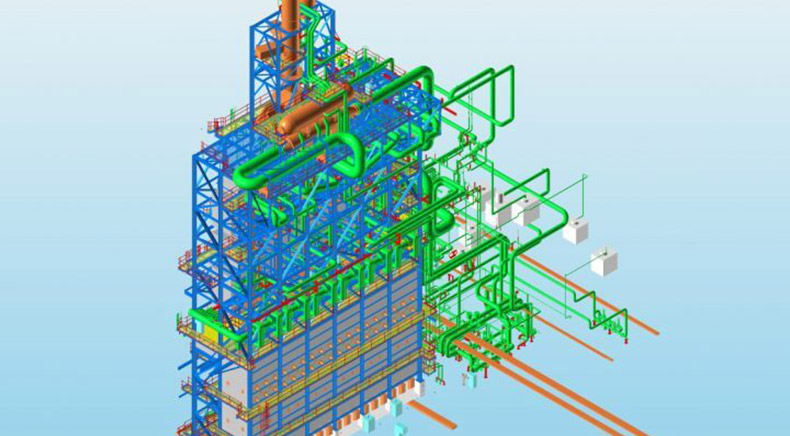

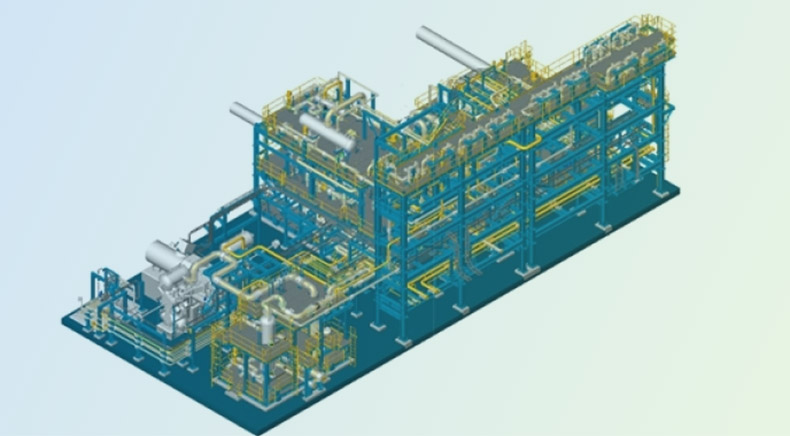

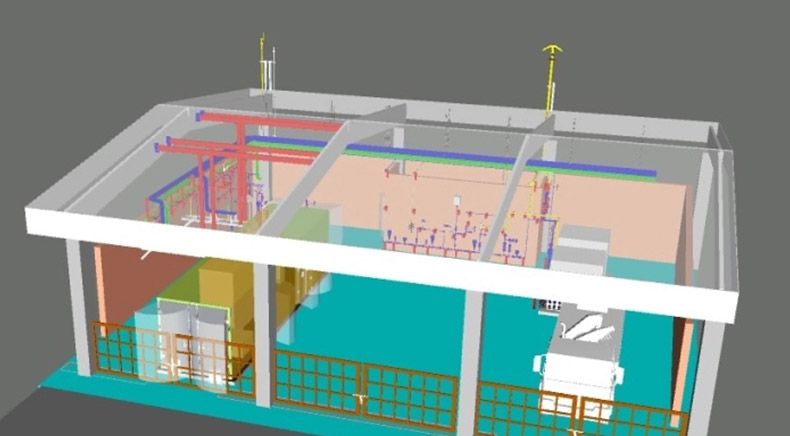

Ethylene Cracking Unit – 3D Modeling On PDMS

Client

UK-based Chemical Manufacturing Company

Category

Petrochemical

Location

USA

Project Duration

2 Months

Software Tools

Engineering Requirement

- PDMS administration

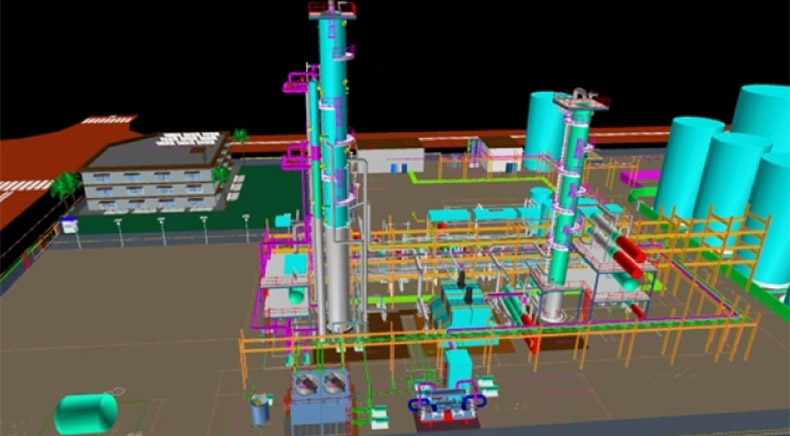

- Equipment modeling – Furnace & 10 equipment

- Modeling of equipment foundations / Structural platforms / Ladders / Manholes / Envelopes

