Plant Design & Engineering with AVEVA E3D

Technology is crucial in augmenting efficacy and output in dynamic engineering and design. In this era, AVEVA has emerged as the global leader in pioneering computer-aided design (CAD) techniques that support industrial innovation. Among their varied suite of software solutions across engineering, operations, data management, and other streams, Everything3D (E3D) Design is a popular and well-known technologically advanced 3D design solution applicable across process plants, marine, and power industries.

In this blog, we’ll discuss in detail how Rishabh Engineering utilizes AVEVA E3D design, its features, and real-life applications.

How Does the Rishabh Engineering Team Utilize E3D Software?

The Rishabh Engineering team offers plant design with E3D software to optimize design engineering procedures and produce outstanding outcomes to support clients for various projects. Here’s a glimpse at how we utilize E3D:

- Detailed 3D Modeling: Rishabh’s engineers use the extensive modeling features of AVEVA E3D to produce detailed 3D models of machinery, apparatus, instrumentation, and piping systems, thus converting the 3D Model into a highly intelligent 3D model to be utilized for extraction of BOQ’s/MTO, Isometrics for Piping, GAD’s etc

- Clash Detection and Resolution: AVEVA E3D enables our team to find and fix conflicts between various discipline-specific elements. This involves pipes, structural components, and equipment collisions, ensuring that everything fits together perfectly and preventing expensive rework during the construction phase.

- Design Optimization: The software allows our engineers to locate areas for improvement and improve the design to achieve project objectives more effectively by modeling various design scenarios and evaluating their effects.

- Enhanced Visualization: With AVEVA E3D’s enhanced visualization features, Rishabh Engineering may virtually walk through projects and render them lifelike. These visual aids help clients and stakeholders better understand the design and discipline-specific elements, making communication and decision-making easier during the project.

- Collaborative Work Environment: Despite team members’ locations, the program offers a central hub for collaboration, enabling them to work together in real time. This allows everyone to work with the most recent data and encourages collaboration within interdisciplinary teams.

- Integration with Other Systems: Rishabh Engineering may increase productivity and streamline processes by using AVEVA E3D’s smooth integration with other engineering tools and systems. From design and engineering to procurement and construction, this integration guarantees data coherence and consistency throughout the project.

- Compliance and Documentation: The software helps ensure compliance with industry codes, norms, and regulations by offering options for monitoring and documentation. The engineers at Rishabh can extract precise deliverables, such as specifications, reports, and drawings, to show that they comply with the necessary codes and standards in line with client requirements.

- Training and Support: Rishabh Engineering invests in training and support for its team members to maximize the benefits of AVEVA E3D. This includes initial training sessions to familiarize engineers – designers & database Administrators with the software and ongoing support to address any technical issues or challenges that may arise during project execution.

What is AVEVA E3D Design?

AVEVA created the advanced 3D modeling and design software solution AVEVA E3D Design, especially for the engineering and construction sectors. It functions as a cohesive platform for engineering and design that promotes teamwork, expedites procedures, and enhances project implementation.

Applications of E3D Plant Design Software

- Plant Design: The petrochemical, chemical, and oil and gas (O & G) sectors all extensively use AVEVA E3D Design for plant design. It helps to create intricate process plants accurately and efficiently.

- Shipbuilding/Offshore Platforms & FPSO: Shipbuilders rely on AVEVA Marine to design ships (Hull Side), optimize layouts, and guarantee adherence to international standards. The software’s capacity to manage complex and sizable ship designs is especially useful. AVEVA E3D Design is also widely used on offshore O & G exploration and production platforms along with FPSO topside. Rishabh has extensively utilized AVEVA E3D Design suits to help clients reconstruct/modify and newly built FPSO topside projects, helping clients optimize modular construction.

- Infrastructure Development: AVEVA E3D Design helps create precise structural models for civil engineering projects, including bridges, tunnels, and airports. This improves project coordination and visualization.

- Manufacturing: Production facility design and workflow optimization are two areas where manufacturers apply software. The ability to model in 3D facilitates the creation of effective industrial layouts.

