Project Information

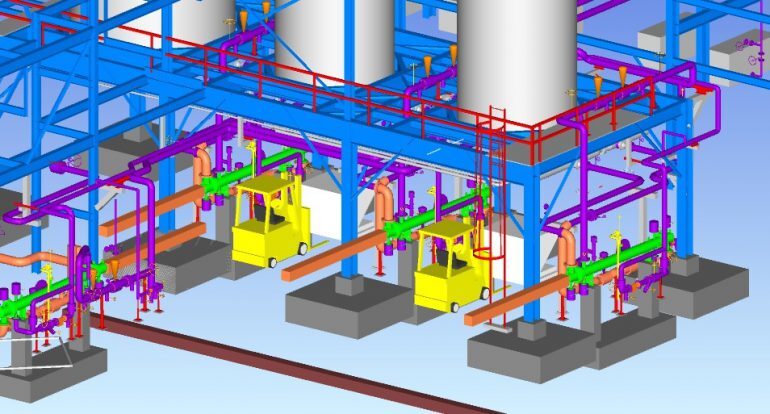

Multi-discipline Engineering for Reactor Area of ACE Plant

Description

Client

A privately held multi-discipline engineering, procurement and construction management company. They operate in industries like petrochemical, refining, paper, power, industrial power/cogeneration, gas transmission, manufacturing and fabrication.

Client Testimonial

“The detailed engineering design and 3D model developed by Rishabh Engineering met the inputs given by us, and we had an excellent model review meeting with our end client dealing in chemical engineering and processing.”

– Project Manager

Engineering Requirement

- Multidiscipline engineering for the reactor area of ACE (Acetylenics Complex) plant including civil & structural engineering, pipe stress analysis, electrical & instrumentation and piping engineering

- Plant’s direct steam injectors to be replaced with 4 shell and tube heat exchangers

Delivered

- Equipment GA Drawings

- Visual Stress Analysis reports

- Equipment Foundation Drawings

- Special Support drawings

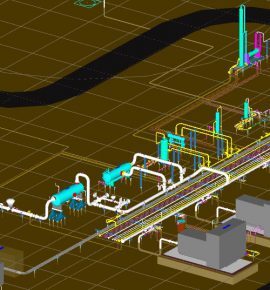

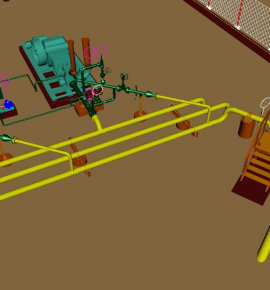

- 3D Model on PDS

- Instrument Datasheets

- Isometrics Drawings

- I.E. ASME B31.3 codes and standards were followed to ensure high quality of delivery

Want to know more about this project?

Our Recent Projects

Connect with us for all your engineering design needs

US Toll-Free Phone

+1-877-747-4224

India Phone

+91 (265) 2680159

Drop Us An Email

sales@rishabheng.com

Our Offices

USA, UK & India (Head office)

Ready to work with us? Tell us more

Our Recent Blogs

Finding tools that simplify and improve the accuracy of the design and analysis process is crucial when selecting the best structural engineering software. Engineers can work more quickly, with limited to no errors, while building sturdy, secure structures with the aid of the leading software. We'll examine some of the best choices that can elevate your efforts in this part.

In this article, we explore the fundamental role of process engineering in petrochemical industry and how Rishabh Engineering’s process engineering discipline experience helps companies meet the ever-evolving challenges of the sector.

In this blog, we’ll discuss the specifics of coal gasification plant design, including components, considerations, benefits along with potential challenges and how Rishabh Engineering can help solve them with multidiscipline design engineering.