- Piping designing and modeling in PDMS

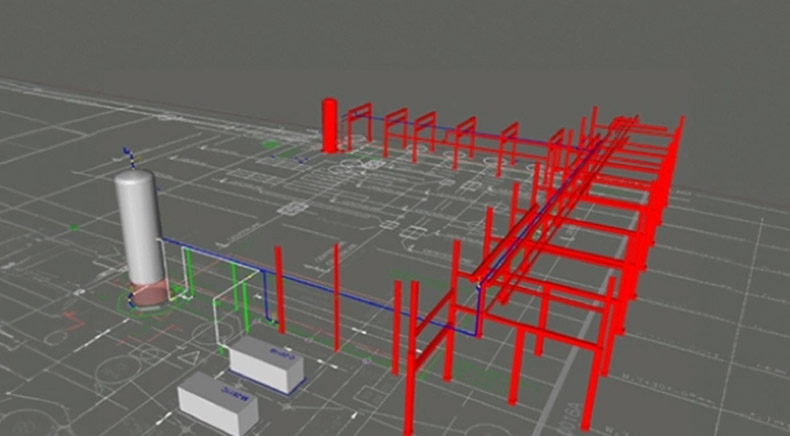

- Structural modeling

- Physical support modeling

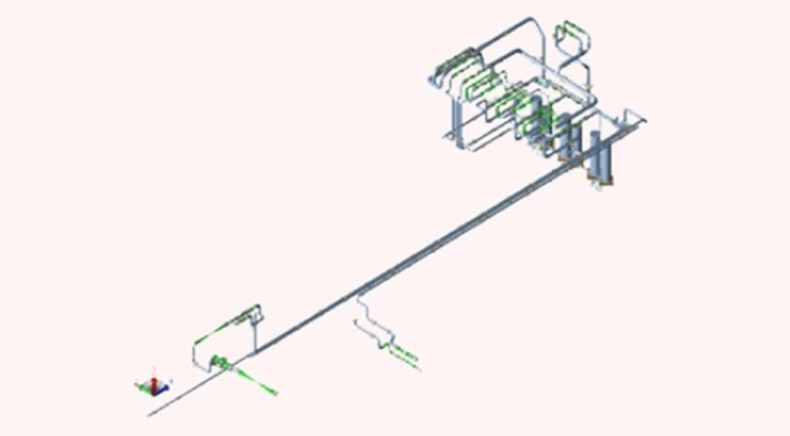

- Modeling of E&I cable trays

- Modeling of instruments and electrical equipment’s

Project Deliverables

3D Model at different stage for review (30%, 60% & 90%)

Final 3D Model

Sample Isometrics and Gas

Want to know more about this project?

Projects Showcase

Multi-Skid Modular Package Detailed Engineering for Process Plant

Design & Engineering Integration With Balance of Plant for a Green Hydrogen Project

Pre-Bid Support for Engineering of Natural Gas Compressors System

Structural Engineering Support Through ODC & On-Site Placement

Detail Engineering & Design Activity for Fired Heater

FEED & Detailed Engineering Support Services For Instrument Air Package

Extended Basic & Detailed Engineering Of 20K BPD CDU Unit Refinery

Detail Engineering & Procurement Support for Gas Pipeline Project

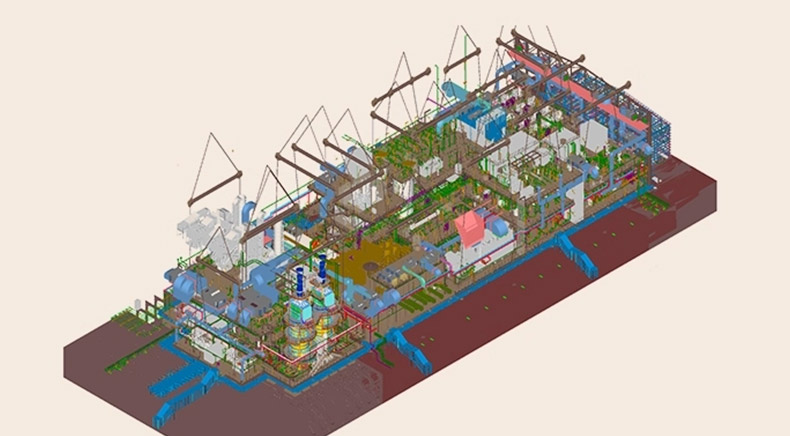

Piping Stress And Flexibility Analysis of P79 Buzios 8 FPSO Module

Industrial Caster Exhaust System Design, Engineering and Cost Estimation

Looking for a Reliable Design Engineering Partner?

We’re ready to collaborate. Get in touch to discuss how Rishabh Pro Engineering can support your next project.