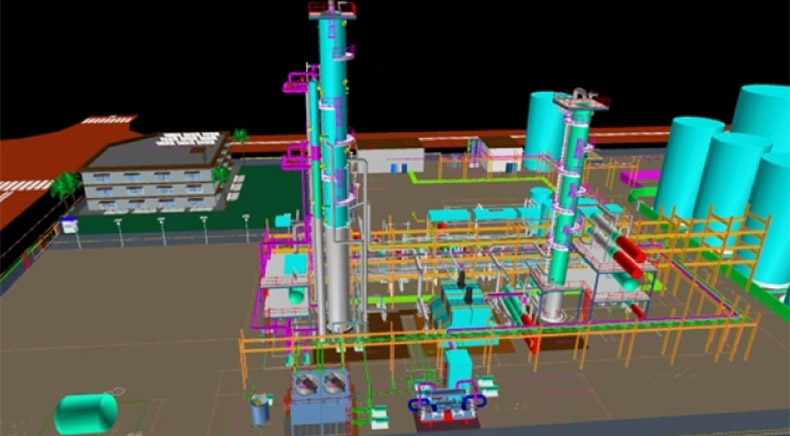

Multidiscipline Engineering for Reactor Area of Acetylenics Complex Plant

Client

US-based EPC Company

Category

Petrochemical

Location

USA

Project Duration

3 Months

Software Tools

Engineering Requirement

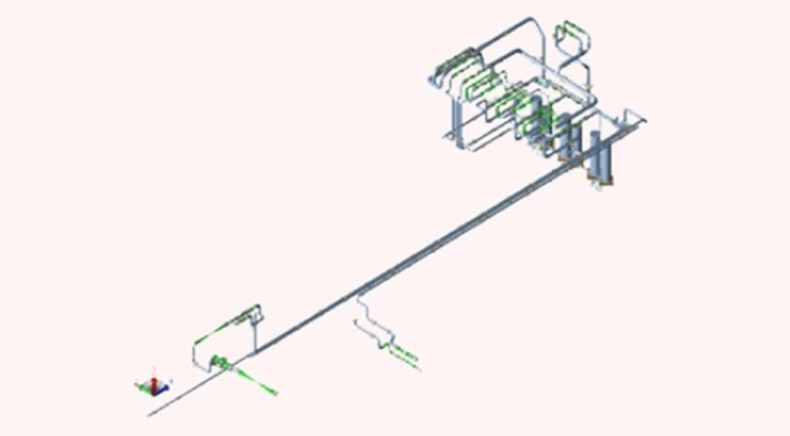

- Multidiscipline engineering for the reactor area of ACE (Acetylenics Complex) plant including civil & structural engineering, pipe stress analysis, electrical & instrumentation and piping engineering

- Plant’s direct steam injectors to be replaced with 4 shell and tube heat exchangers

Project Deliverables

Equipment GA Drawings

Visual Stress Analysis reports

Equipment Foundation Drawings

Special Support drawings

3D Model on PDS

Instrument Datasheets

Isometrics Drawings

I.E. ASME B31.3 codes and standards were followed to ensure high quality of delivery

Technical Bid Evaluations (TBE) for vendor equipment selection

Want to know more about this project?

Projects Showcase

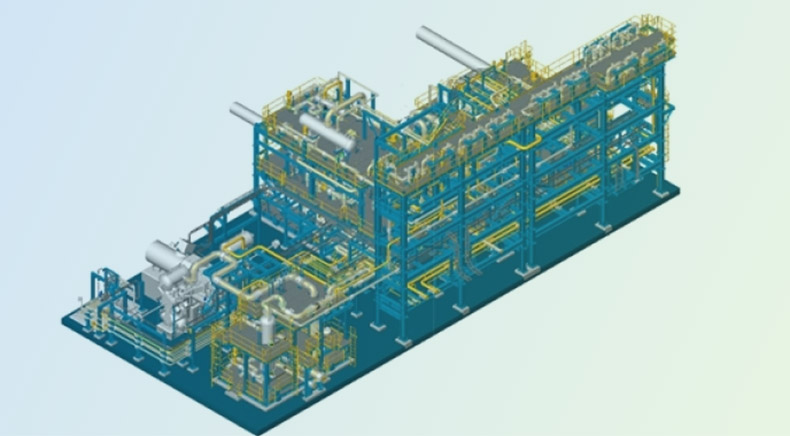

Multi-Skid Modular Package Detailed Engineering for Process Plant

Design & Engineering Integration With Balance of Plant for a Green Hydrogen Project

