Front End Engineering Design For Multidiscipline Engineering Projects

Front End Engineering Design (FEED) is essential for multidisciplinary engineering projects, from oil and gas to power generation and petrochemicals. It places the framework for the whole project’s survival, ensuring smooth execution, budget adherence, and project success. In this article, we will discuss the importance of FEED, including its components, benefits, & processes, along with design deliverables, and how Rishabh Engineering can help you navigate seamlessly across them.

What Is Front End Engineering Design & Why Is It important?

It is a key step in the planning and developing industrial projects because it comprises conceptual design, the foundation for detailed engineering. It comprises preliminary engineering documents defining the project’s technical and economic components, including detailed design criteria, material and equipment specifications, and precise cost estimates. It serves as the foundation for all subsequent EPC processes. You would agree that a well-executed design would help reduce the risk by identifying potential concerns during the initial stages while assessing technical feasibility and ensuring the project’s profitability. Further, it would give stakeholders the input required to make informed decisions to plan finances and obtain required permissions and approvals.

Key Objectives Of Front-End Engineering And Design For Industrial Projects

It is a crucial phase in industrial projects that lays the groundwork for successful execution. The primary objectives of FEED include;

Project Definition And Scope Clarity

- Establish a comprehensive understanding of technical, operational, and financial aspects.

- Align all stakeholders with a clear project vision to reduce uncertainties.

Cost Estimation And Budgeting

- Develop accurate cost estimates and budgets based on detailed engineering studies.

- Consider potential risks and contingencies for better financial planning.

Risk Management

- Identify and assess technical, environmental, safety, and financial risks early.

- Mitigate risks to avoid costly changes and delays in later project stages.

Design Optimization

- Explore and evaluate design alternatives to ensure technical feasibility and cost-effectiveness.

- Align the design with overall project objectives.

Regulatory Compliance And Environmental Impact

- Ensure project design meets all regulatory requirements and environmental standards.

- Secure necessary permits and approvals for project sustainability.

Schedule Development

- Create a well-defined project schedule with key milestones and dependencies.

- Provide a clear roadmap for effective project execution and time management.

Stakeholder Alignment

- Foster collaboration among clients, contractors, and regulatory bodies.

- Align all parties on project goals, expectations, and deliverables.

Foundation For Detailed Engineering

- Provide essential information and documentation for subsequent procurement, construction, and commissioning activities.

- Lay the groundwork for detailed engineering design.

Value Engineering

- Incorporate value engineering principles to maximize project value.

- Identify cost-saving opportunities and enhance overall project efficiency.

Investment Decision Support

- Provide data and analysis to evaluate project feasibility and potential returns.

- Support informed investment decisions aligned with business objectives.

Benefits Of Front-End Engineering and Design

A comprehensive FEED approach offers numerous benefits to industrial projects:

- Improved project planning by allowing project teams to develop accurate plans & schedules of the project’s technical requirements, thus minimizing potential risks.

- Reduce costs by identifying opportunities that help facilitate value engineering solutions.

- Optimal quality by defining the project’s technical requirements in detail during FEED, thus improving the quality of engineering, procurement, and construction activities.

- Reduced risks by identifying them early, thus allowing mitigation strategies to develop and reduce delays and rework that prove to be costly.

- Regulatory compliance ensures that the proposed design aligns with relevant standards, thus reducing the chances of penalties and possible regulatory delays.

Front-End Engineering Design Process

Here’s an overview of the process:

- Project Definition & Scope: Gathering all necessary details, including design specifications, project goals, site conditions, regulatory requirements, and stakeholder expectations.

- Feasibility Studies: Conduct studies to evaluate different options for achieving goals, including site selection, technology options, and cost estimation.

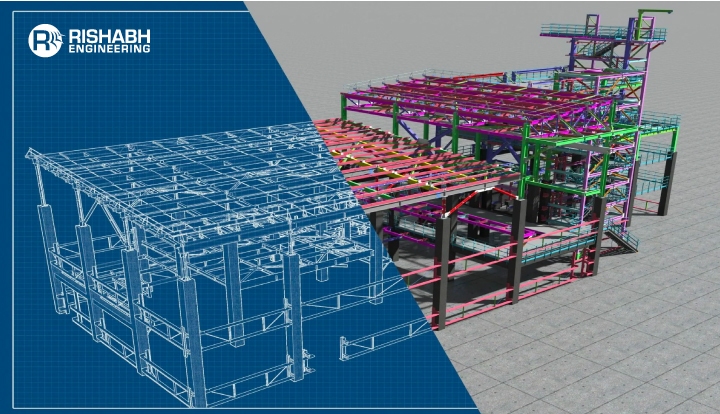

- Preliminary Design: Create block flow diagrams (BFDs), process flow diagrams (PFDs), and preliminary piping and instrumentation diagrams (P&IDs). This phase includes basic equipment sizing, initial 3D modeling, and layout planning. Thus, it would lay a foundation for more detailed designs later.

- Technology Selection: Evaluate and select technology options based on performance, reliability, cost, and compatibility with existing systems. This phase may include vendor evaluations, pilot testing, and licensing agreements.

- Cost Estimation: Prepare a capital expenditure (CAPEX) estimate, operating expenditure (OPEX) estimate, and contingency plans. Further, it involves detailed cost analysis, including materials, labor, equipment, and potential risks.

