Project Information

Thermal Design of Dry Expansion Heat Exchanger

Description

Client

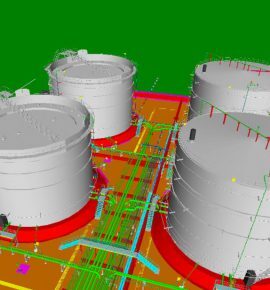

A US-based manufacturer of engineered cryogenic gas processing equipment and small-scale process plants for liquefied natural gas (LNG), well services, and industrial gas industries with a significant presence in Southeast Asia.

Engineering Requirement

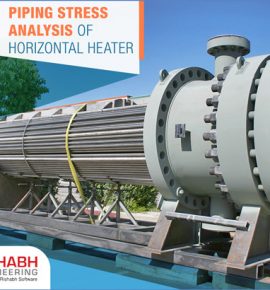

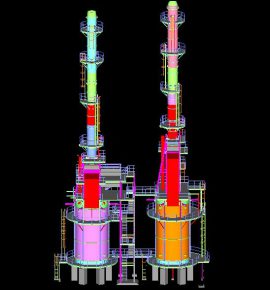

In the context of a Chilling Plant requiring effective air cooling, the Dry Expansion (DX) type of shell and tube heat exchanger plays a pivotal role. Our experienced equipment engineering services team was commissioned to validate the dry expansion heat exchanger thermal design, conduct thermal rating assessments, and optimize both internal design and volume considerations for the heat exchanger. The objective was to ensure optimal heat exchange between refrigerant R134a and Saturated Air, fostering efficient air cooling while minimizing energy consumption.

Harnessing the capabilities of AspenTech’s Exchanger Design & Rating (EDR)™, Rishabh Engineering worked on dry expansion evaporator thermal design. The core activities included:

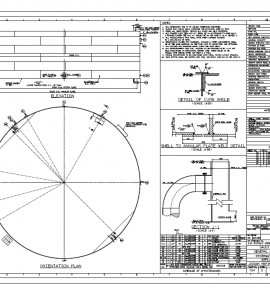

Thermal Design Report for Heat Exchanger:

- Detailed scrutiny of the existing design to identify strengths and areas for improvement.

- Rigorous validation of thermal ratings to ascertain compliance with performance requirements.

- Formulating recommendations for enhancing internal design features to augment heat transfer efficiency.

- Devising strategies for volume optimization to streamline the heat exchanger’s footprint while maintaining functionality.

The DX-Type Shell and Tube Heat Exchanger:

Characterized by its NEU TEMA-type configuration, the DX-type Shell and Tube Heat Exchanger was the cornerstone for facilitating dry-type evaporator thermal design between refrigerant R134a and Saturated Air within the Chilling Plant. The primary aim was to achieve superior heat transfer efficiency while minimizing energy consumption, thereby optimizing operational costs.

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)