Project Information

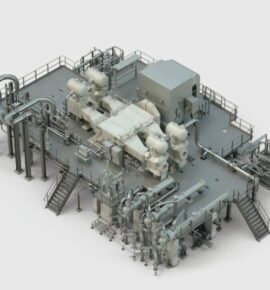

Flooded Evaporator Design For Chilling Plant

Description

Client

A US-based manufacturer of engineered cryogenic gas processing equipment and small-scale process plants for liquefied natural gas (LNG), well services, and industrial gas industries with a significant presence in Southeast Asia.

Engineering Requirement

The client aimed to enhance their chilling plant operations’ thermal efficiency and reliability with a flooded evaporator design, specifically focusing on the flooded evaporator used within the plant. They sought expertise in thermal design to facilitate efficient heat exchange between refrigerant R134a and air within a shell and tube heat exchanger.

Given its reputation for excellence in equipment engineering solutions, Rishabh Engineering was chosen to develop a report for flooded shell and tube evaporator design. Leveraging AspenTech’s Exchanger Design & Rating (EDR)™ and AutoDesk AutoCAD, our team embarked on the following tasks:

Thermal Design Report for Flooded Type Shell And Tube Evaporator:

- Our team comprehensively analyzed the thermal design aspects of the shell and tube exchanger.

- Key parameters such as heat transfer coefficients, heat transfer area, and thermal and hydraulic analysis summary were meticulously documented.

- Fluid flow rates and temperature differentials were analyzed to ensure optimal performance and efficiency of the chilling plant.

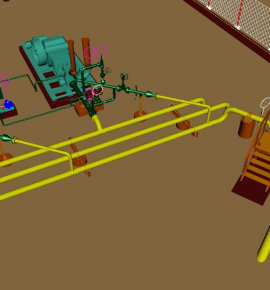

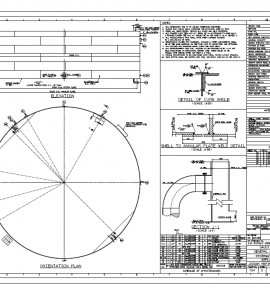

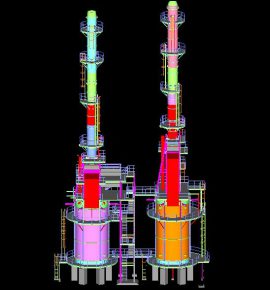

Mechanical GA Drawing:

- Detailed mechanical general arrangement drawings were created, encompassing dimensions, specifications, and essential features.

- These drawings were a crucial guide for the manufacturing and installation processes, ensuring accuracy and adherence to design specifications.

The flooded shell and tube heat exchanger design for a BXM TEMA-type configuration was a critical component of the chilling plant. It featured a Vapor Disengagement chamber at the top and a Knockout drum at the air outlet side to effectively remove moisture from the system.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)