- Risk Assessment: Conduct assessments to identify potential technical, financial, safety, and environmental risks. Develop mitigation strategies, such as design changes, alternative materials, or additional safety measures.

- Project Scheduling: Create a project schedule that outlines key milestones, deliverables, and deadlines. This includes defining critical paths, resource allocation, and project phases from FEED through construction and commissioning.

- Detailed Design Basis: Compile a comprehensive design basis document, including all assumptions, specifications, codes, and standards. This document references the detailed engineering phase, ensuring consistency and accuracy.

- HSE (Health, Safety, and Environment) Review: Perform HSE reviews to identify potential hazards and environmental impacts. Implement safety and environmental protection measures, including safety instrumentation, emergency response plans, and waste management strategies.

- Documentation and Reporting: Prepare comprehensive documentation, including all design reports, drawings, cost estimates, risk assessments, and schedules. This documentation is crucial for securing project approval and funding.

- Client Review and Approval: Present the FEED package to the client and key stakeholders for review and approval. Address any concerns or requests for changes and finalize the design basis for the next phase.

- Transition to Detailed Engineering: Transition the project from FEED to detailed engineering by sharing all relevant documents, models, and data. The team also supports the detailed engineering squad during the initial stages to ensure a smooth handover.

Common Front-End Engineering Design Deliverables

FEED deliverables are usually standardized, though the depth and detail would vary depending on the project owner’s specific needs. Here’s a typical list of deliverables:

Preliminary Deliverables

Overall

- Scope of Work: Define the project’s boundaries and objectives.

- Project Schedule (Level 2): High-level timeline outlining key milestones.

- Total Installed Cost (TIC) Estimate: Preliminary cost estimation for the project.

Process

- Pressure Safety Valve (PSV) Sizing: Initial calculations for safety valves.

Civil/Structural

- Structural Design and Analysis/Sketches: Preliminary structural design concepts.

- Building Plans and Elevation: Initial layout of building structures.

Instrumentation and Electrical

- Distributed Control System (DCS) I/O Count: Estimate of input/output points for the control system.

- Spec Sheets: Preliminary specifications for instruments and electrical components.

Issued For Design (IFD) Deliverables

Process

- Process Flow Diagrams (PFDs): Detailed flowcharts of the process.

- Block Flow Diagram: High-level overview of the process flow.

- Heat and Material Balance (H&MB): Energy and material flow calculations.

- Process Drawing List: Inventory of all process-related drawings.

- Piping and Instrumentation Diagram (P&ID): Detailed piping and instrumentation diagrams.

- Hydraulic Study: Analysis of fluid dynamics in the system.

Mechanical/Piping

- Plot Plan: Layout of the site, including equipment and piping.

- Equipment Arrangement Plan: Detailed layout of equipment on-site.

- Utility Requirements: List of utilities needed for the project.

- 3D Model/Piping Plans: Visual model of the piping system.

- Line List: Inventory of piping lines with specifications.

- Tie-In List & Tie-In Location Plan: Details of connection points between new and existing systems.

- Global Material List: Overview of materials required.

- Major Equipment List & Data Sheets: Specifications and data sheets for key equipment.

- Outline Drawings: Preliminary equipment and piping sketches.

- Bid Tab for Major Equipment: Comparative analysis of bids for major equipment.

- Vendor Data Sheets: Detailed specifications from equipment vendors.

Civil/Structural

- Foundation Location Plan: Layout showing foundation locations.

- Foundation Sketches: Preliminary drawings of foundation designs.

- Steel/Concrete Estimation: Quantity estimation for structural materials.

Instrumentation And Electrical

- Instrumentation/Electrical Single-Line Diagrams (SLDs): Basic electrical schematics.

- Instrument Index: List of instruments used in the project.

- Major Electrical Equipment Details: Specifications of primary electrical equipment.

- Block Diagrams: High-level electrical circuit diagrams.

- Electrical Area Classification (EAC) Plans: Zoning based on electrical safety classifications.

- Cause and Effect (HAZOP): Analysis linking potential hazards to their causes.

- Motor List: Inventory of motors used in the project.

Note: The deliverables may vary based on client requirements, project drivers, and specific characteristics and risks of the project.

How Rishabh Engineering Can Help?

While FEED is the critical component of industrial project planning and execution, you need a comprehensive approach that provides numerous benefits, such as improved project planning, lower costs, higher quality, and increased stakeholder confidence. Collaboration with a reliable partner, such as Rishabh Engineering, may help ensure your project succeeds across all phases.

As an experienced multidiscipline engineering design company, we understand the importance of this process, which ensures the success of industrial projects. With a team of specialist engineers & designers, our detailed engineering services focus on Front End Engineering Design to meet your specific project needs. It would usually cover process design, mechanical design, electrical design, instrumentation, and control design, civil and structural design, safety and environmental assessments, cost projection, and project scheduling. Our services ensure that delivered packages are technically sound and aligned with the client’s goals. Partnering with Rishabh Engineering for your project would imply it is set for success from the beginning. Our hands-on experience in industrial projects and our commitment to quality make us the ideal partner for any engineering project.

Maximize Project Success With FEED

Partner with us for FEED and basic engineering to optimize project execution, costs, and risk management.

Related Blogs

Related Blogs

Detailed Engineering Considerations for Project Success

Engineering projects today require meticulous planning and execution across various…

Navigating the Green Hydrogen Value Chain

Green hydrogen is a powerful contender for a more sustainable…