Green hydrogen is now a crucial component of the global decarbonization effort. Hydrogen produced from renewable energy sources offers a feasible alternative to fossil fuels as companies look for less harmful alternatives. Nevertheless, in addition to renewable electricity, systematic and organized contribution of process engineering is required for the effective and extensive production of green hydrogen. The design, optimization, and upkeep of the systems that convert water and renewable energy into high-purity hydrogen are mostly the responsibility of process engineers. It guarantees the efficient integration of all parts, from compressors to electrolyzers, leading to enhanced output, reduced losses, and enhanced safety.

In this blog, we’ll talk about the essentials of process design for a green hydrogen production plant, with specifics on key factors in process design, challenges and important safety considerations & how Rishabh Pro Engineering can help.

Basics of Green Hydrogen Production

What is Green Hydrogen?

Green hydrogen is an energy source produced by splitting water with electricity from wind and solar power. In contrast to conventional hydrogen, which is made using fossil fuels, green hydrogen doesn’t release any greenhouse emissions. Globally, it is gaining traction as nations seek to reduce carbon emissions and switch to cleaner energy. Green hydrogen provides a feasible route to decrease decarbonization for hard-to-electrify industries including steel, cement, shipping, and aviation. With its capacity to store energy, promote renewable energy sources, and lessen reliance on fossil fuels, it is quickly emerging as a key component of upcoming global energy plans. Read this blog to learn more about the current state of green hydrogen production, its benefits, processes, key advancements.

Overview of Green Hydrogen Production Methods

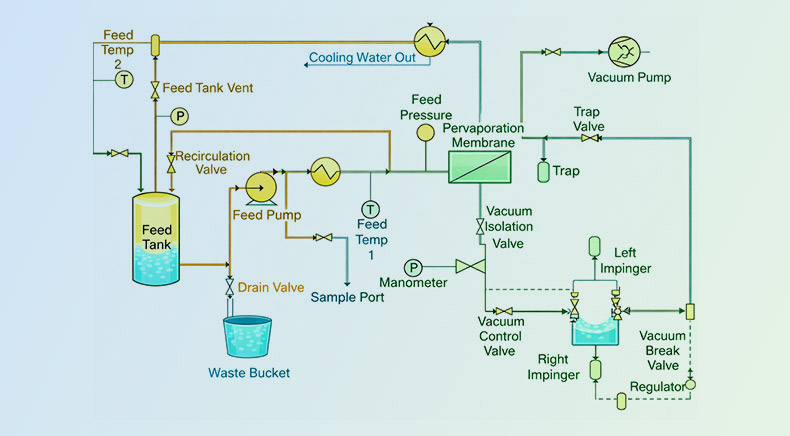

A green hydrogen plant’s design must be carefully planned for both efficiency and safety. Use of strong, suitable metals, such as stainless steel or specific alloys, is crucial since Green H2 can weaken some materials. Systems like pipes and vessels must be designed to withstand stress because of the high pressure and temperature during production. Because hydrogen is extremely combustible and spreads quickly, ventilation and leak detection are also essential. Systems for emergency shutdown must be prepared to quickly isolate dangerous areas. Finally, early risk identification is aided by safety studies such as HAZOP. Read this blog to learn more about Green Hydrogen Production Process & Key Components.

These solutions are applied across the full design and can be expertly guided by engineering partners like Rishabh Pro Engineering. For a green hydrogen plant to function optimally, a detailed understanding of its components is crucial. Listed below are a few key systems typically found in such plants:

- Electrolyzer Stack: This is the heart of the hydrogen production process. It’s where water is split into hydrogen and oxygen using electricity. This stack comprises several small cells where this reaction happens. The better this system works, the more hydrogen you get efficiently.

- Water Treatment Unit: Hydrogen production needs very pure water. This unit cleans the water to remove any minerals or impurities that could damage the electrolyzer or reduce its efficiency. It acts like a filter to make sure only the cleanest water is used.

- Power Supply System: Since hydrogen is made using electricity, a steady and reliable power source is critical. This part of the system ensures that the electrolyzer gets the right amount and type of electricity—whether it comes from solar panels, wind turbines, or the main grid.

- Cooling System: This unit gets hot when it’s running, so a cooling system is needed to keep temperatures under control. This prevents overheating and ensures that all parts work efficiently and safely over long periods.

