Process Engineering in Manufacturing Industry

The focus of industrial manufacturing nowadays is on producing more efficiently, more sustainably, and intelligently rather than on producing the most. In the modern day and age rising operating expenses, increased global competitiveness, and pressure to implement greener practices are all putting pressure on manufacturers worldwide. On the plant floor, however, things are messy: unscheduled downtime throws delivery schedules off, waste reduces margins, bottlenecks slow down output, and quality is inconsistent. And this is where process engineering for the manufacturing industry becomes extremely useful. From the input of raw materials to the final products, businesses can increase efficiency, reduce costs, and improve quality by refining each step of the production process.

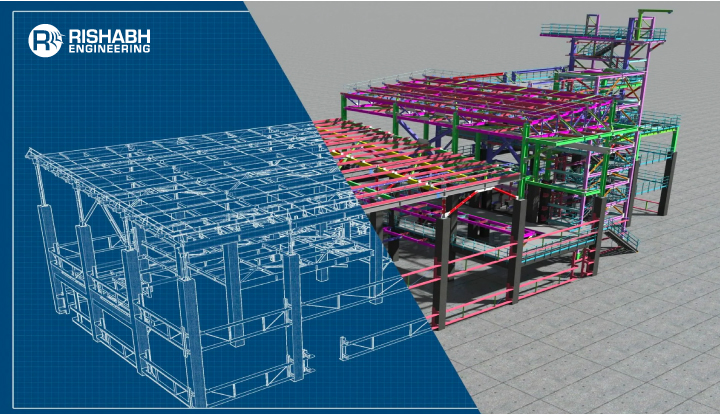

But here’s the key: process engineering as a discipline doesn’t exist in isolation. For it to truly work, it needs the combined power of multidiscipline engineering verticals including mechanical, civil, structural, electrical, instrumentation, and safety engineering coming together.

In this blog, we’ll cover specifics about process engineering in manufacturing industry, its importance, key services offered under this focus, applications & use cases, methodologies & tools, challenges encountered and how Rishabh Engineering team can help with real life case studies.

What is Process Engineering in Manufacturing?

At its heart, process engineering is about designing, analyzing, and continuously improving how things get made. It’s less about isolated machines and more about orchestrating the entire production ecosystem.

Process engineers focus on:

- Designing cost-efficient and scalable production systems.

- Analyzing workflows to uncover bottlenecks.

- Boosting throughput while reducing resource use.

- Embedding safety and compliance at every stage.

- Driving sustainability by minimizing waste and energy use.

But here’s where multidisciplinary support makes the difference: process engineers might design the workflow, but mechanical engineers ensure machines can handle the loads, civil and structural engineers plan the foundations for heavy equipment, electrical engineers power and automate it, while instrumentation engineers enable real-time monitoring. Together, they create a seamless, reliable system.

Importance of Process Engineering in the Manufacturing Industry

Multidiscipline design engineering ensures process optimization goes beyond theory. By combining process, mechanical, civil, electrical, structural, and instrumentation expertise, manufacturers achieve balanced, efficient, and scalable systems. This holistic approach minimizes downtime, improves safety, enhances energy efficiency, and enables seamless integration of modern automation technologies.

- Smarter Process Design & Optimization: Flowcharts are only one aspect of intelligent process design and optimization. Electrical and instrumentation professionals make sure that power distribution and control systems are completely synchronized, while process engineers may build a line. Structural and mechanical engineers improve layouts, equipment loads, and support structures. Low downtime and excellent throughput are the outcomes of this collaborative effort.

- Sustainable Development & Energy Efficiency: System-wide cooperation is required to meet sustainability objectives, not only equipment upgrades. To increase efficiency, process engineers may remove pointless steps, mechanical teams may optimize heat recovery, and civil teams may rearrange plant layouts. Together, they reduce energy demand and carbon footprint.

Key Services Offered by Process Engineering Teams

Process engineering teams enable manufacturing facilities with specialist services thus ensuring that systems are efficient, sustainable, and reliable. At their core, they bring together technical knowledge with practical industry experience to design, optimize, and maintain production processes.

Some of the essential services they provide include:

- Process Design & Development: From conceptual design to detailed engineering, process engineers develop workflows, layouts, and operating parameters for manufacturing facilities. They ensure that processes are not only cost-effective but also scalable, safe, and compliant with industry standards.

