FEED vs Detailed Engineering: Key Deliverables Explained

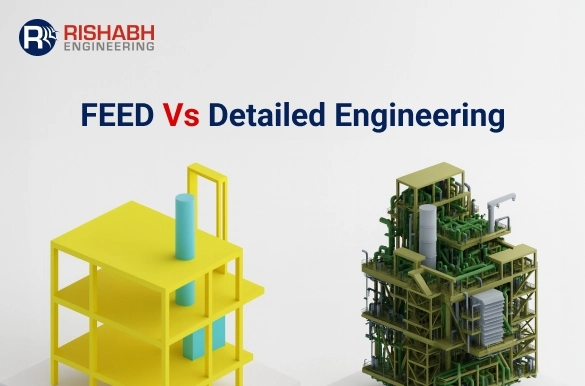

Front-End Engineering Design (FEED) and Detailed Engineering are two of the most crucial phases in the lifecycle of any industrial project. Together, they provide the technical foundation and execution roadmap needed to transform a project from concept to reality. While FEED focuses on defining project scope, feasibility, cost estimates, and risk mitigation strategies, Detailed Engineering builds on that groundwork by developing precise drawings, specifications, and construction-ready documentation. These stages ensure alignment across all engineering disciplines—mechanical, civil, structural, electrical, instrumentation, and process—promoting seamless coordination and reducing costly changes later. By learning the key differences between FEED and Detailed Engineering organizations can achieve better project control, improved safety and compliance, and greater efficiency in procurement, construction, and commissioning.

This blog explores the role, purpose, importance, and key deliverables of FEED vs detailed engineering for ensuring success in industrial engineering projects.

FEED Vs Detailed Engineering – Key Differentiators

What is Front End Engineering and Design?

FEED, or front-end loading (FEL), is a critical stage in the development of large-scale industrial projects. This phase focuses on establishing the project’s technical and specific needs to ensure a solid foundation for the detailed design and implementation that follows. The goal of FEED is to reduce risks, optimize costs, and confirm the project’s feasibility before moving into detailed engineering. Read this blog to learn more about front end engineering design.

What is the Purpose of Front-End Engineering Design?

It helps lay a strong foundation for a project before moving into detailed design and construction. It ensures that the project is viable, functional, and set up for success by thoroughly understanding its scope, technical needs, costs, and potential risks. Essentially, it bridges the gap between the initial idea and the actual execution, helping to minimize risks and improve the likelihood of success.

Here’s a clearer breakdown:

- Scope Definition: It defines the project’s overall scope, including its goals, technical requirements, and performance standards.

- Design Basis: It sets the groundwork for all future design work by clearly outlining the design basis.

- Process Design: It helps finalize the process design, which includes creating Process Flow Diagrams (PFDs), Piping and Instrumentation Diagrams (P&IDs), and heat and material balances (H&MBs).

- Equipment Selection: Major equipment is identified and specified during FEED, including creating data sheets and preliminary 2D/3D models.

- Cost Estimation: A detailed cost estimate is developed, which will be used for budget approvals and act as a baseline for cost control throughout the project.

- Safety and Environmental Considerations: FEED addresses safety concerns and environmental impact, including hazard assessments (such as HAZOP studies) and environmental impact evaluations.

- Procurement Planning: It sets the stage for procurement by identifying critical materials and equipment and outlines a supply chain management plan.

- Project Schedule: FEED also helps define the overall project timeline and execution plan, ensuring smooth progress moving forward.

Importance of FEED

It is essential for bringing all disciplines together from the beginning of multidisciplinary engineering projects, where teams from mechanical, civil, structural, electrical, instrumentation, piping, and process engineering collaborate. This is why it’s so important:

- Defines Clear Project Scope Across Disciplines: Helps establish a well-defined project scope, ensuring all engineering teams are aligned from the beginning. This prevents scope creep and ensures each discipline knows its responsibilities and interfaces with others.

- Facilitates Design Integration: Multidisciplinary projects involve complex interdependencies, and FEED allows time for integration planning — making sure, for example, that piping routes don’t clash with cable trays, or that structural supports are sized correctly for equipment loads.

- Enables Accurate Cost and Time Estimates: By developing preliminary layouts, equipment lists, and material take-offs, it helps estimate budgets and timelines for decision-making, especially in tight time bound EPC and EPCM projects.

- Identifies Risks Early: Allows for early identification of technical, safety, and regulatory risks across engineering disciplines. This helps in planning mitigation strategies before significant investment is made.