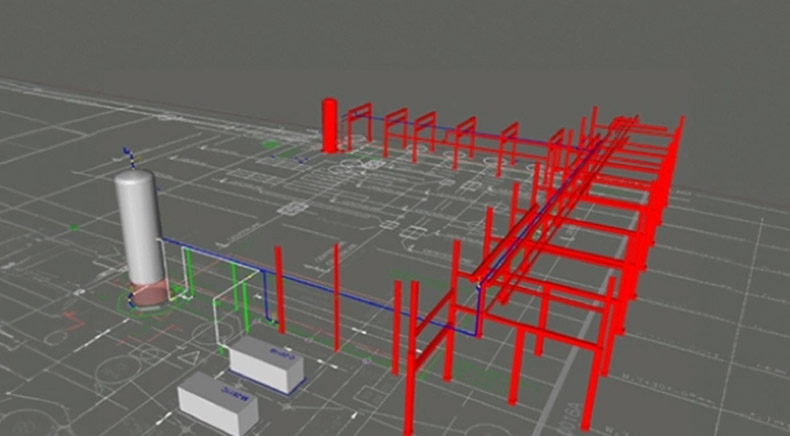

Pre-Bid Support for Engineering of Natural Gas Compressors System

Structural Engineering Support Through ODC & On-Site Placement

Detail Engineering & Design Activity for Fired Heater

HAZOP & SIL Study For The Ghana Gas Pipeline Project

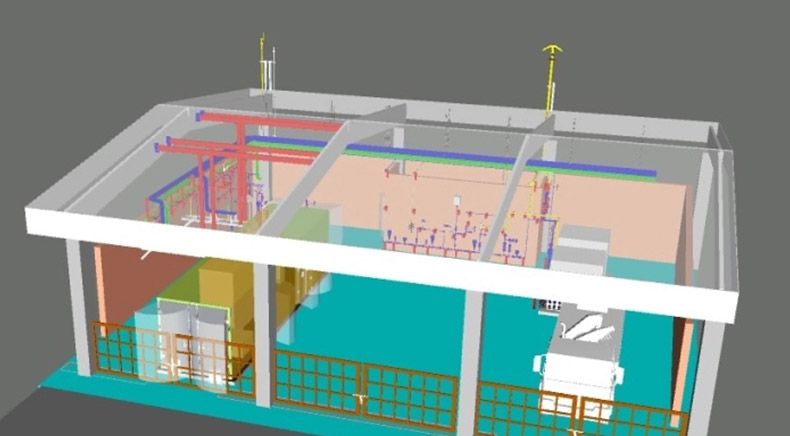

FEED & Detailed Engineering Support Services For Instrument Air Package

Extended Basic & Detailed Engineering Of 20K BPD CDU Unit Refinery

Detail Engineering & Procurement Support for Gas Pipeline Project

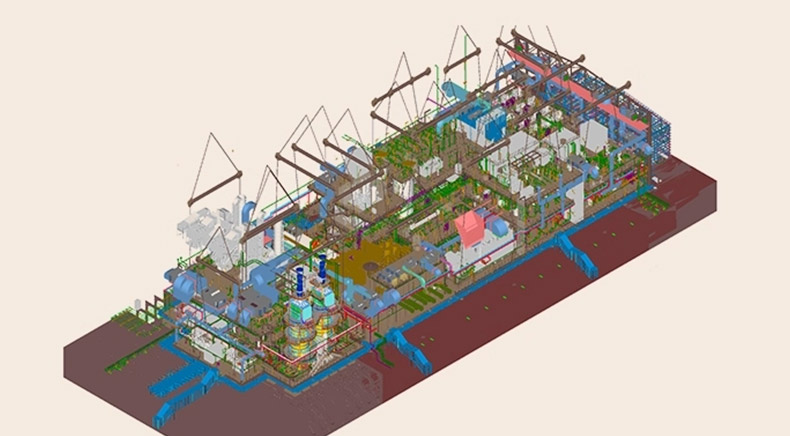

Piping Stress And Flexibility Analysis of P79 Buzios 8 FPSO Module

Looking for a Reliable Design Engineering Partner?

We’re ready to collaborate. Get in touch to discuss how Rishabh Pro Engineering can support your next project.