- Process Simulations & Feasibility Studies: By using advanced simulation tools, teams model processes virtually before physical implementation. This helps identify bottlenecks, evaluate “what-if” scenarios, and test the impact of potential changes. Feasibility studies provide valuable insights into capital investment, energy use, and long-term sustainability.

- Piping & Instrumentation Diagrams and Process Flow Diagrams: Creating accurate PFDs and P&IDs forms the backbone of any successful manufacturing setup. These visual blueprints map material and energy flows, equipment interconnections, and control systems—allowing teams to identify inefficiencies and ensure smooth integration.

- Process Optimization & Energy Management: Through rigorous analysis, engineers fine-tune processes to reduce waste, cut costs, and improve throughput. Energy audits and efficiency studies further ensure that plants operate with minimal environmental impact, aligning operations with sustainability goals.

- Safety & Risk Management: Process safety is integral to modern manufacturing. Teams perform hazard identification studies (HAZID), hazard and operability studies (HAZOP), and quantitative risk assessments (QRA) to ensure compliance with safety codes while protecting people, equipment, and the environment.

- Technology Integration & Automation Support: With the rise of Industry 4.0, process engineering teams help integrate digital technologies like IoT-enabled monitoring systems, predictive analytics, and automated control solutions. This ensures smarter decision-making and greater reliability in operations.

Applications of Process Engineering Across Manufacturing Sectors

Process engineering plays a critical role in a variety of manufacturing sectors, where efficiency, consistency, and sustainability are essential for success.

Let’s look at some of the use cases of how it applies to different segments of manufacturing industry.

- Automotive: Helps improve assembly lines and reduce production time. Engineers design optimized workflows, integrating robotics and automation to boost production rates while maintaining high quality and safety standards. By analyzing material flows and applying lean principles, manufacturers can cut waste and reduce costs, ensuring that every vehicle produced meets stringent quality controls.

- Food and Beverage: Ensures consistency in product quality while meeting safety and regulatory standards. Process engineers design systems that manage ingredient mixing, cooking, packaging, and storage efficiently, while minimizing energy usage and waste. For example, automation in packaging lines reduces human error, increases speed, and ensures hygiene standards are met.

- Pharmaceuticals and Healthcare: Focus is on designing systems that can scale from lab-based prototypes to full-scale production while maintaining quality and safety. Engineers optimize chemical processes, mixing, and packaging to ensure the active ingredients are distributed precisely, with minimal waste. Additionally, process engineers work closely with regulatory bodies to ensure all processes meet the necessary compliance standards.

- Electronics: Process engineers develop efficient workflows for producing semiconductors, circuit boards, and other complex electronic components. The application of automation and robotics ensures high throughput and precision. Further, process engineering also plays a role in cleanroom design, ensuring that contamination is minimized in sensitive environments and maximizing productivity.

- Energy and Renewable Sectors: For optimizing the production of energy, be it in traditional power plants or newer renewable energy technologies, process engineering enables engineers to focus on energy recovery, fuel efficiency, and integrating automation for predictive maintenance while increasing the uptime and reducing costs.

Across all these sectors, process engineering is not just about streamlining production—it’s about creating systems that evolve with technological advancements while continuously pushing for higher efficiency, lower environmental impact, and enhanced sustainability.

Process Engineering Methodologies and Tools

Process engineering uses PFDs, simulation, lean principles, and Six Sigma. These methods improve with multidisciplinary input. By combining process, mechanical, electrical, civil, and instrumentation expertise, manufacturers get practical designs. They also achieve smoother workflows and better results. The outcomes align with safety, sustainability, and performance goals.

- Process Flow Diagrams (PFDs): While process engineers map workflows, mechanical, civil, and electrical teams use these diagrams to validate designs against real-world constraints like space, power loads, or safety zones.

- Simulation & Modeling: Digital models aren’t just about flow efficiency, they’re tested against structural limits, electrical capacity, and safety regulations. A multidisciplinary approach makes virtual testing more realistic.

- Lean Principles: Waste elimination isn’t confined to production steps; it spans across structural layouts, material movement, energy consumption, and equipment design. Different disciplines work together to make lean more holistic.

- Six Sigma & Quality Control: Defects often come from multiple source design flaws, equipment limitations, or control system inconsistencies. Cross-disciplinary reviews help uncover and fix root causes faster.