- Hydrogen Drying and Compression: Once hydrogen is produced, it’s not quite ready to use. First, it needs to be dried to remove any moisture left from the process. Then, it is compressed so it can be stored in tanks or transported efficiently.

Key Process Engineering Concepts Applied to Green Hydrogen Production

To maximize efficiency and safety in the production of green hydrogen, fundamental process engineering concepts including thermodynamics, reaction kinetics, and mass and energy balance must be applied. These ideas are essential to guaranteeing high-performance, sustainable hydrogen production, whether by electrolysis or other methods.

- Mass And Energy Balances: When increasing the production of green hydrogen to meet rising demand, it is essential to accurately calculate inputs and outputs to minimize waste and energy consumption.

- Reaction Engineering and Thermodynamics: To maximize hydrogen yield while reducing energy consumption and side reactions, process engineers adjust variables like temperature, pressure, and electrical current. This helps to ensure the sustainability of the process.

- Fluid Dynamics in Electrolyzers: The maintenance of constant reaction rates in electrolyzers depends on fluid dynamics, which enhances equipment longevity and hydrogen generation efficiency while lowering operating costs.

- Renewable Energy Integration (Solar, Wind, Hydro): To be considered truly “green,” electricity powering electrolyzers must come from renewable sources. Process engineering ensures seamless integration of variable energy sources (like wind and solar) with continuous hydrogen production, using smart energy buffering and real-time controls.

Key Factors In Process Design Of A Green Hydrogen Production Plant

Electrolysis Methods

The foundation of green hydrogen production lies in electrolysis — a process that splits water into hydrogen and oxygen using electricity. Additionally, the distinct technical designs, materials, and operating conditions of the three main types—solid oxide, PEM, and alkaline— would affect the performance, cost, and applicability for different hydrogen production applications. Let’s go through them.

- Alkaline Electrolyzers: These are the oldest and most widely used type. They use a liquid alkaline solution—usually potassium or sodium hydroxide—as the electrolyte. They’re quite affordable and reliable, but they don’t produce hydrogen as quickly because they work at lower current densities. This makes them better suited for steady, continuous operations rather than fluctuating energy sources.

- PEM (Proton Exchange Membrane) Electrolyzers: These use a solid polymer membrane instead of a liquid, which makes the system more compact and easier to handle. They respond very quickly to changes in power, which is perfect for renewable energy sources like solar or wind, where the power supply isn’t always steady. Though more expensive than alkaline types, their flexibility and efficiency make them popular for modern green hydrogen projects.

- SOEC (Solid Oxide Electrolysis Cells): These operate at very high temperatures—over 700°C—and can even make use of waste heat from other processes. By doing this, they reduce the amount of electricity needed to split water into hydrogen and oxygen. They’re still being developed for large-scale use, but their energy-saving potential makes them very promising for future hydrogen production systems.

Design and Optimization of Electrolysis Units

- Stack Design Considerations: When designing electrolyzers, process engineers must carefully select the right cell sizes, electrode materials, and membranes. These factors affect both the initial cost and the efficiency of hydrogen production. Choosing the wrong materials or sizes could lead to higher energy consumption and a reduced lifespan of the equipment. An experienced design engineering company could assist in conducting the required validation checks.

- Efficiency Enhancement Techniques: There are several ways to increase the efficiency of hydrogen production in electrolysis. For example, using high-purity water ensures that the electrolysis process runs smoothly without contaminating the cells. Additionally, optimizing pressure conditions and recycling waste heat (such as from the electrolysis process) can reduce energy consumption and increase the system’s overall output.

Process Safety Engineering in Hydrogen Systems

- Hydrogen Handling and Containment: Hydrogen is a highly flammable gas and is prone to leak, making it critical to design systems that can safely handle it. This includes using advanced seals to prevent leaks, ensuring proper venting to release pressure safely, and equipping the system with explosion-proof electrical components to avoid ignition risks.

- Risk Assessment Techniques (HAZOP, FMEA): To ensure the safety of the hydrogen production process, engineers use structured risk assessment methods like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis). These techniques help identify potential weaknesses in the system that could lead to failure. With this information, engineers can design backup systems and redundant safety measures to protect against accidents.

Control Systems and Instrumentation in Hydrogen Production

- Process Automation: Advanced control systems, like Distributed Control Systems (DCS), are essential for keeping the hydrogen production process running smoothly. These systems automatically adjust variables such as voltage, temperature, and flow rates in real time to optimize the process, ensuring consistent and efficient output without the need for manual intervention.

