Project Information

Industrial Fire Hydrant System Design For Chemical Processing Plant

Description

Client

An India-based manufacturer of chemicals and specialty chemicals used in the downstream manufacturing of agrochemicals, polymers, additives, surfactants, pigments & dyes.

Engineering Requirement

The client sought comprehensive engineering support with industrial fire hydrant system design for their upcoming chemical processing facility.

The Rishabh Engineering team conducted detailed engineering, specifically focusing on designing fire hydrant systems that were integral to the project. With meticulous planning and design, our detailed engineering services team designed layouts for fire hydrants that align precisely with the project’s stringent requirements. Leveraging our experience helped ensure seamless integration and adherence to the highest safety standards, providing the client with peace of mind and confidence in their project’s safety infrastructure.

Safety Compliance:

- Ensure compliance with relevant safety regulations and standards.

- Conduct thorough risk assessments and hazard analyses.

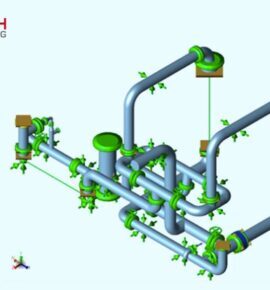

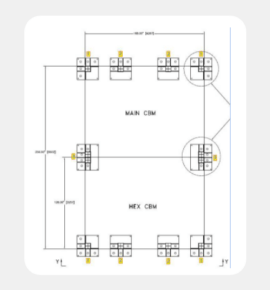

Efficient Fire Hydrant System Layout Design:

- Optimize the layout for efficient operation and maintenance.

- Minimize obstructions and maximize accessibility.

Equipment Accessibility:

- Ensure easy access to fire hydrants, hose reels, safety showers, and fire extinguishers.

- Consider accessibility for maintenance and inspection activities.

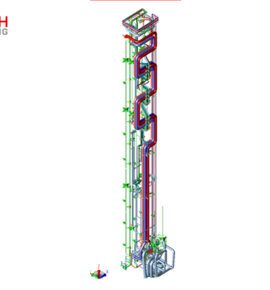

Integration with Existing Systems:

- Coordinate with other engineering disciplines to integrate fire hydrant systems seamlessly into the overall facility design.

- Ensure compatibility with existing infrastructure and systems.

Timely Execution:

- Adhere to project timelines and milestones.

- Implement efficient project management practices to ensure timely delivery.

Engineering Deliverables:

- Detailed fire hydrant system design drawings, including riser diagrams, layout plans, and installation details.

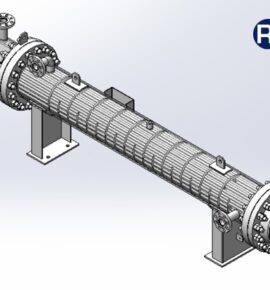

- Specifications for fire hydrant equipment and components.

- Compliance documentation demonstrating adherence to safety standards and regulations.

- Integration plans outlining how fire hydrant systems will interface with other building systems.

- Execution schedule outlining the design, procurement, installation, and testing timeline.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)