Project Information

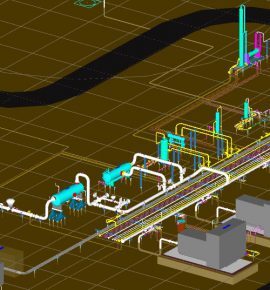

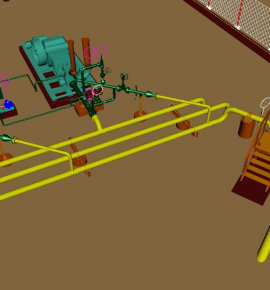

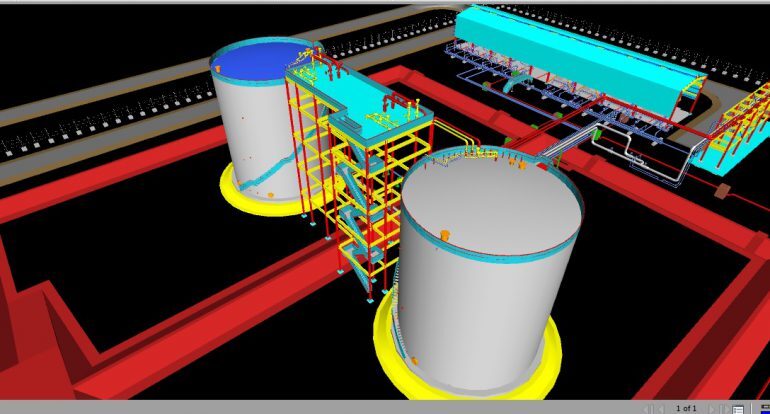

3D Modeling of Onshore Operational Oil Plant

Description

Client

A Dubai-based diversified multinational group who operates in the areas of engineering and construction, infrastructure development and management, exploration of hydrocarbons, and mining of minerals/metals for the energy sector.

Engineering Requirement

For the below requirements, the client needed 3D Modeling using PDS,

Equipment modeling

- Vessels

- Flow Suction Tank

- Pumps

- Launcher / Receiver

- Glycol Regeneration Unit

- Manifolds

- Piping modeling

Packages

- Tank Flare Package

- HP Flare Package

- Oil Export Fiscal Package

- Biocide Injection Package

- Glycol Regeneration Unit

- Effluent Water Treatment Package

Structure

- Pipe rack, sleepers

- Crane, Fence

- Platform

- Skid

Civil

- Road Modeling (Existing, Gatch, Asphalt)

- Pump house Foundation

Delivered

- Effective on-time delivery of committed 3D Models

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent Blogs

In this blog, we’ll explore the frequently used equipment P&ID symbols, while explaining their function, significance, and how they contribute to effective system design.

This blog will dive deep into P&ID instrument symbols, explaining what they are, their importance, components, the types of symbols used, and how to interpret them and how Rishabh Engineering integrates these standards to ensure efficient, safe, and compliant designs for process systems.

This blog takes a deep dive into P&ID pump symbols — what they are, how they are used, why they are important, how to read and interpret them along with guidelines and best practices for creation. For engineers, designers, and operators alike, understanding pump symbols is critical to both interpreting and developing process designs that are safe, functional, and compliant with industry standards.