Home / Basic Engineering/ Process Design Services

Process Design Services

Precision. Innovation. Reliability.

Process Design Services for Engineering Success

Rishabh Pro Engineering provides precise and efficient process design services for a variety of industries. We focus on developing safe, reliable, and energy-efficient systems, ensuring that every design meets project objectives and client expectations. Our team delivers tailored solutions that address both technical and commercial requirements, optimizing performance while adhering to the highest industry standards. We guide projects from initial concepts to final implementation, offering risk assessment, detailed schedules, and cost-effective design strategies.

We offer a full suite of process design services tailored to EPCs, PMCs, and Owner/Operators, including:

- Feasibility and conceptual process studies

- Development of Process Flow Diagrams (PFDs) and Piping & Instrumentation Diagrams (P&IDs)

- Material and heat balance calculations

- Process equipment sizing and data sheet preparation

- Relief and flare system design

- Hazard and operability (HAZOP) support

- Control philosophy and operating procedures

- Energy optimization and debottlenecking studies

Process Design Services We Offer

Pre-FEED (Conceptual & Basic Design) – FEL 1 Study

Pre-FEED (Conceptual & Basic Design) – FEL 1 Study

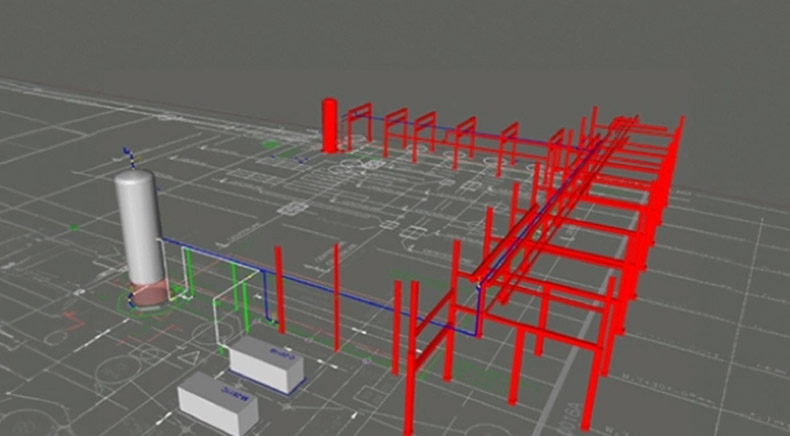

Operational Layouts

Early-stage process layouts to optimize plant efficiency

Core Design Framework Defining foundational technical and project design criteria

Major Process Overview Simplified representation of key process stages

Initial Equipment Sizing Preliminary sizing of essential equipment for the process

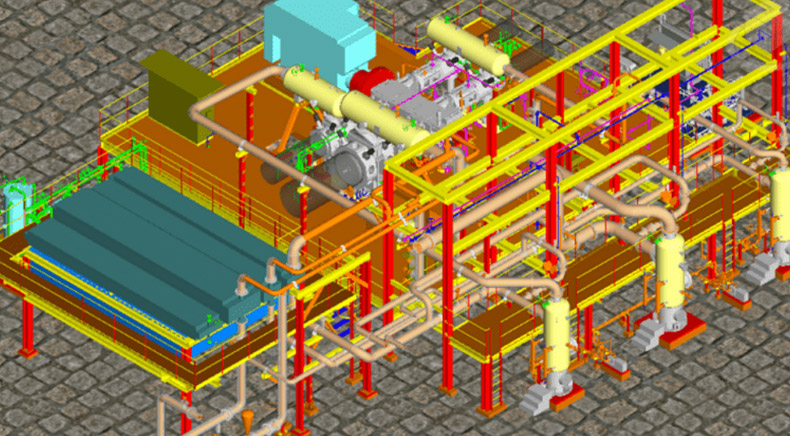

FEED Studies

FEED Studies

Project Scope Definition Establishing clear project boundaries and key deliverables