- Monitoring and Real-Time Data Analytics: In modern hydrogen production plants, sensors continuously monitor key parameters and collect data on system performance. This data is analyzed in real time, allowing for predictive maintenance. By identifying potential issues before they occur, engineers can perform repairs or adjustments, minimize downtime and maximize plant efficiency.<

Materials and Corrosion Considerations

- Selecting Materials for Electrolyzers: The components of electrolyzers must be chosen carefully to withstand the harsh conditions of the process. Since these units are exposed to electrolytes, high pressures, and elevated temperatures, materials like stainless steel, nickel alloys, and even platinum coatings are often used due to their resistance to corrosion and wear.

- Mitigating Corrosion in Harsh Environments: Corrosion can significantly reduce the lifespan of critical components, so choosing the right materials is only part of the solution. Proper coatings and surface treatments, along with controlling the operating conditions (such as temperature and chemical exposure), can further prevent corrosion and extend the life of the electrolyzers.

Water Treatment and Feedstock Preparation

- Purity Requirements: The purity of the water used in electrolysis is crucial. Even small amounts of impurities can reduce the efficiency of the electrolyzer or damage its components. Therefore, water used in electrolysis must often be deionized or purified to ultra-pure levels.

- Reverse Osmosis and Deionization Units: To achieve the necessary water purity, processes like reverse osmosis and deionization are commonly used. These methods remove dissolved minerals, salts, and other impurities, ensuring that only the highest-quality water enters the electrolyzer, thereby protecting sensitive components like membranes and catalysts from degradation.

Heat Integration and Energy Recovery

- Waste Heat Utilization: One of the benefits of electrolysis is that it generates heat as a byproduct. Rather than letting this heat go to waste, it can be captured and used for other purposes, such as district heating (to warm buildings or industrial processes) or preheating water before it enters the electrolyzer. This not only improves the overall efficiency of the plant but also reduces the need for additional energy sources.

- Improving Thermal Efficiency: Techniques like pinch analysis can be used to identify and minimize energy losses in the system. By integrating thermal loops, heat that would normally be wasted can be recovered and reused, further improving the overall energy efficiency of the hydrogen production process.

Process Intensification in Green Hydrogen

- Modular Design Approaches: Modular design involves creating smaller, standardized units that can be scaled up as needed. This approach is particularly useful for hydrogen production in remote locations or for smaller-scale applications. It allows plants to be built and expanded more quickly and efficiently, without the need for large, one-size-fits-all infrastructure.

- Integration with Other Green Processes (e.g., CO₂ capture): To maximize environmental benefits, hydrogen production can be integrated with other green processes, such as carbon capture or ammonia synthesis. This can create a more sustainable and circular approach to industrial operations, where hydrogen production and CO₂ capture work together to reduce emissions and improve the overall environmental impact.

Safety Considerations in Green Hydrogen Plants

Safety is a top priority in green hydrogen plants, where the production, storage, and handling of hydrogen involve significant risks. To ensure a safe and compliant operation, comprehensive safety considerations must be integrated throughout the plant’s design, operation, and maintenance phases.

Key safety measures include:

- Leak Detection and Prevention: Hydrogen is highly flammable, so early detection of leaks is crucial. Advanced sensors and real-time monitoring systems help ensure rapid response to potential hazards.

- Pressure Control Systems: Hydrogen systems operate under high pressure, which requires robust pressure relief mechanisms and regular maintenance to prevent dangerous over-pressurization.

- Ventilation and Exhaust Systems: Proper ventilation helps disperse hydrogen gas in case of a leak, reducing the risk of combustion or explosions. Effective exhaust systems direct gases safely away from the plant.

- Fire and Explosion Risk Management: Implementing explosion-proof equipment, fire suppression systems, and clear emergency protocols mitigates the risk of catastrophic events.

- Employee Training: Ensuring that all personnel are trained in hydrogen safety, emergency response, and handling protocols is vital to prevent accidents and reduce human error.

- Safety Regulations and Standards: Compliance with industry standards (e.g., NFPA, IEC) and local regulations ensures that safety measures meet established guidelines, minimizing risk exposure.

Challenges in Process Design for Green Hydrogen Production Plant

It’s not easy to design effective hydrogen systems. To make green hydrogen scalable and commercially feasible, process design must get past financial and technological obstacles brought on by changing technologies and substantial economic risks.

