Project Information

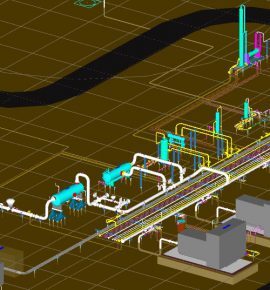

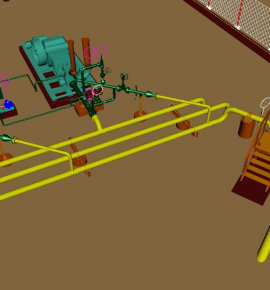

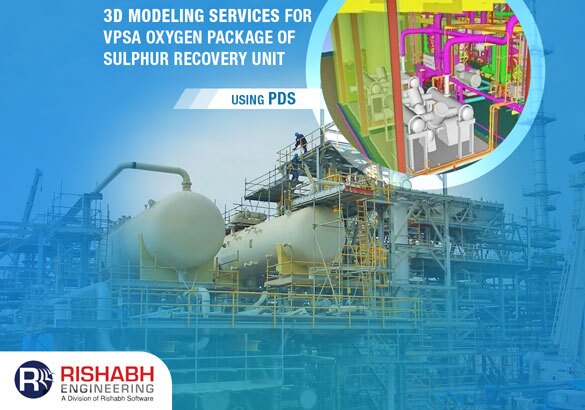

3D Modeling of Vacuum Pressure Swing Adsorption Oxygen Package for Sulphur Recovery Unit

Description

Client

The client is the global supplier of industrial gas plants with associated technical solutions and engineering services. It provides 360o engineering solutions right from conceptual design to EPC services, commissioning & after sales services which meet international quality and safety standards.

Client Testimonial

“The engineering model developed by Rishabh Engineering for our Phase 2 project covering the mechanical construction has received very positive feedback from the client and the construction crew with the quality of the drawing package. It was virtually perfect. I appreciate all the hard work of the team members.”

– President

Engineering Requirement

3D modeling of a VPSA Oxygen Package for Sulphur Recovery Unit in Intergraph PDS. The project scope covered:

- 3D modeling of a VPSA Oxygen Package for SRU

- Modelling of Equipment / Structural Skid / Manholes / Envelope

- Piping Modeling (90 nos. of lines)

- Skid Structural Modelling & Physical Support Modeling

- All In Line Instruments like Control Valves (With Actuator removal space), PT, TG, Orifice with tapping as per HMEL/ EIL specs

- All vessel trims with Level Bridle, the Level gauge on Vessel

- Maintenance & walkway envelopes for Clash detection

Delivered

- Final 3D Model in PDS

- Isometric Drawings

- Piping BOMs

- Special support drawings with BOM

- Submission of Clash report with a resolution before 60% & 90% model review. (Each line will contain a clash-free report with itself before IFC isometric extraction)

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)