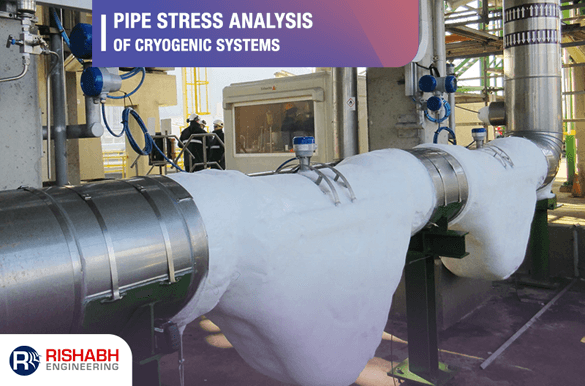

Piping Stress Analysis For Cryogenic Systems

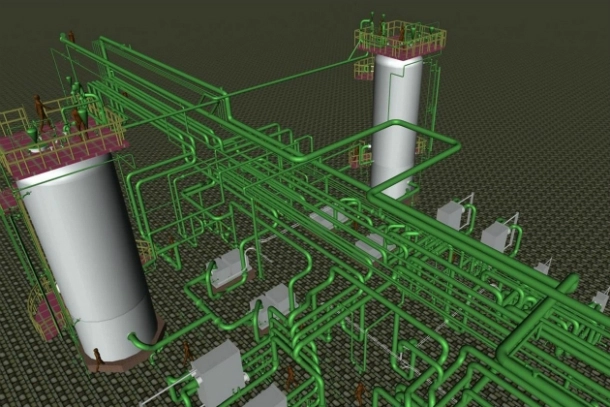

Cryogenic piping systems are used in a range of industrial applications including LNG transport, storage and regasification, Hydrogen storage and transport and the food and beverage sector. They must be designed to withstand operational stresses and displacements while also regulating thermal forces. Therefore, it is important to take into consideration factors like flexibility in the layout of the piping system and support locations.

What is Cryogenic Piping?

It refers to the piping systems that are used in a wide range of industrial applications that require extremely low temperature often below -300°F (-150° C) or lower. It also faces the unique problem of water condensation on insulation. If the moisture permeates insulation, it condenses that significantly increases the likelihood of corrosion in the lines. And therefore these systems face corrosion and deterioration challenges.

It is also referred to as cold piping/cold insulated piping with industrial application across;

- Liquid natural gas (LNG) transportation

- Regasification process

- Liquid Hydrogen / Nitrogen storage and transportation

Basics of Cryogenics Piping

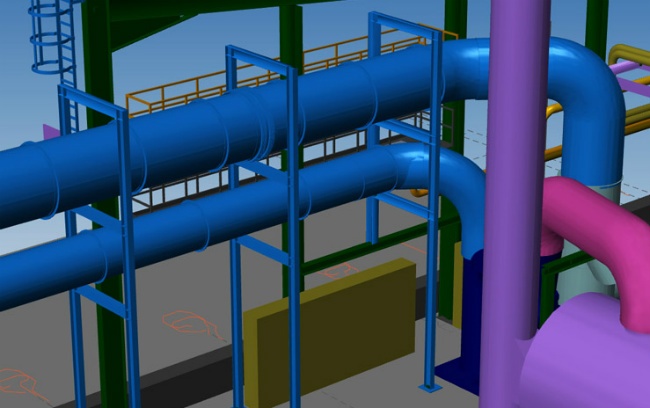

- There are two pipes concentric to each other supported by internal guides/spiders.

- The core pipe is at cryogenic temperature and the Jacket is vacuum normally at ambient temperature. Cryogenic temperature is generally -300F (150C) or lower.

- In some cases, there is also containment piping wherein the Jacket will also see pressure (instead of Vacuum) same as that of core pipe.

- Cryogenics piping is used in transporting/storing cryogenics fluids such as Liquid Oxygen (LOX), Liquid Nitrogen (LN2/LNG), Liquid Hydrogen (LH2).

Future of Cryogenics

- LNG demand is expected to increase from today’s 13% to 23% by 2050. LNG is used across the residential, commercial & industrial sectors as diverse as heating, cooking, generating electricity and manufacturing a wide variety of products.

- LH2 is considered as future fuel and its demand is going to increase gradually.

- LOX is in great demand today considering the requirement of oxygen in the COVID-19 situation. New plants are being set up in a short time to meet the demand.

To maintain the safety and integrity of these systems it is crucial to anticipate and overcome these challenges.

Essentials of Pipe Stress Analysis (PSA) of Cryogenic Vacuum Jacketed Piping

Vacuum Jacketed Pipe (VJP) also known as Vacuum Insulated Piping (VIP) is the preferred piping solution for the safe, reliable, cost-effective transfer of cryogenic liquids. It is the most cost-effective way to transfer cryogenic liquids.

Here are a few considerations;

- Cryogenic lines are critical in the analysis as two pipes having different displacements are to be considered connected. The core being at cryogenics temperature – contracts and Jacket being at a temperature bit higher than ambient – expands.

