Project Information

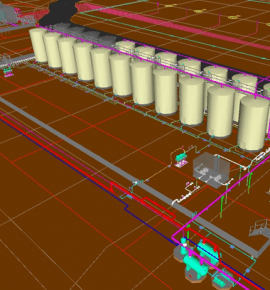

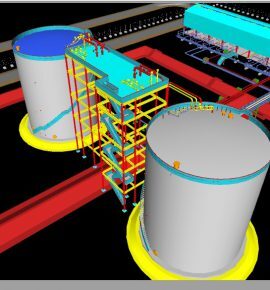

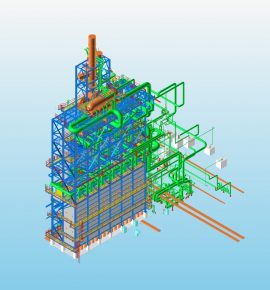

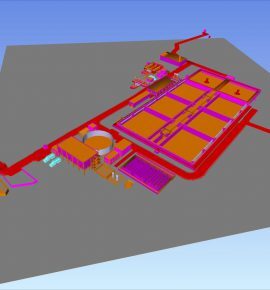

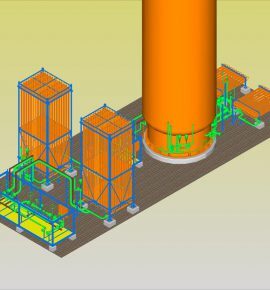

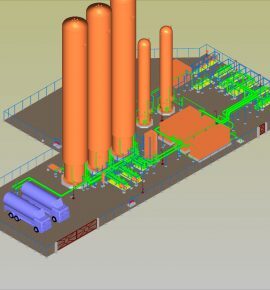

3D Modeling of a Double Stack Industrial Generator Enclosure

Description

Client

US-based industrial manufacturer of Engineered Cooling & Power Packaging Solutions

Engineering Requirement

The client was in the process of standardizing & customizing 3D models, fabrication drawings & another project database of operation & manufacturing data designs to meet the growing demands for advancement in the product line. They were looking for an established engineering support services provider to take up this work and ensure a higher level of data security and highly detailed designs, helping them create a High-Value Engineering Center (HVEC).

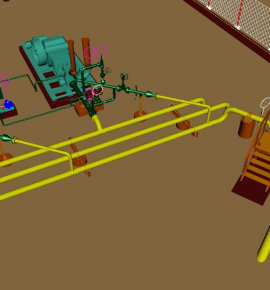

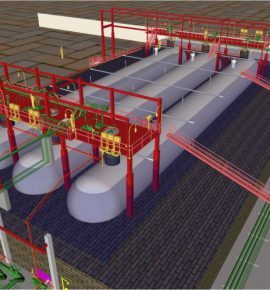

Appointed as their 3D CAD modeling services partner, our job was to create a 3D Model of the Power Generator Enclosure, extract fabrication drawings, and more, including complete detailed fabrication drawings packages. As part of this, our primary challenge was to create engineering drawings based on the initial GA. It included an enclosure that involved HVAC ducting routing inside the completed enclosure. The air cooling requirements, heat exchanger sizing, louver sizes & filter static pressure were to be considered.

Backed by advanced modeling tools and sophisticated software like SOLIDWORKS, we were able to create master 3D drawings. It included

- DG Set installation drawings give complete details of all the equipment’s foundations

- Line diagram and layout of all electrical control/ AMF panels giving switchgear rating and their disposition, cable feeder sizes and their layout

- Control wiring drawings with all control components and sequence of operations to explain the process of control circuits

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)