Project Information

Industrial Exhaust System Design and Engineering

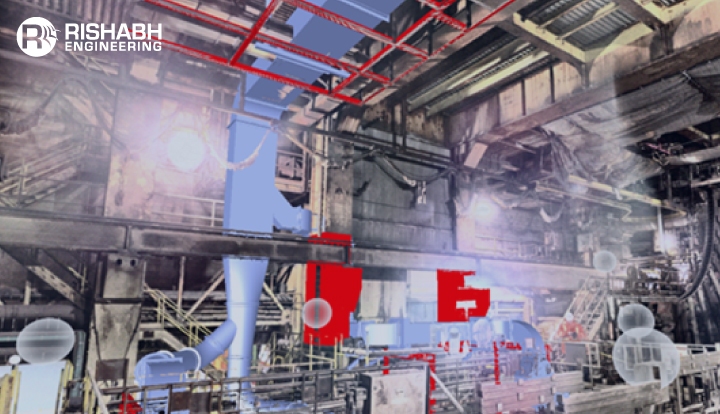

Description

Client

A US-based process engineering services company specializing in air pollution control & energy optimization for the metals processing industry worldwide.

Engineering Requirement

The client’s steel shaping Caster faces steam overload issues, impacting operations and safety. They seek to advance improvement by finalizing the system design and layout, with the Rishabh Engineering team supporting them with industrial exhaust systems design and engineering across phases.

The scope of this industrial ventilation system design and engineering project includes the following key engineering activities:

Review/Access Point Cloud Data:

Provide scanning recommendations to ensure accurate data collection of existing conditions.

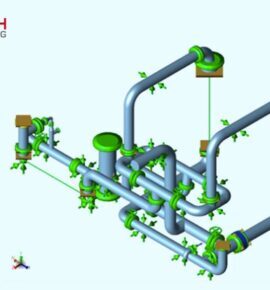

Process Engineering:

Mark-up Piping and Instrumentation Diagrams (P&IDs) based on piping and instrumentation design.

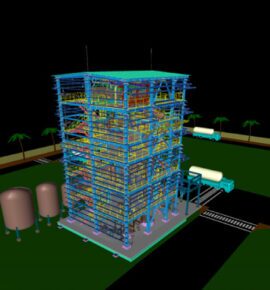

Mechanical Engineering:

- Develop a basic-level, non-intelligent 3D model for major equipment layout.

- Design ductwork routing and cover off-takes.

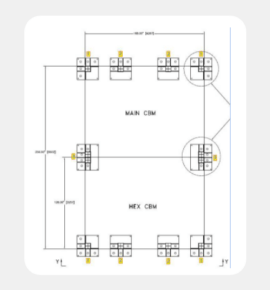

- Generate General Arrangement Drawings (GAD) from the 3D model.

Civil & Structural Engineering:

- Perform structural analysis of the existing system to evaluate member sizes for new loads.

- Develop civil foundation designs for ductwork support towers, fans, and stacks.

- Create a preliminary civil/structural fabrication package.

- Prepare Material Take-Offs (MTOs) based on the final layout and support configuration.

Electrical & Instrumentation Engineering:

- Develop requirements for new equipment, such as Induced Draft (I.D.) fans.

- Establish electrical load lists.

- Create Single Line Diagrams (SLDs).

- Develop preliminary instrument lists and Input/Output (I/O) lists.

Cost Estimation:

Provide detailed cost estimates based on finalized layouts and engineering specifications.

The industrial ventilation design and engineering project aims to resolve steam overload issues in the Caster area, enhancing operational efficiency, equipment integrity, and safety. Our detailed engineering services team offered comprehensive engineering design & support to ensure a smooth transition from basic to detailed engineering, leading to the successful implementation of an optimized steam exhaust system. This helped improve performance and safety in the client’s steel shaping process, ultimately supporting their broader production goals.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)