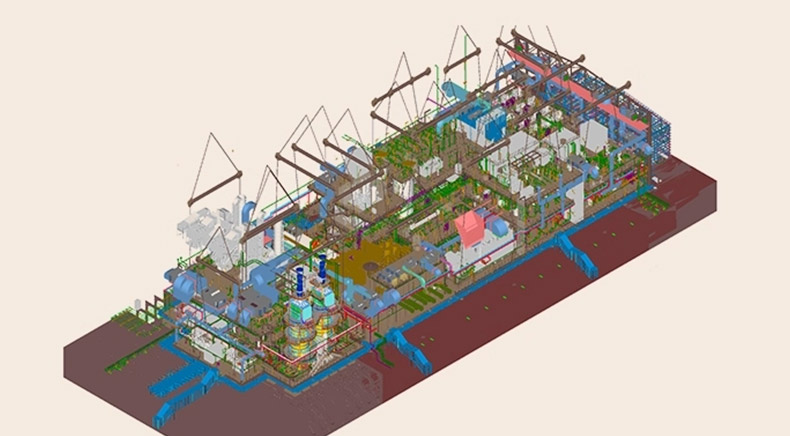

Piping Stress And Flexibility Analysis of P79 Buzios 8 FPSO Module

Looking for a Reliable Design Engineering Partner?

We’re ready to collaborate. Get in touch to discuss how Rishabh Pro Engineering can support your next project.