Challenges in Process Engineering for Manufacturing

When faced with manufacturing issues, multidisciplinary teams contribute a variety of knowledge. Collaboration between process, mechanical, electrical, and structural disciplines help manufacturers overcome obstacles more quickly, safely, and efficiently, whether they are related to integrating modern automation with legacy systems, scaling lab-tested processes to full production, or guaranteeing consistent product quality.

- Growing from Pilot to Complete Manufacturing: A procedure that functions well in the lab frequently fails when used on a large scale. Businesses can scale easily by hiring process engineers for flow optimization, structural engineers for load assessments, and electrical teams for power requirements.

- Legacy System Integration: Retrofitting is challenging when integrating new technology with legacy systems. While mechanical engineers can prolong the life of equipment, instrumentation and electrical teams can create interfaces for legacy equipment that may not have modern control.

- Preserving Consistent Quality: Processes alone aren’t the only way to ensure quality. Real-time monitoring, machine tolerances, material qualities, and structural stability are all involved. It is simpler to maintain consistency when several technical specialties are present.

Why Partner with Rishabh Engineering for Process Engineering in Manufacturing Industry?

Rishabh Engineering can support manufacturing organizations across every stage by combining process expertise with the strength of multidisciplinary teams. Here’s how:

- Front-End Consulting & Feasibility: Process engineers analyze workflows, while mechanical and electrical teams validate equipment needs. Together, they provide clients with reliable forecasts of performance, costs, and risks.

- Process Design & Optimization: Civil and structural engineers design safe, efficient layouts, mechanical engineers optimize equipment placement, and process experts refine material flows—all ensuring minimal waste and downtime.

- Technology Integration & Automation: Instrumentation and electrical engineers integrate IoT, automation, and predictive analytics into the process flow designed by process engineers, making systems smarter and future ready.

- Quality & Safety Assurance: Safety isn’t just process-related, it’s structural, electrical, and mechanical too. Multidiscipline teams ensure compliance with codes and standards while embedding reliability into every layer.

Real Life Use Case:

Case Study: Optimizing TEG Dehydration in Natural Gas Transmission

The Client:

A US-Based Natural Gas Transmission Company.

Business Need

The client needed a comprehensive process simulation to optimize the operation of the Triethylene Glycol (TEG) dehydration unit in their natural gas transmission compressor booster station. The goal was to minimize moisture content in the dry gas outlet to prevent pipeline corrosion and maintain gas quality.

Scope of Work

- Conduct a detailed process simulation of the TEG dehydration unit.

- Analyze gas flow, operating temperature, and pressure to determine the optimal TEG circulation rate.

- Ensure moisture content in the dry gas is reduced to less than 6 lb/mmscf.

- Validate the glycol recirculation rate for system efficiency.

- Provide operational recommendations based on simulation results.

Challenges Addressed

- Achieving the target moisture content below 6 lb/mmscf.

- Ensuring an optimal glycol recirculation rate for efficient dehydration.

- Providing real-time operational recommendations based on simulations.

Software Tools Utilized

- CADWorx for 3D modeling.

- AutoCAD for 2D drafting.

- SolidWorks for sheet metal design and cold shoe FEA.

- STAAD.Pro for structural analysis.

- CAESAR II for pipe stress analysis.

- Tekla for structural fabrication drawings.

- Navisworks for 3D model review.

Final Words

The foundation of smarter, greener production lies in process engineering in manufacturing. With the help of a multidisciplinary design engineering method, its full potential becomes apparent. Manufacturing companies may create systems that are effective, safe, scalable, and prepared for the future by integrating the knowledge of process, mechanical, civil, structural, electrical, and instrumentation experts. Working with a multidisciplinary design engineering company that offers specialized process engineering services is not only prudent but also necessary in the current environment of narrow profit margins, stringent laws, and rising sustainability demands. It helps organizations to transform difficult problems into chances for long-term success and ongoing progress.

Partner With Process Engineering Specialists

Our team offer multidiscipline design engineering solutions to enable you with smarter, safer, and more sustainable manufacturing production systems.

Related Blogs

Related Blogs

Best Structural Engineering Software for Accurate Analysis

Finding tools that simplify and improve the accuracy of the…

Detailed Engineering Considerations for Project Success

Engineering projects today require meticulous planning and execution across various…