Project Information

Detailed Design and Engineering for Chemical Plant

Description

Client

An Asia-based leading chemical manufacturer with facilities spread across continents.

Engineering Requirement

As a provider of detailed engineering and design services, Rishabh Engineering was appointed to carry out detailed engineering for their chemical plant along with the submission of the associated drawings by complying to required standards & specifications.

The overall scope for this project included;

- Project setup and administration activity

- Preparation of Final P&IDs and PMS from basic client’s P&ID

- Preparation of Line List

- Equipment and Piping model based on P&ID and client’s guidelines

- 50# and 120# Steam line routing based on given analysis report and native file by the client

- Slab Design calculation and floor wise slab drawing

- Structure Modeling based on received drawing from client

- Modeling of duct/chute and space allocation of packages/machines

- Modeling of piping support as per support standard approved from client

- Instrumentation and electrical Cable Tray routing for more than 100 mm as per given inputs by client

- Model for firefighting to be prepared by Rishabh based on client guidelines and philosophy

- Support Standard for Metallic and Non-Metallic Pipes as per client’s guidelines

- Prepare 5 stages Piping MTO

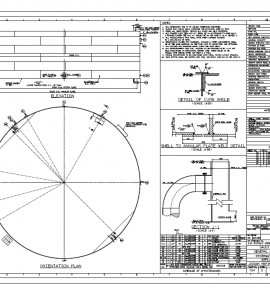

- Prepare Equipment Nozzle Orientation and Elevation sketches from vendor Input

- Preparation of mechanical pipe support (MPS)/ special pipe support (SPS) as per requirement and also submit sketches to client for Civil Work

- Preparation of different 3D Isometrics drawings view – service wise for erection purpose as per requirement

- IFA and IFC isometric submission as per approved checklist

- Preparation of Piping GAD

Additional Scope;

- As-built of P&IDs

Want to know more about this project?

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 8511122697

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent blogs

In this blog, we’ll explore the frequently used equipment P&ID symbols, while explaining their function, significance, and how they contribute to effective system design.

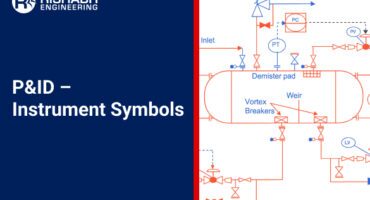

This blog will dive deep into P&ID instrument symbols, explaining what they are, their importance, components, the types of symbols used, and how to interpret them and how Rishabh Engineering integrates these standards to ensure efficient, safe, and compliant designs for process systems.

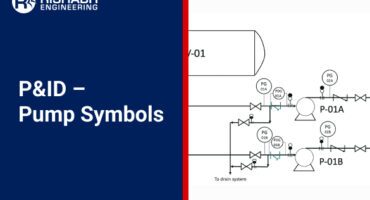

This blog takes a deep dive into P&ID pump symbols — what they are, how they are used, why they are important, how to read and interpret them along with guidelines and best practices for creation. For engineers, designers, and operators alike, understanding pump symbols is critical to both interpreting and developing process designs that are safe, functional, and compliant with industry standards.