- Max load capacity for internal guides is derived through FEA using Ansys.

- Field weld joints are checked for welding strength to take care of axial loads.

- Internal guides are placed close enough to maintain the concentricity of pipes.

- External supports (Primary supports) types and locations are selected as per the analysis.

Challenges in PSA of Cryogenic VJ Piping

- To accommodate the differential contraction is due to core pipe contraction and jacket expansion.

- If using Expansion joints, it will have an axial contraction/expansion limit which is to be taken care of while analyzing. Lateral displacement of expansion joints should be minimum. Thrust force due to expansion joints is very critical at bends and has to be taken care of.

- Expansion joints will create an adverse effect in sustain stresses because of pressure thrust at bends and the change of direction. Internal guide loads should be within the allowable loads. It should be designed considering that it should not exceed the load limit.

In addition to this, the flexibility requirement analysis of Cryogenic systems is somewhat complicated and there are many other challenges. Do take a look at some of the challenges in cryogenics piping stress analysis while working with cryogenic systems.

Use Case:

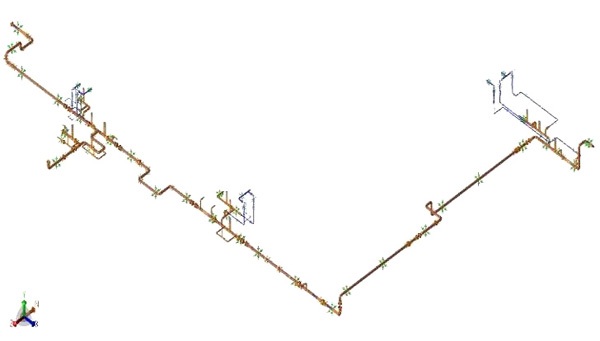

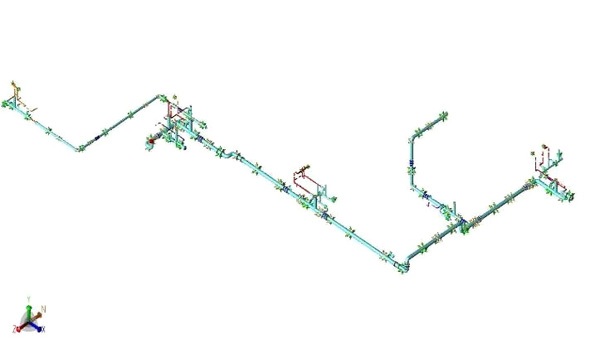

Project Overview: Pipe Stress Analysis of Vacuum Jacketed Cryo lines P12 19

Project Overview and Challenges:

- Conservative analysis approach. (i.e., High Design Temperature and pressure as compared to Operating Temperature and pressure). Used axial bellows to absorb the contraction and to reduce the differential displacement between core and jacket.

- High temperature and pressure line caused failure in small bore tapping in expansion case (used ASME31J or re-route tapping branch).

- Internal guides between core and jacket are used to maintain the concentricity of the core and jacket pipe. – Challenging was to qualify internal guide within the allowable load.

- In the long run pipe axial displacement on the elbow was more, so to avoid it we have used cone-type philosophy which will indirectly connect the core and jacket and thus reduce the differential displacement.

- To qualify VJ valve due to long actuator height which caused failure in expansion case.

- Qualification of system with less nozzle allowable load or high displacement.

- Performed FEA for Internal guide and to get the stiffness of heat bridge.

Man-Hours: ~ 3000

Schedule: 6 Months

Deliverables:

- C-II model

- Marked-up Isometrics

- Piping stress analysis report including weld strength check

| Parameter | Value |

|---|---|

| Total Piping Systems | 15 |

| Total Number of Lines | 50 |

| Max. Pipe Diameter | 6” (Core), 8” (Jacket) |

| Max. Temperature | -258° C |

| Max. Pressure | 44 N/mm² |

Cryogenic piping lines are a special case where the operating temperature and installed ambient temperatures are so different. Rishabh helps create a jacketed pipe with cryogenic insulation for liquefied Nitrogen, Oxygen, Argon, Helium, Natural Gas, Carbon Dioxide, Hydrogen & LNG — from storage tanks to the final use point. With Design and Stress Analysis of Cryogenic Piping Systems, our projects are usually led by a senior stress engineer trained in leading pipe design code, cryogenic safety & VJP project management. As your insulated pipe suppliers, we offer technical assistance with pipe system design, as well as cryogenic valves and cryogenic fittings, regardless of project-level experience. Rishabh Engineering is well-versed and has a collective experience of 2 decades with vacuum jacketed pipe and cryogenic design.

Seek help with cryogenic systems design?

Rishabh Engineering has the required capability and expertise to develop Design and Stress Analysis of Cryogenic Piping Systems

Related Blogs

Related Blogs

Piping Support Design and Engineering

Pipe support design is an important component of piping engineering…

Detailed Engineering of Piping Systems

Detailed engineering involves design, detail, engineering and layout of piping…