Hazards and Consequences of Piping Design Failures

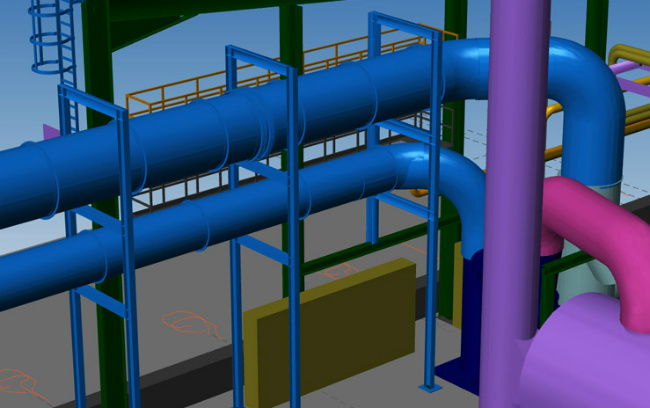

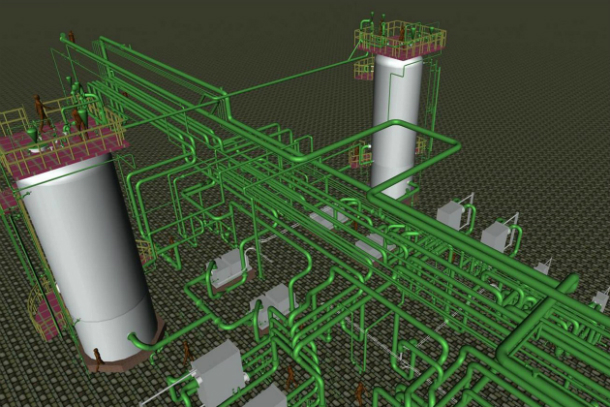

Piping is the life force of any process plant. And while it may seem like a relatively modern, post industrial revolution discipline, pipes and piping design have been integral to civilization since pre-historic times. The use of piping design and engineering is evident in the remains of many ancient civilizations, emphasizing its importance to society. Piping design is considered to be one of the more difficult disciplines and design engineers and piping design service providers are highly sought after.

Precision and safety

Needless to say piping systems should be designed with precision and care. The efficiency of a plant depends very highly on its ability to transport fluid/gases/material through the pipes to various equipment that function in tandem. Fortunately, many standard practices and codes have emerged for piping design and today it is a major engineering discipline. As such, there is high demand for trained piping design engineers and consultants in various sectors owing to various materials, high temperature conditions, high pressure etc. Poor piping design can thus have many severe consequences.

Issues caused by faulty piping design

A failure, or ‘incident’ is when a ‘system’ breaks down. In the context of piping – it could mean the coating is faulty, the cathodic protection insufficient, there may be failure to detect corrosion, inaccurate vibration and stress analysis. Often a lot of incidents or failures can be avoided if due care is taken at the design stage.

Important issues that may occur due to faulty piping design:

Corrosion in Piping

Unprotected or poorly coated pipelines corrode and deteriorate. Corrosion is one of the biggest culprits causing piping failure. Effective design and installation of the piping, along with choosing the correct piping material can ensure that there is no corrosion.

Equipment failure

Misalignment issues caused by contraction or expansion in a poor design can result in a huge equipment failure. Equipment failures have the potential to cause fire, shutdown and revenue loss. This is why a good design and analysis/review are necessary to identify potential problems and pitfalls. Flexible routing is the first and by far the cheapest and safest method for handling expansion in piping systems.

Vibration of Equipment

Piping systems are often prone to vibration-induced failures. Piping vibration assessment (thermal analysis) is necessary at the design phase and high-risk locations are generally tested during the implementation phase. Piping vibration analysis follows specific guidelines and methodologies to ensure public and employee safety.

From public safety and health perspective too, vibration analysis is vital. It is estimated that 21% of hydrocarbon releases are due to vibration-induced fatigue failures. These releases bear a severe impact on public and employee safety, the environment, production and financial performance. Piping vibration risks can be detected soon enough if companies have systematic approach to design and risk evaluation.

Stress in piping systems

Stress exists in almost all piping systems. Improper calculation of stress can cause system failure and poor execution. That is to say, two piping systems that have the same size, shape, pipes, temperature and material but different wall schedules will have different stress. Force in piping design is not independent of other factors. Force is the result of expansion or pressure acting on the configuration that might be too stiff. This can cause the piping support system to break down or damage the equipment.

Weather and climate conditions

Ambient temperature and weather/climate affect the performance of piping systems. A piping system transporting extremely hot fluids/gases in very cold climates faces the risk of bursts/fractures and vice versa. Piping design therefore must consider appropriate thermal insulation to protect against outside weather and moisture intrusion.

Venting hazardous chemicals

Venting of hazardous fluids and chemicals requires additional safety measures. Process piping design that fails to check these might inadvertently cause the toxic fumes to vent into work spaces or maintenance shafts where personnel might be located.

Summary

As seen here there are a number of things that can go seriously wrong if the piping design is poor or doesn’t take into consideration all aspects of piping schematics. Professionally designed piping systems take into consideration a wide range of issues, industry-specific procedures and international codes that ensure that these risks are suitably mitigated.

Therefore, choosing the right piping design company is crucial to your project’s success and efficiency. Here are few important questions that will help you select the right piping design partner.

Many companies like Rishabh Engineering specialize in providing piping design services to various sectors like Oil & Gas, Process industries like Petrochemical, Pharmaceutical, Fertilizer and Utilities such as Water & Effluent Treatment and Power.

Want to know more about Piping Design from a Team of Engineering experts who have a track record of providing leading Piping Design Solutions?

Call: 1-877-RISHABH (1-877-747-4224) OR Contact us

Related Blogs

Related Blogs

Piping Support Design and Engineering

Pipe support design is an important component of piping engineering…

Detailed Engineering of Piping Systems

Detailed engineering involves design, detail, engineering and layout of piping…