Pipe Stress Analysis Using CAESAR II Software

CAESAR II is a leading software that assists engineers in determining the strength of pipes. They use it to build and test pipelines for various sectors, including oil, gas, and power generation. It’s manufactured by Hexagon PPM, formerly known as COADE, Inc. CAESAR II has been used by engineers for many years and is extremely useful in building and engineering operations. This post will look at Rishabh Engineering’s capability of conducting pipe stress analysis using CAESAR II, software’s major features with real life case studies, and more.

How Does The Rishabh Engineering Team Utilize Hexagon’s CAESAR II?

Our team uses Hexagon’s CAESAR II software to ensure piping systems’ structural integrity and safety across various sectors. This program facilitates in-depth stress analysis and evaluation of piping system efficiency under various operating circumstances. This would entail evaluating pressure, temperature, fluid flow, and structural stresses to identify potential problems such as excessive stress, vibration, or displacement. During the project design phase, it aids in recording comprehensive piping system specifications, such as dimensions, materials, and operational characteristics, in the program. Furthermore, our team analyzes how the pipes would behave in various scenarios, allowing us to optimize the design for optimum efficiency and reliability while minimizing hazards.

Furthermore, during the construction phase, it assists the team in validating piping system installation while assuring compliance with industry norms and laws. As a result, by running simulations under real-world situations, they can ensure that the installed pipework can handle the strains encountered during operation. Furthermore, CAESAR II can help troubleshoot and resolve difficulties with existing piping systems. If problems happen, such as leaks, excessive vibrations, or unexpected failures, the team uses this program to identify the underlying reasons and build effective solutions. This proactive strategy reduces downtime and maintenance costs while improving overall system performance and safety. The Rishabh Engineering team conducts pipe stress analysis with CAESAR II, which is a valuable tool for designing, assessing, and optimizing pipe systems. Rishabh Engineering is a four-time “Drivers of Success” award winner, delivering impressive results for the end customers using CAESAR II.

About CAESAR II - Introduction

CAESAR II® is the industry standard for pipe stress analysis from Hexagon. It allows you to design, evaluate, and report on piping systems of any size or complexity in conformity with over 35 international piping code standards and numerous environmental and equipment requirements. Integration with CAD design tools allows you to import models rapidly, decreasing the possibility of errors and costly iteration time between the CAD and Stress Analysis divisions. Historically, COADE, Inc., a Texas company, started making CAESAR II in the late 1980s. It has improved over the years, especially for checking how pipes can handle stress. In 2005, another big company called Hexagon AB bought COADE. They’ve kept improving the software, and now it’s called Hexagon PPM.

Benefits Of Pipe Stress Analysis with CAESAR II

- Leading 3D Graphics

- Robust Load Case Definitions

- Advanced Reporting

- Finite Element Analysis

- Powerful Integration Capabilities

- Comprehensive Equipment Analysis

- Nuclear Industry Compliance

Key Features of CAESAR II

CAESAR Software for pipe stress analysis is renowned for its robust feature set, which includes:

Structural Modeling

Advantage:

- To transfer vessel load on the structure

- To qualify the system in stresses & nozzle qualification against allowable for its actual effect

Isometric Extraction

Advantage: Enables;

- Routing change markup for stress recommendation for the layout team

- Selecting support from marked-up support gaps with support type

Importing PCF Files

Advantage:

- Helps to reduce the modeling efforts by using the “Advance pcf” option

- Reduces modeling errors and efforts

Spring Can with Friction Builder

Advantage:

- Considers friction to be included in the analysis

- The builder automatically aligns if the pipe is skewed

Using Excel Sheet for CAESAR II Input Checking

Advantage:

- Used for input quality checks

- Man-hours optimizations

Load cases import from MS Excel

Advantage:

- Very good graphics, More features for Steel & Civil

Fluid Density Multiplier in Static Load Case Editor

Advantage:

- Enables adjusting static load cases by using a Fluid Density Multiplier (FDM) if there’s a change in fluid density since total weight is important for a piping system

COG Report Generator

Advantage:

- Used for Lifting & Transportation analysis

- Used for Foundation Design

Integration with Other Software

Advantage:

- Offers Time & Cost savings

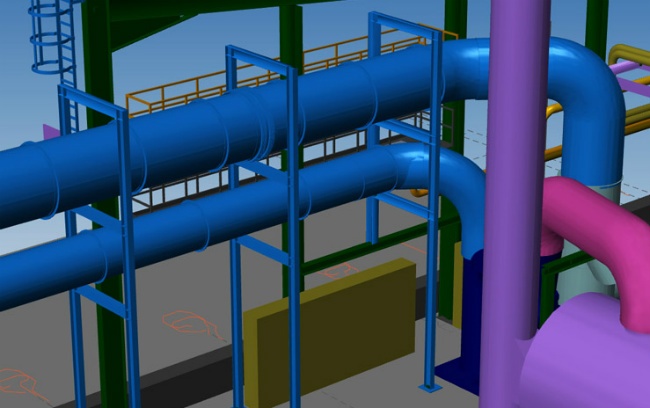

Smart 3D Integration – Deflected Pipe Interference Detection

Advantage:

- Significant cost savings as well as improving operational safety and reducing overall risk

Piping stress analysis with FEA Program

Advantage:

- Access tools for finite element analysis and use ASME B31J-2017 calculations for SIFs and K factors

- Time & Cost savings

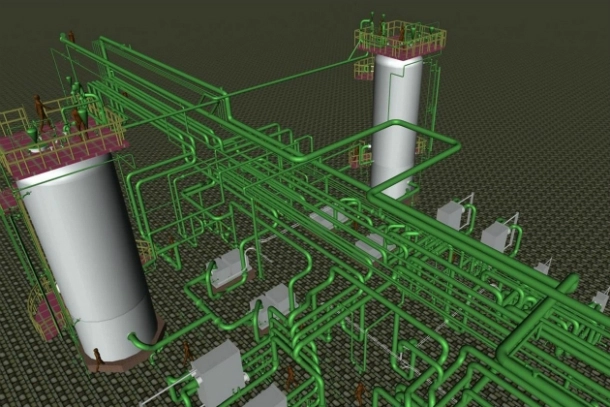

Integration with Other 3D Modeling Software – Vue file

Advantage:

- Helps to reduce errors & efforts

- Easily available reference for CII file. Overlapping of CII & .Vue file makes the system clear with its routing & support types

Codes & Standards

Different standards and criteria govern how pipes are designed and tested; CAESAR II helps enforce several of them. Some crucial ones are:

- ASME B31 Series: These codes, issued by the American Society of Mechanical Engineers, are used to transport pressure in various sectors.

- API Codes: The American Petroleum Institute (API) creates standards for the oil and gas industry.

- ISO Standards: These codes, established by the International Organization for Standardization, are widely used worldwide.

- EN Codes: European Norm codes for projects/applications in Europe.

- Other Regional Codes: Additional local codes may apply depending on the project’s location.

Further, you can explore how the Rishabh Engineering team helps revolutionize plant engineering by leveraging Hexagon’s software, such as CADWorx, CAESAR II, and more, to transform complex engineering challenges into innovative solutions.

Real Life Use Cases – CAESAR II

Case 1: Piping Stress Analysis For Gas Receiving Station Of A Power Plant Using Hexagon CAESAR II

Project: Piping Stress Analysis of Natural Gas Receiving & Conversing Facility

Client: Large EPC conglomerate

Objective: Utilizing software tools, including Hexagon CAESAR II 2018, AutoCAD 2016, and NavisWorks 2018, our team collaborated with a prominent EPC conglomerate in Greece specializing in various industries. Over 8 weeks, we conducted piping stress analysis for the Power Plant’s Gas receiving station. We developed detailed construction drawings and material take-offs for piping supports at a gas receiving station, meeting the client’s engineering requirements and delivering comprehensive documentation.

Case 2: Pipe Stress Analysis & 3D Modeling of Pressure Vessels using CAESAR II

Project: A Petrochemical plant located in the US region

Client: An engineering services provider engaged in pressure vessels & exchangers, design and analysis of piping components, cyclic services, linear and non-linear structural design & analysis

Objective: Our team conducted pipe stress analysis & 3d modeling of pressure vessels using CAESAR II. The Hexagon software helped optimize data extraction while minimizing loss during file handling using CAESAR II and CADWorx. This approach saved time and prevented errors. They successfully retrieved CAESAR II files from CADWorx, addressing broken links and aligning boundary conditions. Key steps involved: 1) Generating a neutral CADWorx file, 2) Importing into CAESAR II, and 3) Resolving data losses to refine the CAESAR model. As a successful outcome, this project helped achieve a 12% reduction in estimated project time while leveraging the CAESAR II model generated using CADWorx software.

Case 3: Stress Analysis Of Vacuum Jacketed Liquid Nitrogen Pipes Using CAESAR II

Project: Piping Stress Analysis of Vacuum Jacketed Liquid Nitrogen Lines

Client: A North American manufacturer of cryogenic gas equipment and systems.

Objective: Rishabh Engineering undertook the piping stress analysis for Vacuum Jacketed Liquid Nitrogen lines. Activities encompassed stress analysis, weld strength checks, collapse calculations, surge analysis, and snow load considerations. Load conditions like seismic, wind, thermal, pressure, hydro test, and sustained loads were factored in. Weld strength checks were conducted at the core pipe, jacket, and sleeve welding points.

Final Words

CAESAR II is a strong tool, but its effectiveness depends on the engineers’ skill. Engineers are super important because they ensure that pipes are designed, checked, and maintained to keep them safe and working well. It is an important component of modern engineering to ensure pipes are safe and work properly worldwide. As the engineering world keeps changing, CAESAR II will change too, to keep helping engineers ensure pipes stay safe for a long time. Our piping stress analysis services team conducts detailed analysis, evaluation, and confirmation of the structural & operational integrity of process piping systems.

Seek Help with Pipe Stress Analysis?

Our team utilizes CAESAR II to conduct pipe flexibility and stress analysis across varied piping systems.

Related Blogs

Related Blogs

Piping Support Design and Engineering

Pipe support design is an important component of piping engineering…

Detailed Engineering of Piping Systems

Detailed engineering involves design, detail, engineering and layout of piping…