Technological Barriers in Green Hydrogen Production:

- Limited efficiency and scalability of current electrolyzer technologies

- Integration challenges with intermittent renewable energy sources (solar, wind)

- Need for robust materials to handle high pressures and corrosive environments

- Lack of standardized designs for emerging hydrogen technologies

Economic Challenges and Cost Considerations:

- High capital and operational costs of hydrogen production infrastructure

- Uncertain return on investment due to evolving market and policy landscapes

- Difficulty in securing funding for pilot or early-stage projects

- Cost competitiveness with fossil fuel-based hydrogen remains a major hurdle

How Rishabh Pro Engineering Facilitates Process Engineering for Green Hydrogen Production?

At Rishabh Pro Engineering, we apply a strategic approach to process engineering that ensures the efficient, safe, and sustainable production of green hydrogen. Our expert team utilizes advanced engineering principles and cutting-edge technologies to optimize every aspect of the hydrogen production process, from the core production methods to the Balance of Plant (BoP) systems.

Here’s how we facilitate process engineering for green hydrogen production:

- Optimizing Process Design: We focus on refining the design of hydrogen production systems, ensuring that processes like electrolysis are optimized for maximum efficiency, safety, and scalability.

- Energy and Mass Balance: By calculating precise mass and energy inputs and outputs, we ensure minimal waste and energy consumption, which is vital when scaling up hydrogen production plants.

- Reaction Engineering: Our engineers fine-tune reaction conditions (e.g., temperature, pressure, and electrical current) to maximize hydrogen yield while minimizing energy usage and preventing side reactions that could reduce system efficiency.

- BoP System Integration: Beyond the core production system, we ensure that all auxiliary systems—such as power supply, water treatment, cooling, and safety mechanisms—are seamlessly integrated and optimized to support overall hydrogen production.

- Sustainability Focus: We prioritize renewable energy integration, enabling the use of solar, wind, or other green sources to power the hydrogen production process, further aligning with global sustainability goals.

- Risk Assessment and Safety: Our team conducts rigorous safety studies (like HAZOP) to identify and mitigate risks, ensuring the hydrogen production plant operates smoothly and safely.

Future Outlook

The effective design and optimization of green hydrogen production is essential as it emerges as a key answer for global decarbonization. By using cutting-edge methods to optimize production, boost safety, and strengthen system integration, process engineering becomes essential to the success of green hydrogen projects. We assist in maximizing the efficiency and scalability of hydrogen production facilities by concentrating on crucial aspects including mass and energy balancing, reaction engineering, and BoP system integration. Our strategy integrates renewable energy sources to ensure the process’s environmental viability while highlighting both technical excellence and sustainability. Apart from refining the fundamental systems, our team’s proficiency in risk assessment, safety investigations, and process optimization guarantees that all plant components operate seamlessly, mitigating any risks and optimizing efficiency. Our process engineering services are essential in overcoming technological and financial obstacles as green hydrogen technology develops further, assisting clients in making the shift to a low-carbon, sustainable energy future.

Frequently Asked Questions

Q: How does process engineering help make hydrogen production more efficient?

A: It’s all about making the system work better. Engineers look at how to get the most hydrogen while using the least amount of electricity, choosing materials that last longer, and designing systems that save energy and reduce costs.

Q: What safety steps are needed when making hydrogen?

A: Hydrogen is very flammable, so safety is a top priority. This means using equipment that won’t spark, making sure the area is well-ventilated, and installing sensors that can detect leaks quickly. Engineers also plan for worst-case scenarios to keep people and the facility safe.

Q: What happens to the extra heat from making hydrogen?

A:When hydrogen is produced, some heat is also created. Instead of wasting it, this heat can be reused—for example, to warm up the water going into the system or even to heat nearby buildings. This helps save energy and reduces waste.

Q: What materials are used to build hydrogen-making equipment?

A: Since the equipment needs to handle tough conditions like high heat and pressure, strong and long-lasting materials are used. These include stainless steel and special coatings that resist rust and wear.

Q: What is a PFD and why is it useful in hydrogen production?

A: A Process Flow Diagram (PFD) is like a map that shows how the hydrogen plant works—from water treatment and electricity input to hydrogen drying and storage. It helps engineers see how everything is connected and plan better before construction begins.

Q: Why use a modular design in green hydrogen projects?

A: Modular design means building the plant in smaller, ready-to-go units. These units are easier to install, move, or expand, especially in remote areas where building a big plant might not be possible.