Design Efficiency Enhancement

Improving performance and reducing costs in project execution

Comprehensive Engineering Packages

All-inclusive multidisciplinary FEED outputs

Proactive Risk Management Identifying and addressing potential risks early

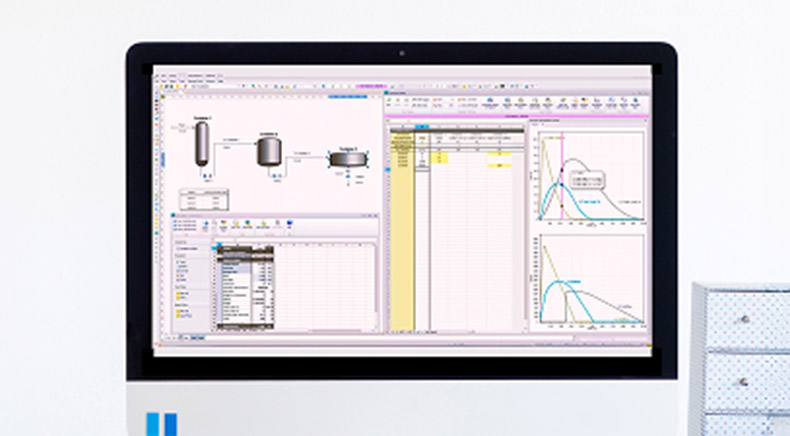

Simulation Modelling

Simulation Modelling

Plant Process Simulations Steady-state and dynamic simulations to model plant operations

Design Optimization Scenarios

Exploring alternative strategies for design and operation improvements

Energy and Material Flow Analysis

Precise heat and mass balance calculations for optimized performance

Equipment Performance Validation

Simulation-driven models for equipment rating and efficiency assessment

Feasibility Studies

Feasibility Studies

Cost Analysis

Analyzing CAPEX, OPEX, and ROI to determine project viability

Solution Comparison Exploring different scenarios to identify the most effective approach

Design Viability

Evaluating design suitability and identifying technical challenges

Sustainability Assessment Reviewing environmental impact and ensuring regulatory compliance

Technical Specifications

Technical Specifications

Material Standards & Selection

Defining construction and process material requirements

Supplier Deliverable Guidelines

Outlining expectations and standardized vendor submissions

Equipment Technical Datasheets

Providing detailed specifications for design and procurement

Engineering Design Basis Setting performance, safety, and design benchmarks

Project Planning ( L1 Schedule)

Project Planning ( L1 Schedule)

Project Activity Segmentation

Organizing project tasks into manageable units

Performance Monitoring Tracking and reporting project progress

Timeline Management Establishing project deadlines and critical milestones

Resource Optimization Efficiently managing manpower and materials

Cost Engineering (Class 4 Estimate)

Cost Engineering (Class 4 Estimate)

Capital & Operational Expense Evaluation

Comprehensive analysis of CAPEX and OPEX

Financial Forecasting Projecting cash flow needs throughout the project lifecycle

Budget Tracking

Ongoing monitoring of costs in alignment with project budgets

Design Optimization Enhancing cost efficiency through value engineering

Software Tools

Industries Served

Powering Multiple Sectors

Oil & Gas

Refinery & Petrochemicals

Hydrogen & Carbon Capture

Manufacturing

Cryogenics

Power Infrastructure

Specialty Chemicals

Water Wastewater Treatment

Industry Codes and Standards

- ASME B31.1

- ASME B31.3

- ASME B31.4 / B31.8

- API 520/521

- API 650 / 653

- NACE MR0175 / ISO 15156

- ASME Section VIII

- API 610

- API 617

- API 661

- ACI Codes

- AISC Codes

- ASTM Standards

- Eurocode / EN Standards

- IEC Standards

- IEEE Standards

- NFPA 70 / NEC

- ISA Standards

- API RP 500/505

- NFPA Standards – NFPA 30, 72, 85, 101

- OSHA Regulations

- EPA Standards

- ISO 31000

Ready to Optimize Your Plant Performance?

Partner with our process design engineering specialists to create safe, efficient, and cost-effective solutions for complex industrial operations.

Experienced & Trusted Process Design Company

Lower Lifecycle Costs

Optimized process design helps reduce the need for re-work and re-engineering, leading to significant cost savings throughout the entire project lifecycle.

Accelerated Plant Launch

A streamlined and efficient process design ensures quicker plant commissioning, enabling a faster operational handover and reducing time-to-market for critical operations.

Reduced Project Risks

Robust planning lowers technical, schedule, and budget uncertainties for smooth execution.

Improved Risk Management

Early identification and proactive mitigation strategies boost the overall reliability of the project.

Looking for a Reliable Design Engineering Partner?

We’re ready to collaborate. Get in touch to discuss how Rishabh Pro Engineering can support your next project.

Insights & Knowledge