Understanding P&ID Instrumentation Symbols

Piping and Instrumentation Diagrams (P&IDs) are essential tools for visualizing and communicating the design, configuration, and operation of diverse systems in process engineering projects nowadays, as you would agree. The instrumentation and control devices in a process system are mostly represented by P&ID instrumentation symbols. Their visual shorthand enables engineers and operators to decipher system behavior, solve problems, and guarantee seamless operation.

This blog will dive deep into P&ID instrument symbols, explaining what they are, their importance, components, the types of symbols used, and how to interpret them and how Rishabh Engineering integrates these standards to ensure efficient, safe, and compliant designs for process systems.

What Are P&ID Instrumentation Symbols?

P&ID instrument symbols represent the devices used in process control systems. These devices measure, control, and monitor process variables like pressure, temperature, flow, level, and others.

The instrumentation symbols in P&ID diagram are standardized graphical representations, often based on widely recognized codes such as ISA-5.1 (International Society of Automation), ISO 14617, or IEC standards.

P&ID instrument symbols serve several important purposes:

- Communication: By providing a clear, unambiguous picture of instruments and their link to the system, they help engineers, operators, and maintenance teams communicate effectively.

- Clarity in Design: Instrumentation symbols help identify possible areas for improvements or modifications by specifying how the control system will communicate with the process.

- Troubleshooting: Because technicians can easily find and comprehend the purpose of each instrument thanks to standardized symbols, diagnosing issues with control systems is made simpler.

- Compliance: The P&ID complies with industry best practices and safety laws thanks to adherence to international standards.

Types Of P&ID Instrument Symbols

There are several categories of instrumentation symbols in P&IDs, each representing different devices and control components.

These instrument symbols can be grouped for identification as follows:

1. Measurement Instruments:

These devices are used to measure process variables such as pressure, flow, temperature, and level.

Common examples include:

- Pressure Transmitter (PT): Often represented as a circle with the letters “PT” inside. This symbol is used to measure the pressure in a pipeline or vessel.

- Flow Transmitter (FT): Typically represented by a circle with the letters “FT.” These devices measure the flow rate of liquids or gases in pipes.

- Temperature Transmitter (TT): Represented by a circle and “TT” to indicate a temperature-sensing device.

- Level Transmitter (LT): These symbols are used to measure the level of liquid or solid within a container, tank, or vessel.

2. Control Valves:

They help regulate the flow of fluids in a process system by responding to control signals. Common control valve symbols include:

- Control Valve (CV): Represented by a circle with the letters “CV” and often a line to indicate valve position. Control valves are used in a wide range of industries to control flow, pressure, and temperature.

- Safety Relief Valve (SRV): A symbol that shows a spring-loaded valve designed to open at a preset pressure to protect the system.

3. Flow Control Devices:

These devices maintain and regulate flow within a process. These symbols are critical in ensuring optimal flow rates for various applications:

- Flow Controller (FC): A circle with “FC” indicates a flow control device that regulates the flow of a fluid to maintain a set point.

- Flow Switch (FS): A symbol representing a device that detects if the flow of a substance exceeds or falls below a threshold and sends an alert or triggers an action.

4. On/Off Control Devices:

These symbols represent devices used for turning operations on or off. They often include:

- On/Off Valve (V): A basic valve symbol used to isolate or shut off flow in a pipe or process.

- Motor-Operated Valve (MOV): A valve that is operated by a motor, typically represented by a circle with an “M” inside to denote motor operation.

5. Sensors and Detectors:

These instruments are designed to detect specific process conditions. Some common examples include:

- Pressure Sensor (PS): The symbol for pressure sensors is a circle with “PS” inside. These devices detect and measure the pressure in systems to prevent over-pressurization.

- Temperature Sensor (TS): Represented by a circle with “TS” to denote a temperature-sensing device in a system.

6. Safety and Protection Instruments:

These devices are designed to protect the process from unsafe conditions, preventing accidents and ensuring the system operates within safety limits:

- Pressure Relief Valve (PRV): A safety valve used to relieve excess pressure, represented by a circle with the “PRV” symbol.

- Flame Arrestor (FA): A device designed to stop flames from propagating, typically shown as a “FA” symbol.

7. Other Control Devices:

- Differential Pressure Transmitter (DPT): Measures the difference in pressure between two points in a system, represented by a circle with “DPT” inside.

- Relay (R): A symbol for an electrical relay used in control systems, often shown with a circle and the letter “R.”

