Advantages of 3D CAD Modeling for Nitrogen Packaging

3D Modeling helps optimize efficiency and ensure product integrity for industrial packages. It is made possible with advanced computer-aided design (CAD) design techniques. Specifically for Nitrogen packaging, 3D models enable manufacturers to develop packaging systems tailored to the needs of the specific industry.

In this blog post, we will explore the benefits of 3D CAD design & how it helps enhance nitrogen packaging efficiency for packages used across varied industries while providing a walk-through of one of our recent projects.

Why 3D Modeling Is Important For Nitrogen Packaging?

3D Modeling for nitrogen packaging allows engineers to analyze the nitrogen flow dynamics, identify potential issues, and optimize the packaging configuration for effective gas distribution. It helps ensure uniform displacement of nitrogen with oxygen while creating an optimal atmosphere for preserving the freshness and quality of the packaged product. Further, with 3D Modeling in the packaging process, effective communication among stakeholders is made possible since it reduces the need for physical prototypes.

Benefits Of 3D Modeling For Nitrogen Packaging

- Custom Design: 3D Modeling for nitrogen packaging systems eliminates the traditional approach’s limitations. The CAD software enables engineers to optimize space utilization, reduce material waste, and streamline packaging.

- Efficient Workflow: The tailored design with 3D Modeling enables the creation of airtight and secure packaging while protecting products from spoilage, oxidation & contamination during storage & transportation. 3D Modeling allows engineers to preempt bottlenecks, optimize equipment placement & streamline material handling processes.

- Enhanced Product Protection: 3D Modeling helps analyze the specific product requirements using simulation tools. It enables engineers to design packaging solutions that minimize oxygen exposure, moisture ingress, and physical damage while ensuring the products reach consumers in optimal condition.

- Seamless Integration: In many manufacturing facilities, nitrogen packaging systems must integrate seamlessly with existing equipment and production lines. 3D designing allows engineers to model and simulate the integration process, ensuring compatibility and avoiding potential conflicts before implementation. This seamless integration minimizes downtime during installation and facilitates a smooth transition to the new packaging system.

- Future-Proofing and Iterative Improvements: The packaging industry constantly evolves, with new products, materials, and regulations emerging regularly. 3D designing allows manufacturers to adapt and future-proof their nitrogen packaging systems. By easily modifying the digital design, engineers can incorporate improvements, address changing requirements, and stay ahead of the competition.

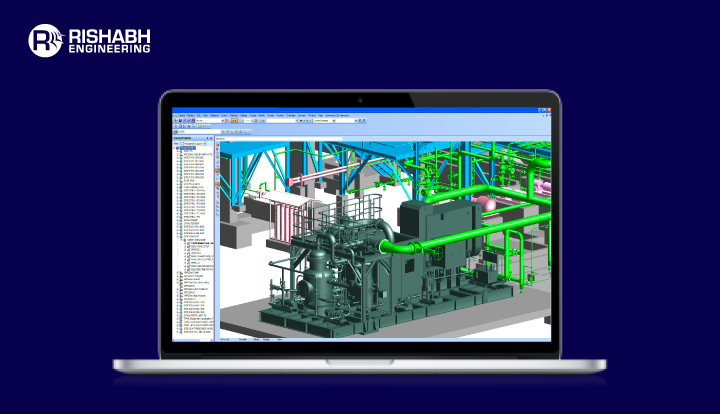

Rishabh Engineering is an award-winning 3D CAD modeling company offering various multidisciplinary plant modeling services. Our team of design engineers collaborates to utilize the advantages of 3D CAD to deliver quality modeling services for owners and Operators, OEMs, EPC & EPCM contractors, PMCs, & Technology Package Fabricators, OEMs, and utility owners with a – consortium of end users, EPC/EPCM And RESO teams.

Project Showcase

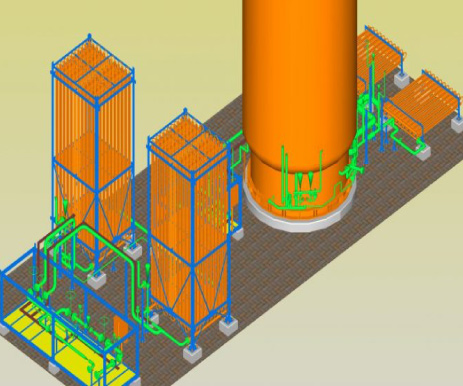

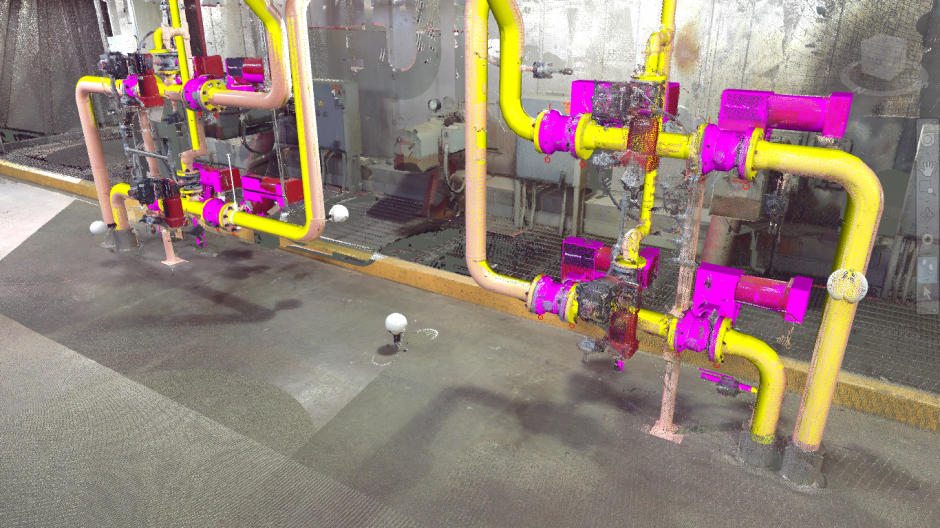

An India-based leading manufacturer of Cryogenic liquid storage and transport tanks. Also, a reputed supplier to leading international gas companies worldwide, like Air Liquide, Air Products, Linde, Messer, Taiyo Nippon Sanso & Praxair. They pursued a specialist partner to conduct 3D modeling of the Nitrogen package.

Project Scope:

- Equipment modeling

- Structural platform modeling – ladders, manholes & envelopes

- Piping design & modeling using PDS

- Physical support modeling

- Modeling of instruments, junction boxes with supports

- Modeling of electrical and structural supports

Software Technologies Utilized:

- 3D Modeling – PDS

- 2D Drawings – AutoCAD

- Review Software – Navisworks

Conclusion

Using 3D designing in nitrogen packaging has brought significant advancements to the industry. Manufacturers can optimize their nitrogen packaging systems to meet their specific needs and deliver high-quality products through customized design, enhanced product protection, efficient workflow, seamless integration, and the ability to iterate and improve. As technology continues to evolve, embracing the advantages of 3d modeling will be crucial for manufacturers aiming to stay competitive and maximize efficiency in the nitrogen packaging process.

Looking to Optimize Industrial Packaging Systems?

Our 3D CAD Design specialists can create customized designs to support & enhance your packaging efficiency.

Related Blogs

Related Blogs

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…

I’m genuinely impressed by the quality of your blog – it’s informative, engaging, and incredibly well-written!