Project Information

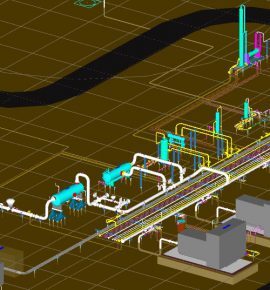

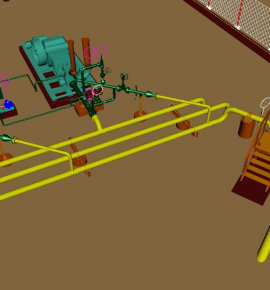

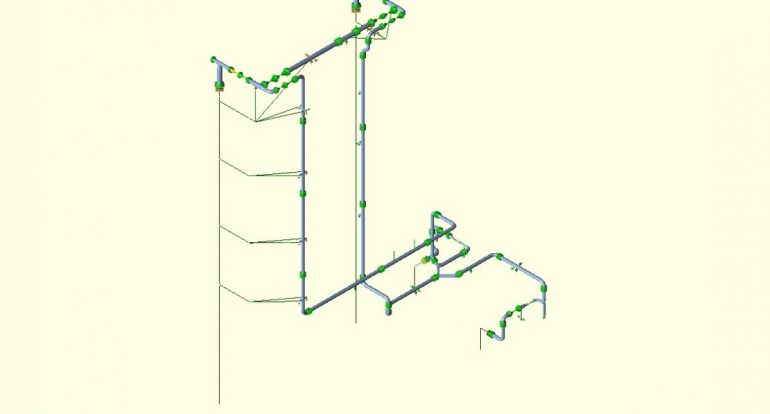

Pipe Stress Analysis & support node number marking for the Glycol Piping System using CAESAR II

Description

Client

A privately held multi-discipline engineering, procurement and construction management organization who have developed and maintained a reputation in the chemical, petrochemical, refining, paper, power, industrial power/cogeneration, gas and liquid transmission, manufacturing and fabrication industries.

Engineering Requirement

- Piping Stress Analysis

Delivered

- Stress Analysis for the Glycol Piping System

- Stress isometrics with support node number markup

- ASME B31.3 codes and standards were followed to ensure higher quality in delivering Piping Stress Analysis

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent Blogs

In the complex world of process industries, effective communication and documentation are crucial for ensuring safety, efficiency, and successful operation. The Piping and Instrumentation Diagram (P&ID) is vital in this domain. With this article, we will explore what is P&ID, its significance across diverse industries, the symbols employed, and a comprehensive guide on crafting them.

In this blog, we’ll explore the frequently used equipment P&ID symbols, while explaining their function, significance, and how they contribute to effective system design.

This blog will dive deep into P&ID instrument symbols, explaining what they are, their importance, components, the types of symbols used, and how to interpret them and how Rishabh Engineering integrates these standards to ensure efficient, safe, and compliant designs for process systems.