Advantages of 3D CAD Modeling in Engineering

The significance of accurate design and documentation can’t be stressed enough in the world of operations and maintenance (O&M) especially in the oil and gas sector, given the scale and complexity of projects. Whether it is basic plant engineering, piping design, piping stress analysis, commissioning, review of design and detailed engineering services, transfer of data from facility engineers to O&M team– advanced software and 3D designs are crucial for operational readiness to improve asset data builds for plants – the importance of 3D CAD Modeling becomes evident as the industry becomes more digital.

With increased international competition, escalating costs and fluctuating energy prices, there is great emphasis on improving profitability with leaner projects and shorter turn-around times. The oil and gas sector is now heavily reliant on data and technology to provide a competitive advantage. Let’s analyze the benefits of 3D modeling in engineering to optimize operational efficiency:

Advantages of 3D CAD Modeling:

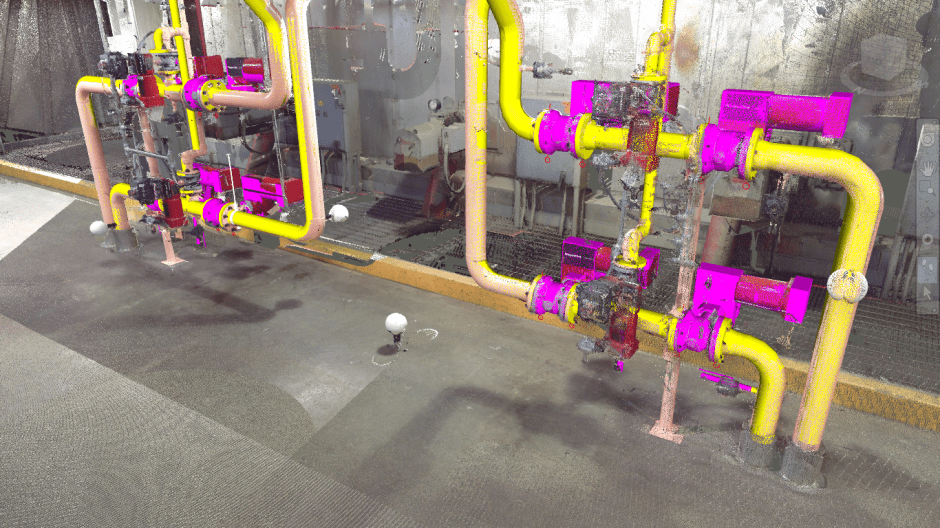

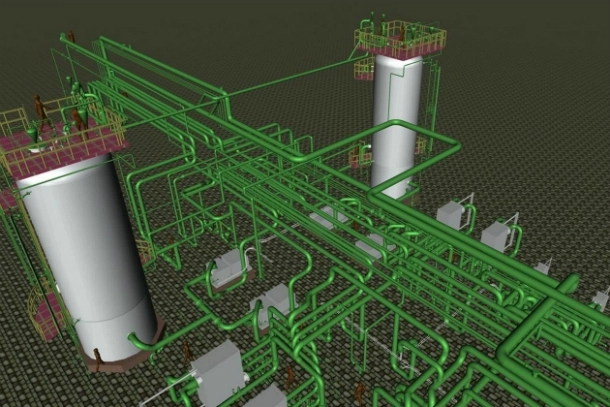

- Simplified and improved piping design: 3D CAD modeling helps in streamlining the iterations with user-friendly pipe routing. The sophisticated capabilities of 3D CAD software combined with engineering and designed input produces complete 3D pipelines with appropriate fittings from sketched paths with additional component and setting up of required connections. These software are enabled to validate the conformity of components to characteristics like diameter, pressure, etc., leading to highly accurate pipeline design and process reliability. Smart P&ID can enable creating piping & instrument diagram as per process.

- Better visualization and future forecasting capabilities: 3D CAD modeling software helps in productivity savings for key plant design disciplines. It allows owner-operators and Engineering, Procurement and Construction (EPC) companies to visualize the final plant better and the ability to make intelligent, data-driven decisions and forecasts. Moreover, clients have visibility of multiple ‘what-if’ scenarios during the design process. The creation of virtual models enables non-CAD and non-design stakeholders to participate in the process.

- Enhances designer output: 3D CAD modeling makes better use of the designer resources by taking away the manual and tedious part of designs. It also helps the designer visualize all components in 3D during the initial design stage and modify/edit instantly, if need be. This reduces the number of iterations and improves designer productivity.

- International codes and standards compatibility: Compliance with international codes and standards for various processes and plant designs becomes much easier with 3D CAD modeling as the specifications are included for each standard such as BSI, ANSI, DIN, CSN, GB, ISO etc.

- Better quality deliverables, faster and cheaper time to market: Owner-operators and EPC companies are under a great deal of pressure to meet global demands in a tough and competitive environment. Plant design software has evolved in terms of power, scope and sophistication, affording these companies the ability to deliver higher quality deliverables with a tight deadline and budget. 3D modeling also reduces remodeling between conceptual and detailed design by taking forward initial concept layouts into detailed engineering.

- Documentation: 3D modeling in engineering enhances your data management to organize and manage your design assets and documents. It allows you to standardize on the detailing and drafting procedures, automating your process and increasing speed and accuracy of output. Auto ISO generation helps in accuracy of material consumption and efficient procurement and fabrication time.

- Integration: Advanced CAD design software provides you with a single file for accurate extraction of GA, Layouts, Isometric Drawings, Cable Routing, BOM, Steel and Architectural Drawings and other documents. This gives a comprehensive overview and tighter control over the design and quality across disciplines.

To Conclude:

3D CAD Engineering facilitates each stage of design and development from concept to planning, accurate designs and documents for consultation. There are many leading plant design and 3D Modeling software with advanced capabilities, offering ample custom benefits as per the scope and complexity of projects. Some of the leading software are AVEVA PDMS, Intergraph PDS, AutoDesk, AutoCAD Plant 3D, SolidWorks, Bentley AutoPLANT and Intergraph CADWorx.

Rishabh Engineering has proven expertise in multi-disciplinary 3D drafting and modeling solutions for projects with varying and complex needs.

Are you looking for the optimum design solutions with 3D CAD engineering?

We have the expertise in multi-disciplinary 3D modeling solutions for complex projects.

Call us now: 1-877-RISHABH (1-877-747-4224)

Or

Related Blogs

Related Blogs

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…