- Ensures Compliance with Standards: It ensures that each engineering team follows relevant codes, client specifications, and regional standards from the outset, avoiding costly rework during detailed design or construction.

- Improves Communication and Coordination: Creates a platform for collaborative planning and decision-making. It allows teams to work with a shared understanding of the design intent, reducing miscommunication and siloed decision-making.

- Supports Vendor and Procurement Planning: With defined specifications and preliminary BOMs, procurement teams can start vendor identification, long-lead item planning, and RFQs early reducing delays later in the project.

- Boosts Client Confidence: A robust package shows clients and stakeholders that the project is technically sound and financially feasible, improving trust and facilitating investment approval.

FEED Deliverables

They serve as an overview of the project’s technical and business aspects and are essential in determining the course of action. In addition to enabling precise project planning, budgeting, and risk assessment, these deliverables aid in directing detailed engineering, procurement, and construction (EPC) activity.

Key Deliverables:

- Process Engineering: Includes the foundation for process design, flow diagrams (PFDs), heat and mass balance calculations, a list of all process equipment, and detailed instrument data sheets.

- Equipment Engineering: Covers equipment specifications, mechanical design data sheets, and material requisitions needed for procurement.

- Piping Design: Delivers piping and instrumentation diagrams (P&IDs), specifications for piping materials, and reports from piping stress analysis.

- Instrumentation & Control: Includes specifications for control systems, instrument data sheets, and architectural drawings of the control system layout.

- Electrical Engineering: Provides single-line diagrams, a list of electrical consumers, and technical specifications for electrical equipment.

- Civil & Structural: Encompasses soil investigation requirements, earthwork and foundation drawings, and the structural design approach.

- Safety & Environmental: Includes hazard identification and analysis reports, along with assessments of environmental impact.

- Project Management: Involves the procurement strategy, detailed project timelines, and cost estimation.

- Plot Plan: A general layout showing the positioning of major equipment and structures within the facility.

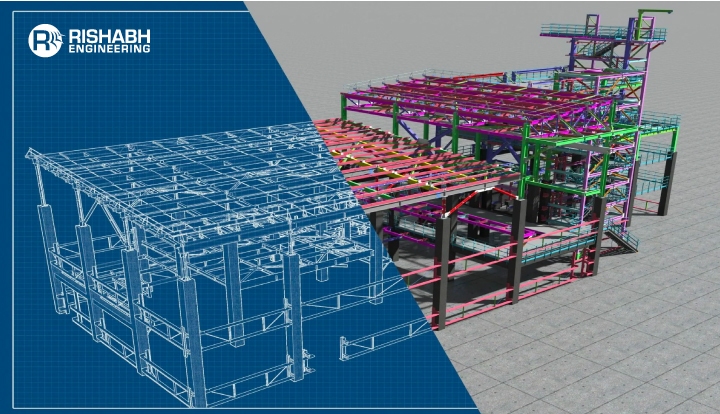

- 3D Model: An early-stage 3D representation of the facility to visualize design and layout.

- Line List: A comprehensive list of all piping lines used across the facility.

- Tie-In List: Detailed documentation of all connection points to existing systems or infrastructure.

What is Detailed Engineering?

It is the last and most comprehensive phase of project planning before real construction starts. From technical drawings and material specifications to pricing projections and construction timelines, every aspect of the project is now well defined. It ensures that the project is completely prepared for procurement, construction, and execution by building on previous phases such as basic engineering and FEED.

Key Elements of Detailed Engineering:

- Precise Drawings and Specs: Engineers create accurate, detailed drawings and specifications for every part of the project — covering all systems, structures, and components.

- Material Quantities and Requirements: They figure out exactly what materials are needed and how much — so there’s no guesswork when it’s time to build.

- Structural Integrity Checks: Structural engineers run in-depth analyses to make sure the design is strong, safe, and up to code.

- Budget and Timeline Planning: Based on the finalized designs, a detailed budget and project schedule are created to guide the entire execution phase.

- Procurement and Construction Planning: The team outlines what needs to be bought, when, and how to do it, including planning the construction process to avoid delays or surprises.

- 3D Modeling and Simulation: Using advanced 3D modeling tools, engineers test the design virtually to catch clashes or issues before construction begins.

- Complete Documentation: Comprehensive documents are prepared, including process flow diagrams, P&IDs (Piping and Instrumentation Diagrams), equipment lists, and construction instructions — making sure everyone involved is on the same page.

Read this blog to learn more about detailed engineering considerations for project success.

What Are the Varied Stages of Detailed Engineering?

