Advantages of 3D CAD Modeling for Oxygen Industry Packages

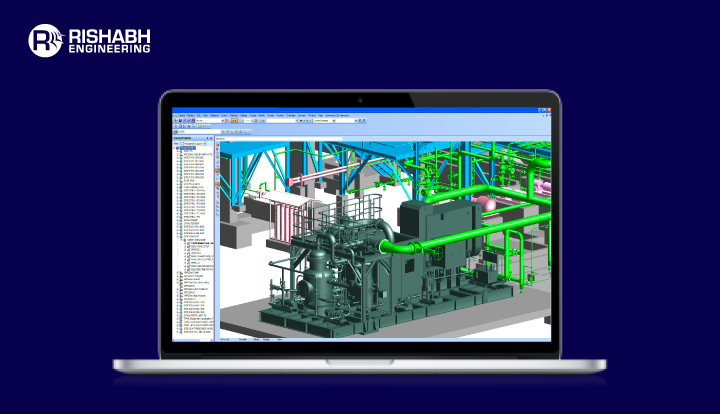

Sulfur Recovery Units are integral components of refineries and gas processing plants. They convert hydrogen sulfide (H2S) from hydrocarbon feedstock into elemental sulfur. Here, oxygen is a critical element for the combustion process that transforms H2S into sulfur, and the VPSA (Vacuum Pressure Swing Adsorption) Oxygen Package is designed to efficiently supply the required oxygen while ensuring safe & continuous SRU operation. Traditionally, the design and optimization of such complex packages involve intricate manual calculations and 2D drawings. Today, in the realm of 3D Modeling – Hexagon’s Plant Design Software (PDS)® has emerged as an evolving technology for meeting higher production goals and complying with stricter regulatory requirements for building better manufacturing plants. It is a powerful plant design software that has emerged as the front-runner for this industrial engineering requirement.

In this blog, we’ll discuss the 3D modeling benefits of the VPSA Oxygen package by utilizing Hexagon’s PDS, and its importance for the Sulfur Recovery Unit (SRU), while showcasing a case study from the real world.

Let’s get started!

Advantages of 3D Modeling for VPSA Oxygen Package

- Enhanced Visualization: It enables engineers to create a detailed, three-dimensional representation of the VPSA Oxygen Package. This visualization offers a better understanding of the package’s components, layout, and interconnections. Further, they could identify potential clashes, interferences, or design inefficiencies early in the process while reducing the likelihood of errors during the implementation phase.

- Optimized Space Utilization: The created 3D model allows engineers to explore various arrangements & orientations of equipment within the limited space available. This optimization helps minimize the physical footprint of the VPSA Oxygen Package within the SRU.

- Simulation and Analysis: A critical benefit – it enables engineers to assess the package’s performance under different operating conditions. This would include analysis of oxygen flow rates, pressure differentials, and temperature variations. And by simulating real-world scenarios, they can even fine-tune the design for optimal efficiency & reliability.

- Collaboration and Communication: Further, the 3D model is a powerful communication tool for cross-functional teams involved in the project. It would include engineers, designers, and stakeholders to review the model, offer insights, and provide feedback, streamlining the decision-making process and fostering collaboration.

- Reduced Construction and Operational Risks: By identifying and rectifying design flaws in the early stages of construction, the 3D model helps mitigate risks associated with rework, delays, and cost overruns. This accurate representation of the VPSA Oxygen Package contributes to a safer & more efficient installation and operation.

Hexagon’s PDS has emerged as the go-solution for organizations with capabilities that extend beyond traditional design software, offering comprehensive project planning, modeling, simulation, and collaboration. For the VPSA Oxygen Package, Hexagon PDS enables the Rishabh Engineering team with a robust platform to visualize, simulate, and optimize the oxygen supply system.

Importance of VPSA Oxygen Package in Sulfur Recovery Unit

The VPSA Oxygen Package is vital for an SRU, as it helps ensure the system’s efficiency, safety, and continuous operation. A critical component for refineries & gas processing plants, it converts H2S – a noxious and hazardous compound – into elemental sulfur. As part of this process, oxygen is a crucial catalyst that enables the combustion of H2S to yield elemental sulfur.

Essentially the VPSA Oxygen Package serves as the essential oxygen supply system for this combustion process, and it helps with addressing the listed pivotal purposes:

1. Oxygen Source for Combustion:

- Core function of the VPSA Oxygen Package

- Reliable and consistent source of oxygen for the controlled combustion of hydrogen sulfide

- Converts H2S into sulfur and produces heat (byproduct for maintaining optimal reaction conditions)

2. Efficiency Enhancement:

- Efficient oxygen supply is fundamental for higher efficiency in SRU

- Designed package ensures precise oxygen delivery for overall process efficiency & enhanced sulfur recovery rates

3. Safety Assurance:

- Designed package provides a regulated & reliable oxygen supply

- Minimizes risk of uncontrolled reactions, backfires, or other safety-related concerns

- It maintains a safe working environment for operators & prevents potential accidents

4. Environmental Compliance:

- Designed package ensures the combustion process within the SRU is optimized, resulting in reduced emissions of sulfur dioxide (SO2) – a pollutant with adverse environmental impact

The VPSA Oxygen Package is a critical component of SRU as it enables the controlled combustion of hydrogen sulfide and the subsequent conversion into elemental sulfur. It provides a reliable and efficient oxygen supply while ensuring the operational excellence of the SRU and contributing to safety, environmental compliance & uninterrupted production. The intricate interplay between the VPSA Oxygen Package and the larger SRU underscores its significance as a fundamental component that drives the success of sulfur recovery processes in refineries and gas processing plants.

