Project Information

Pre-Bid Engineering For Natural Gas Compressors

Description

Client

A major Southeast Asian energy company

Engineering Requirement

A power station in Singapore faced a critical pressure drop in its natural gas supply, risking turbine shutdowns. The client required pre-bid engineering support for natural gas compressor systems for four essential stations (CCP 1 to 4) to ensure uninterrupted gas turbine operations.

Rishabh Engineering provided comprehensive pre-bid engineering support to design and configure compressors while addressing them effectively and delivering a future-ready solution.

Project Scope For Natural Gas Compressors Pre-Bid Engineering:

- Compressor System Modifications: Redesigned existing reciprocating compressors at CCP 1 & 2 to operate in a parallel 2×50% configuration, enhancing gas flow capacity.

- New Screw Compressor Design: Engineered two new screw compressors for CCP 3 & 4, with provisions for future expansions.

- Hydraulic Analysis: Conducted detailed calculations to optimize piping and compressor system performance.

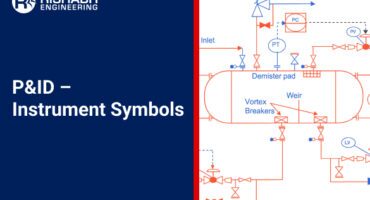

- Updated P&IDs: Integrated new and existing systems seamlessly into the design.

- Procurement Assistance: Prepared RFQs for key components, including compressors, buffer tanks, and air fin coolers.

- Multidisciplinary Layouts: Developed detailed layouts and equipment specifications covering piping, civil, mechanical, electrical, instrumentation, and firefighting systems.

Our pre-bid engineering services helped mitigate risks of pressure drops, ensured uninterrupted gas turbine performance, and provided a scalable system design for future needs. This enabled the client to proceed confidently into the bidding phase with a robust, optimized engineering package while addressing critical operational challenges, reducing risks, and thus preparing for seamless project execution.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)