This stage involves several crucial processes, such as evaluating and improving the preliminary designs, carrying out intricate technical computations, completing the design of each component and system, and creating the required drawings and documentation. Making sure everything is well-planned and recorded is the aim before proceeding to the following stage, which is often construction and procurement.

Here’s a more detailed breakdown of the stages involved in detailed engineering:

- Reviewing and Improving the Initial Design: At this stage, the preliminary design is carefully examined to spot any issues or areas where it can be improved. Assumptions made earlier are double-checked, and updates are made to ensure the design is practical, accurate, and meets all technical and project requirements.

- Running Calculations and Defining Technical Specs: This step is all about doing math and working out technical details. Engineers calculate everything needed to make sure the design will perform well and remain structurally sound. They also prepare detailed specifications for every part—covering sizes, materials, performance standards, and more. For process industries, this includes creating detailed diagrams like PFDs and P&IDs.

- Finalizing Components and Subsystems: Here, each part of the system—like pumps, valves, or control instruments—is selected and designed in detail. Engineers define how each piece will connect and work with others, ensuring smooth operation when everything comes together.

- Developing Detailed Drawings and Documents: A key output of detailed engineering is a complete set of technical drawings and documents. These include assembly drawings, part drawings, material take-offs, and specifications. This information guides the team during construction or manufacturing, helping them build exactly what was planned.

- Getting Ready for Procurement and Construction: Finally, all the data needed for purchasing materials and equipment is prepared. This includes technical specs, equipment lists, and supplier details. Construction teams are also given the drawings and documents they need to move ahead without delays.

Detailed Engineering Deliverables

They are an extensive collection of documentation, computations, drawings, and specifications created following the FEED phase and used to direct a project’s manufacturing, construction, installation, and commissioning processes. Although these deliverables are discipline-specific, they are coordinated throughout all teams to guarantee constructability, accuracy, and consistency.

The following lists typical Detailed Engineering Deliverables per discipline:

1. Mechanical Engineering Deliverables

- Equipment specifications & datasheets (pumps, compressors, vessels, etc.)

- Equipment GA (General Arrangement) drawings

- Fabrication drawings (vessels, tanks, heat exchangers, etc.)

- Mechanical calculations (thickness, pressure, thermal, etc.)

- Equipment load data

- Vendor data review & integration

- Material requisitions for mechanical items

2. Piping Engineering Deliverables

- Piping & Instrumentation Diagrams (P&IDs) – Final versions

- Plot plans and piping layout drawings

- Isometric drawings

- Pipe support drawings and details

- Piping material specifications (PMS)

- Line list / Line designation table

- Pipe stress analysis reports

- Valve, flange, and fitting datasheets

- Tie-in list and piping MTO (Material Take-Off)

3. Process Engineering Deliverables

- Process flow diagrams (PFDs) – Final updates

- Updated P&IDs

- Process data sheets for all equipment and instruments

- Hydraulic and process simulations

- Line sizing and utility consumption summary

- Control philosophy and operating manuals

- Relief system design and flare load summary

- Heat and material balance (HMB)

4. Civil & Structural Engineering Deliverables

- Structural GA and detail drawings (foundations, pipe racks, platforms)

- Concrete and steel structure design calculations

- Foundation drawings and BOQ

- Soil load data and geotechnical report

- Building layouts (control rooms, substations, etc.)

- Structural fabrication drawings

- Civil works scope and material specifications

5. Electrical Engineering Deliverables

- Single-line diagrams (SLDs)

- Electrical load lists and load calculations

- Cable routing & tray layouts

- Lighting and grounding layouts

- Electrical equipment data sheets

- Substation and switchgear layouts

- Power distribution philosophy

- Earthing and lightning protection plans

- Electrical BOQ and cable schedule

6. Instrumentation & Control Deliverables

- Instrument index and datasheets

- I/O list and control narratives

- Instrument loop diagrams

- Cable block diagrams

- Hook-up drawings

- Instrument location layouts

- DCS/PLC architecture and logic diagrams

- Instrumentation installation drawings

- Material take-off for instruments

7. Safety & Fire Protection Deliverables

- Hazardous area classification drawings

- Firewater system design and layouts

- Fire & gas detection layouts

- Emergency shutdown (ESD) system logic

- Risk assessments (HAZOP, SIL, QRA if applicable)

8. Procurement & Construction Support Deliverables

- Material take-offs (MTOs) for all disciplines

- Technical bid evaluations (TBE)

- Vendor technical document reviews

- Construction work packages (CWPs)

- Erection and installation drawings

- Project specifications and technical standards

9. Project-Wide Deliverables

- 3D model (from integrated engineering platforms like AVEVA E3D, PDMS, or Smart 3D)

- Model review reports

- Clash reports and resolutions

- As-built drawing markups (for post-construction handover)

- Engineering design basis document

- Interface management documents

How Rishabh Engineering Supports FEED & Detailed Engineering in Multidisciplinary Projects?