Benefits of E3D Plant Design Software

Organizations can benefit greatly from implementing AVEVA E3D Design in several ways.

- Enhanced Productivity: Project completion is accelerated through streamlined processes and teamwork.

- Saved costs: Throughout the project, fewer mistakes and reworks equal saved costs. Interoperability with external software helps migrate/integrate with the AVEVA E3D platform.

- Enhanced Accuracy: The software’s accuracy increases design accuracy and guarantees compliance with industry standards.

- Improved Imagery: Decision-making and stakeholder communication are aided by improved visualization.

- Scalability: AVEVA E3D Design is scalable enough to accommodate the requirements of projects of varying sizes, including transfers and metering skids, modular refining and chemical complexes, and FPSO topside and offshore platforms

Real-Life Use Cases of Plant Design With E3D from Rishabh Engineering Experience

The Rishabh Engineering team has been at the forefront of utilizing AVEVA E3D Design, which helps with this.

- Engineering Cost Optimization

- Simplifying Procurement Support by Automating BOQ Extraction

- Ease of Working

Listed below are some of the most prominent project cases where E3D helped us significantly.

Case 1:

Client Profile: An American multinational energy corporation engaged in every aspect of the oil and natural gas sector.

Scope: FEED & Detailed engineering of Production Modules on Topside FPSO project located in West Africa.

Technical Specifications:

- Steel Tonnage Handled: 3433 Tons

- No of lines (Flange Type Handled): 10000

- Total no of lines: 247

- Critical lines identified for Piping Stress Analysis: 101

- Temperature & Pressure: Max. Design Pressure 551.7 bar(g) & Max. design Temp. 198.8 deg. C, Rating-10000

- Name of the modules: 7S (Essential Generator Set), 4P (Gas Metering Unit) & 3P (Sea Water Injection)

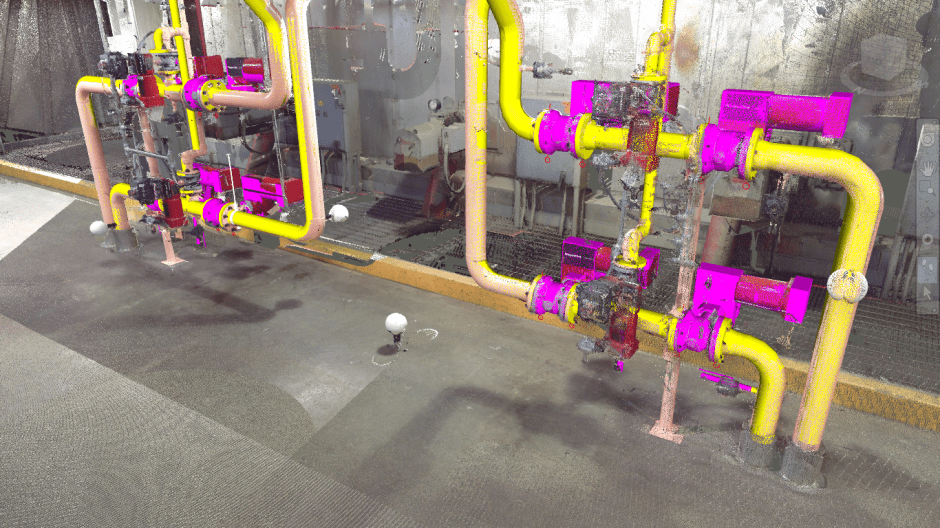

Scenario 1: How did Rishabh Engineering help the client optimize cost by utilizing AVEVA E3D?

Challenge Encountered:

- Integration of laser scan data to a 3D modeling tool

- Cost Control

- Managing project schedule & timeline

CASE A: Additional cost on Light Form Modeler (LFM) Server licensing: The integration process may necessitate additional expenses in terms of licensing for the LFM server with another 3D modeling tool, which poses a significant cost consideration.