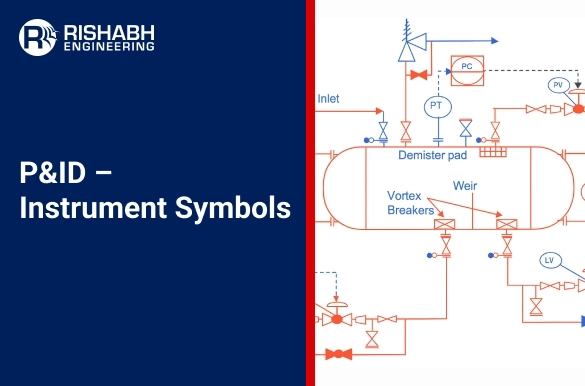

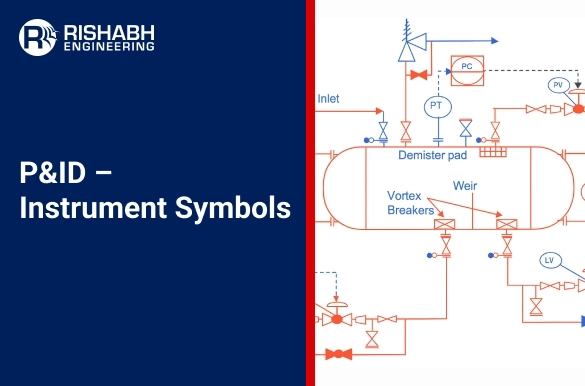

P&ID – Instrumentation Symbols

They show how many different tools are utilized to measure, track, and manage process variables in a plant. Every symbol serves as a visual abbreviation for the function of the device, be it monitoring temperature, pressure, flow, level, or automation and safety. Every sign, from recorders, control valves, and safety devices to transmitters, sensors, and controllers, conforms to defined conventions such as ISA or ISO. Tags, loop indications, and connection types are frequently used in these notations to draw attention to integration points and control logic. Engineers and operators can more effectively design, run, and troubleshoot complicated systems when they use accurate instrumentation symbols.

Now let’s explore the detailed representation of instrumentation P&ID symbols that we consider;

Analyzer Transmitter: Measures and transmits analysis results remotely.

Computer Indicator: Displays digital information from measurement devices.

Flow Controller: Regulates flow rate within the system.

Flow Element: Detects flow in pipes or channels.

Flow Indicator: Visually shows flow rate information.

Flow Recorder: Records and logs flow rate data.

Flow Transmitter: Converts flow data to electrical signals.

Indicator 1: Displays first measurement parameter visually.

Indicator 2: Displays second measurement parameter visually.

Indicator 3: Displays third measurement parameter visually.

Indicator 4: Displays fourth measurement parameter visually.

Indicator 5: Displays fifth measurement parameter visually.

Level Alarm: Signals when level exceeds preset limits.

Level Controller: Regulates fluid levels within specified range.

Level Gauge: Provides visual indication of fluid levels.

Level Indicator: Displays real-time fluid level information.

Level Recorder: Logs fluid level data over time.

Level Transmitter: Converts fluid level readings to signals.

Pressure Controller: Maintains pressure within specified limits.

Pressure Indicating: Displays current pressure value visually.

Pressure Recorder: Logs and records pressure measurements over time.

Pressure Recording: Captures and documents pressure changes continually.

Pressure Transmitter: Sends pressure data as electrical signal.

Programmable Indicator: Customizable display for various process parameters.

Shared Indicator 1: Displays shared process measurement visually.

Shared Indicator 2: Displays additional shared process measurement.

Temp Controller: Maintains temperature within desired range.

Temp Indicator: Displays temperature readings visually in real-time.

Temp Recorder: Logs and tracks temperature over time.

Temp Transmitter: Converts temperature data to electrical signals.

Temperature Element: Detects temperature in process or equipment.

Transducer: Converts physical measurement into electrical signal.

Components Of P&ID Instrumentation Symbols

Each P&ID instrument symbol typically contains several key components to convey essential information:

1. Function Code: It specifies the role of the instrument in the system (e.g., measurement, control, safety). Common function codes include:

- M for measurement

- C for control

- S for safety

- T for temperature

- P for pressure

2. Tag Number: It is a unique identification number assigned to each instrument. For example, FT-101 would represent a flow transmitter with the tag number 101.

3. Indicating and Recording Devices: Some symbols may include indicators or recorders that display the real-time status of the process variable or record data for analysis.

4. Connection Types: Lines between symbols indicate how devices are interconnected. These can represent pneumatic, electrical, or hydraulic connections, depending on the control system’s design.

How to Read P&ID Instrument Symbols?

Reading P&ID symbols for instrumentation discipline requires an understanding of the functional role of each device in the system.

Here are a few steps to help interpret P&ID diagrams effectively:

- Determine the Process Flow: It’s critical to comprehend how materials move through the system. Arrows are frequently used to show the direction of the flow, and the flow path will link different instrumentation symbols.

- Recognize the Purpose of Every Symbol: Every symbol stands for a certain purpose, such as safety, control, or measurement. You can interpret each symbol’s function in the system if you know what it stands for.

- Look for Control Loops: A lot of P&ID diagrams depict control loops, in which controllers use data from measuring devices to modify flow, pressure, or other process parameters.

- Take Note of Tag Numbers: Every instrument will have a distinct tag number that enables you to compare it with specifications or data sheets for further in-depth details.

Final Words

The design, operation, and purpose of instrumentation and control systems in industrial processes are all represented by P&ID instrumentation symbols. A thorough comprehension of these symbols guarantees adherence to industry standards, facilitates design and debugging, and encourages effective communication. Our instrumentation & control engineering services at Rishabh Engineering include accurate and thorough P&ID designs that are customized to your project’s requirements. We provide solutions that are optimized for operational reliability, efficiency, and safety using a multidisciplinary approach. Our expertise makes it possible for you to use precise, standardized P&ID instrument symbols for smooth operations and reliable process control, whether you’re creating a new process or maintaining an old system.

Need Support For P&ID Instrumentation Symbols?

Partner with Rishabh Engineering team for precise, compliant, and efficient P&ID designs that ensure optimal system performance and safety.

Related Blogs

Related Blogs

Best Structural Engineering Software for Accurate Analysis

Finding tools that simplify and improve the accuracy of the…

Detailed Engineering Considerations for Project Success

Engineering projects today require meticulous planning and execution across various…