VPSA Oxygen Package Using Hexagon PDS

Our project aims to revolutionize the VPSA Oxygen Package. It is a crucial process for generating oxygen from the air for various industrial applications. While the traditional methods of designing and implementing VPSA systems were time-consuming & inefficient, our team’s innovative approach, coupled with Hexagon’s PDS 3D Modeling technology, helped redefine the entire process for the end customer.

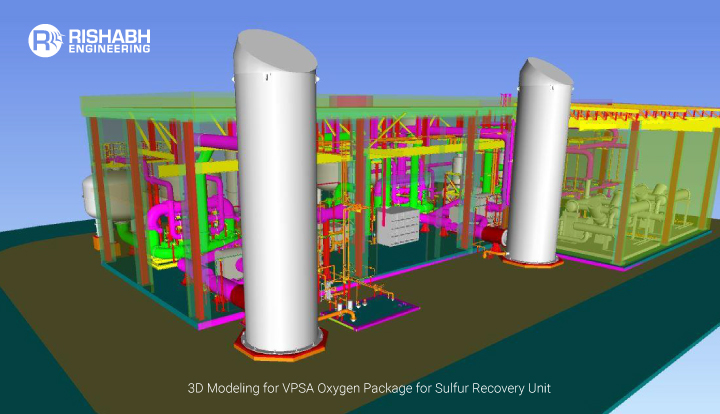

Project Showcase: 3D Modeling For VPSA Oxygen Package Of Sulfur Recovery Unit

The client is a global supplier of industrial gas plants with associated technical solutions and engineering services. They provide 360o engineering solutions from conceptual design to EPC services, commissioning & after-sales services that meet international quality and safety standards. With a focus on cryogenic equipment, they were developing VPSA Oxygen Package for their upcoming Sulfur Recovery Unit.

Project Scope:

With Rishabh Engineering’s extensive experience in Modeling industry gas packages, the client awarded the project to our team. Our scope for this project included the following;

- Modeling of Equipment / Structural Skid / Manholes / Envelope by utilizing Hexagon’s PDS

- Piping Modeling (90 nos. of lines as per updated P&IDs received)

- Skid Structural Modelling & Physical Support Modeling

- Maintenance & walkway envelopes for Clash detection

For this project, below were the key considerations:-

| Description | Nos. |

| Total Number of Small Mechanical Equipment | 20 |

| Total Number of Lines as per updated P&IDs | 90 |

Software Technologies Utilized:

- 3D Modeling – Hexagon PDS & AutoCAD – 2015

- Clash Detection & Review – Navisworks Manage 2016

Final Words

Sulfur Recovery Units are vital to refineries & gas processing plants as they catalyze the conversion of hydrogen sulfide to elemental sulfur, which relies on oxygen’s combustion process. As part of this, developing the VPSA Oxygen Package guarantees continuous SRU operation. While traditionally, such intricate systems rely on manual calculations and 2D drawings. And, multidisciplinary engineering service providers, like Rishabh Engineering have hands-on experience in utilizing advanced technologies like Hexagon’s PDS for 3D Modeling. The benefits of 3D Modeling in engineering include driving progress, improving efficiency, and ensuring the sustainability of industrial operations.

The success of the above-listed case study showcases the power of 3D Modeling in revolutionizing complex engineering projects. 3D CAD modeling services underscore the role in shaping the future of industrial design and optimization. In this blog, we’ve attempted to showcase the transformative potential of 3D Modeling & benefits of 3D CAD facilitated by Hexagon PDS. This paradigm shift empowers engineers to visualize, simulate, and optimize the oxygen supply system, signifying a bold step toward precision and innovation. Combining skills, technology & complex industrial processes redefines the industrial engineering package development landscape. The PDS 3D Modeling project for VPSA Oxygen Packages by Rishabh Engineering has helped the oxygen industry, elevating it to new efficiency, safety, and sustainability levels. The cutting-edge technology offers enhanced visualization, streamlined collaboration & a more efficient design process, resulting in cost savings, faster time-to-market & improved environmental impact.

Seek Help With 3D Modeling For Industrial Processes?

We can help you revolutionize efficiency and safety by embracing the future of precision and collaboration with Hexagon PDS.

Related Blogs

Related Blogs

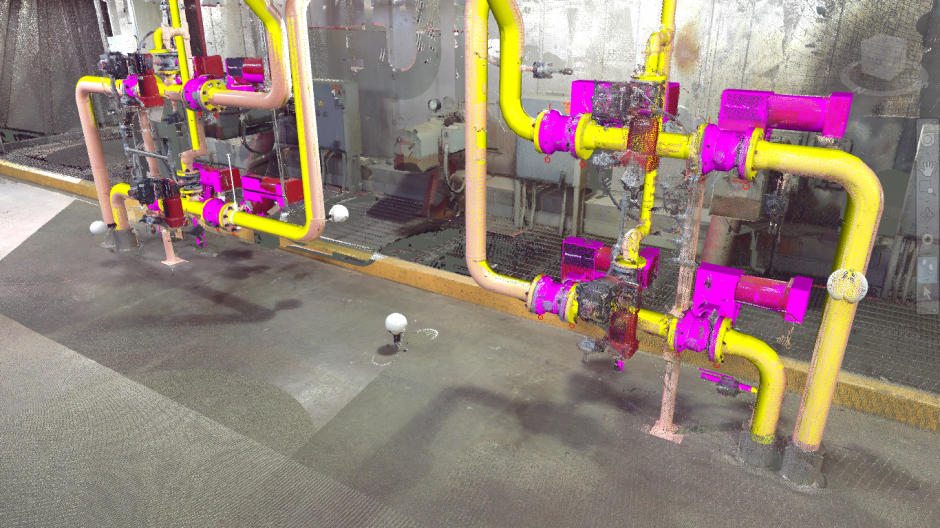

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…