CASE B: Additional effort with loss of productivity: Implementing the integration may require additional effort from the team, potentially leading to a loss of productivity. Balancing this extra effort with maintaining project momentum becomes crucial.

Concurrently, we must navigate the challenge of managing project schedules and timelines amidst the integration process. Ensuring that the integration does not cause delays or disruptions to the overall project timeline is paramount for meeting project deadlines and stakeholder expectations.

Rishabh Solution: We utilized AVEVA E3D over other 3D modeling products to convert scan data to an LFD file. This one-month effort saved significant time and cost while aligning with the project schedule.

Results Achieved:

- COST: 7% saving on engineering project costs by utilizing the E3D platform

- TIME: Engineering efforts by 9 -10 months

Scenario 2: Automation and Customization of BOQ Extraction for Seamless Procurement Support

Challenge Encountered: Navigating procurement scheduling poses difficulties due to the limited visibility inherent in conventional Bill of Quantities (BOQ) formats. With inadequate insights, planning becomes cumbersome, potentially leading to delays and inefficiencies. Addressing this challenge requires innovative solutions to enhance visibility and streamline procurement processes effectively within a constrained framework.

Rishabh Solution: We created a customized database in accordance with client requirements (mutually agreed format) in a specified BOQ format for their procurement needs.

Results Achieved:

- 20% time saving, ~100% accuracy with optimal quality standards

- Negligible Data Loss

- ~100% customized data centralization as value addition

Scenario 3: Ease of Working While Handling/Managing Large & Standardized Database Volume

Challenge Encountered: Most popular 3D modeling tools struggle with the limited capability to handle large and standardized database volumes effectively. This constraint hampers efficient management of extensive datasets, posing significant scalability and standardization challenges. Overcoming this hurdle requires innovative solutions to enhance database capabilities and ensure seamless handling of voluminous, standardized data.

Rishabh Solution: E3D helped seamlessly manage a huge database volume while ensuring data standardization protocols.

Results Achieved:

- Saved 2x time on database management while adhering to the optimal schedule and quality

Case 2:

Client Profile: Asia-based leading Indian manufacturer of specialty chemicals and pharmaceuticals

Scope: Brownfield chemical plant expansion project (Buss IV)

Technical Specifications:

- Steel Tonnage Handled: 250 tons

- No of lines: 201

- Critical lines for Pipe Flexibility Analysis: 46

Scenario 1: How did Rishabh Engineering help the client with effort optimization & deliver accuracy?

Case 1: Interoperability between AVEVA E3D & Trimble TEKLA

Challenges Encountered: Integrating other 3D modeling software with TEKLA for review poses hurdles. Balancing both tools demands additional effort, risking productivity. Ensuring accuracy in the output generated became a paramount concern, raising challenges in maintaining precision throughout the project lifecycle. Efficiently managing these complexities is crucial for seamless integration and project success.

Rishabh Solution: We utilized E3D as a one-source tool to export the TEKLA model and compare, review, and modify the structural design.

Results Achieved:

- Helped save 30% efforts on correlation and correction efforts.

- ~100% accuracy with model deliverables to help keep up with the project timeline.

Our specialization extends beyond technical skills as our teams deeply understand client needs to deliver value beyond cost, time, and quality.

Final Words

In conclusion, technology is pivotal in enhancing efficiency and productivity in engineering and design. AVEVA stands out as a global leader, particularly with its AVEVA E3D Design software, renowned for its advanced 3D modeling capabilities across various industries. Rishabh Engineering’s 3D CAD Modeling Services team effectively leverages this technology to streamline design processes, ensure accuracy, and optimize project outcomes. By employing E3D, they overcome challenges such as cost control, schedule management, and interoperability with other software like TEKLA. Our team consistently delivers outstanding results through innovative solutions and a commitment to excellence, driving success in complex engineering projects.

Ready to optimize your plant engineering projects?

Explore how our team harnesses AVEVA E3D for precise results and efficiency in revolutionizing your engineering projects.

Related Blogs

Related Blogs

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…