Rishabh Engineering brings extensive experience and technical depth to support both FEED and Detailed Engineering phases of capital projects across industries such as oil & gas, chemicals, power, renewables, and infrastructure. With a proven track record of handling complex, multi-discipline engineering projects globally, the company acts as a reliable design partner to EPC/EPCM firms and asset owners.

Support During the FEED Phase

Rishabh Engineering ensures that the foundation of any project is laid correctly by offering the following key FEED services:

Scope & Requirement Definition

- Develop initial design basis, process philosophy, and design criteria.

- Assist in defining the project scope across all disciplines.

- Align engineering scope with client’s business goals and regulatory requirements.

Conceptual & Preliminary Design

- Generate process flow diagrams (PFDs), preliminary P&IDs.

- Prepare equipment and line sizing studies.

- Conduct preliminary layouts, site plans, and 3D model conceptualization.

Cost Estimation & Feasibility

- Generate discipline-wise BOQs and material take-offs.

- Provide engineering input to support accurate CAPEX & OPEX estimates.

- Analyze feasibility, constructability, and modularization opportunities.

Risk Identification & Mitigation

- Support HAZID/HAZOP reviews and operability studies.

- Conduct initial safety layout studies (e.g., hazardous area classification, escape routes).

- Address environmental, geotechnical, and seismic risks early in the design.

Interdisciplinary Coordination

- Ensure alignment between process, piping, mechanical, civil/structural, electrical, and instrumentation teams.

- Use integrated 3D tools like AVEVA E3D, SmartPlant, and Navisworks for early clash detection.

Support During the Detailed Engineering Phase

Once FEED is complete, Rishabh Engineering team seamlessly offer detailed engineering services to provide comprehensive, discipline-specific deliverables:

Civil & Structural Engineering

- Foundation and structural steel design.

- Detailed fabrication drawings and concrete layouts.

- Seismic and wind load analysis using STAAD.Pro, Tekla.

Mechanical & Equipment Engineering

- Datasheets, GA drawings, and mechanical calculations.

- Equipment loads data for foundations and steel structures.

- Review and integration of vendor documents.

Piping Engineering

- Finalized P&IDs, piping layouts, and isometric drawings.

- Pipe Stress analysis using CAESAR II.

- Pipe support design, tie-in details, MTOs.

Process Engineering

- Final heat & material balances, utility summaries.

- Equipment sizing, control narratives, and operating procedures.

- Relief system design and HAZOP participation.

Electrical Engineering

- Cable sizing, routing, and single-line diagrams (SLDs).

- Lighting, earthing, and power distribution layouts.

- Substation and MCC layouts.

Instrumentation & Control Engineering

- Instrument index, loop diagrams, I/O lists.

- Hook-up and termination drawings.

- DCS/PLC architecture and logic development.

Fire & Safety Engineering

- Firewater system layouts and calculations.

- Gas detection, emergency shutdown, and hazardous area layouts.

- Support for SIL studies and QRA modeling.

Construction & Procurement Support

- Construction Work Packages (CWPs).

- Technical bid evaluations and vendor drawing reviews.

- As-built updates, 3D modeling, and digital twin creation.

Final Words

In conclusion, FEED and detailed engineering work together to create the foundation of effective project delivery. With the help of a skilled multidisciplinary design engineering partner like Rishabh Engineering, these phases give each stage of the project lifecycle organization, accuracy, and synchronization. From thorough design integration and construction readiness through Detailed Engineering to precise scope definition and risk assessment during FEED, Rishabh assists clients in lowering rework, controlling expenses, and guaranteeing quality. They are a useful ally in the effective completion of challenging industrial projects because of their domain competence and cooperative style.

Need Expert Support For FEED Or Detailed Design?

Learn how a multidisciplinary approach can streamline execution, reduce risks, and drive project success.

Related Blogs

Related Blogs

Best Structural Engineering Software for Accurate Analysis

Finding tools that simplify and improve the accuracy of the…

Detailed Engineering Considerations for Project Success

Engineering projects today require meticulous planning and execution across various…